(Food waste as feedstock for 3D printed bioplastics)

2020/1/6 欧州委員会(EC)

・ EU の Bio-Based Industries Joint Undertaking(EU と Bio-based Industries Consortium 間の官民パートナーシップ)が資金を提供する BARBARA プロジェクトでは、農産物残渣の抽出物からバイオプラスチックを製造する技術を開発中。3D プリンティング技術である融解フィラメント製造(fused-filament fabrication: FFF)の原料として使用する。

・ 化石燃料由来の熱可塑性フィラメントを多機能のバイオ材料で代替し、化石燃料への依存、炭素排出量と埋立廃棄物量を低減すると共に、全く新しい循環型経済産業の興起に貢献する。

・ EUでは毎年約1 億1 千万トンの家畜や野菜の廃棄物が排出され、世界では全食品生産量の 33~ 50%が消費されずに廃棄されている。この課題の対処には、従来の食品加工・生産方法の抜本的な変革が必要と考える。

・ プラスチック袋やシングルユースプラスチック等の現行の商用バイオプラスチックは、機械的・熱的特性に劣るものが多い。同プロジェクトでは、より強く高価値なアプリケーションを目指す。

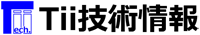

・ 同プロジェクトで開発するハイブリッド・ナノ-バイオコンポジット材料は、化学的に処理したトウモロコシ産業副産物のスターチ等のバイオ化合物と、レモン、アーモンドの殻とザクロからのバイオ添加物、そして無機補強剤より作製。

・ 新バイオポリマーは、高い衝撃強度と耐熱性を示し、抗菌性や発香等の特性の追加や様々な色を添加して製造できる。

・ 伊・フィアット研究センターと共同で車輌のドアハンドルとダッシュボードコンポーネントを 3D プリント作製する等、数種類のプロトタイプ・アプリケーションにて同バイオポリマーの試験を実施中。また、スペイン・アクシオナ・インフラストラクチャーと共同で、建築産業の厳格な熱的・機械的要件を満たす耐荷重トラスジョイントのモールドを開発中。

・ 同バイオポリマーによる最終製品ではコストを 40%、CO2 排出量を 20%それぞれ低減し、製造プロセス全体のサステナビリティーを大幅に向上させる。

・ 同プロジェクト終了時には、FFF製造に適したフィラメント用のバイオポリマー化合物を最低でも4種類完成させると共に、6 件の新しい製造プロセスと方法論の商用利用を目指す。これらには、農業食品廃棄物からの成分抽出と精製技術、最終的なバイオポリマーの熱的・機械的特性を化学的に強化するプロセス技術、そして 3D プリンティングプロセスとパーツのプリント技術が含まれる。

・ 本プロジェクトのパートナーであるメーカー企業、農業協同組合や主要な研究組織が、商業化に向けた農業食品廃棄物からの成分抽出プロセスと製造技術を評価し、革新的な新産業の展開につなげる。

URL: https://ec.europa.eu/research/infocentre/article_en.cfm?artid=51585

(関連情報)

BARBARA プロジェクト ウェブサイト

URL: https://www.barbaraproject.eu/

<NEDO海外技術情報より>

The BARBARA project, supported by the EU’s Bio-Based Industries Joint Undertaking, is developing novel bioplastics from extracts of vegetal residues for use in fused-filament fabrication (FFF), a versatile and widespread 3D printing technology. By enabling multifunctional biomaterials to replace filaments of fossil-derived thermoplastics in manufacturing, the research will not only reduce reliance on fossil fuels, cut carbon emissions and minimise landfill waste but can also stimulate entirely new circular-economy industries.

‘Agri-food residues and by-products, not only from crop harvesting but also from the processing and production of commercial food, are a major issue. EU countries produce around 110 million tonnes of animal and vegetal waste each year, while globally 33 to 50 % of all food produced is never eaten. To address these challenges, the traditional approach to food production and processing needs to undergo a fundamental transformation,’ says BARBARA coordinator Berta Gonzalvo Bas at AITIIP Centro Tecnológico in Spain.

Part of the solution envisioned by the BARBARA team is to use these renewable but until now unwanted agri-food resources in the preparation of advanced polymer materials for demanding engineering applications, substituting and improving upon unsustainable fossil-based plastics. Whereas most commercial bioplastics in use today, such as plastic bags or other small single-use items, have poor mechanical and thermal properties, the BARBARA researchers are targeting far more robust and high-value applications.

Better mechanical and thermal properties

By chemically engineering starch and similar biological compounds from corn industry by-products and incorporating bio-additives derived from lemon, almond husks and pomegranate as well as inorganic reinforcing agents, the team is developing hybrid nano-biocomposite materials. These novel biopolymers display high impact strength and thermal resistance and can be produced in diverse colours with additional features such as anti-bacterial or fragrance-releasing properties.

The new compounds are being tested in several prototype applications including 3D-printed car door handles and fascia dashboard components developed in collaboration with Centro Ricerche Fiat. Moulds for load-bearing truss joints that meet the building industry’s strict thermal and mechanical requirements are also being developed in collaboration with ACCIONA Infrastructure.

Scaled up, the BARBARA partners’ technologies could enable novel biopolymers, bioresins and bioadditives to become viable competitors to fossil-derived plastic materials that are currently produced – and discarded – in vast quantities worldwide.

‘Final products made with these biopolymers should result in a 40 % reduction in cost and 20 % reduction in CO2 emissions, thereby significantly increasing the sustainability of the overall manufacturing process,’ Gonzalvo Bas says.

By the end of the project, the project coordinator expects at least four biopolymer compounds to be suitable for producing filaments for FFF manufacturing, while six new production processes and methodologies will be closer to commercial viability. These include techniques for extracting and purifying compounds from agri-food waste, processes to chemically enhance the resulting polymers’ thermal and mechanical properties, and 3D printing processes and printing parts.

The partners, which include manufacturing firms, agricultural cooperatives and leading research institutes, plan to evaluate the agri-food extraction processes and manufacturing techniques for commercial exploitation, potentially developing innovative new industries.

‘The use of biobased and biodegradable materials combined with additives extracted from vegetal residues and by-products is considered to be one of the main pillars of the circular economy. We are transforming agri-food waste into a valuable resource,’ Gonzalvo Bas concludes.

BARBARA is funded through the Bio-Based Industries Joint Undertaking, a public-private partnership between the EU and the Bio-based Industries Consortium.

Project details

- Project acronym: BARBARA

- Participants: Spain (Coordinator), Sweden, Germany, Belgium, Italy

- Project N°: 745578

- Total costs: € 2 711 375

- EU contribution: € 2 603 861

- Duration: May 2017 to April 2020