2022-09-28 スウェーデン王国・王立工科大学(KTH)

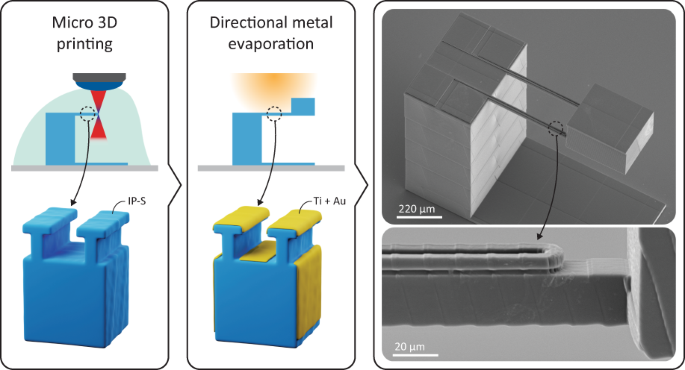

シャドウマスキングと呼ばれる、ステンシルのような手法を使用して、変換素子を形成する。

この方法を用いれば、比較的安価な市販の製造装置を用いて、カスタム設計のMEMS加速度ピックアップを10数個製造するのに数時間しかかからない。

この方法は、MEMSデバイスの試作や、年間数万から数千個のMEMSセンサーの中小ロットの製造に、経済的に実現可能である。

<関連情報>

- https://www.kth.se/en/om/nyheter/centrala-nyheter/3d-printing-can-now-manufacture-customized-sensors-for-robots-pacemakers-and-more-1.1194889

- https://www.nature.com/articles/s41378-022-00440-9

マイクロ3Dプリンティングによる機能性MEMS加速度センサーの実現 Micro 3D printing of a functional MEMS accelerometer

Simone Pagliano,David E. Marschner,Damien Maillard,Nils Ehrmann,Göran Stemme,Stefan Braun,Luis Guillermo Villanueva & Frank Niklaus

Nature Microsystems & Nanoengineering Published:19 September 2022

DOI:https://doi.org/10.1038/s41378-022-00440-9

Abstract

Microelectromechanical system (MEMS) devices, such as accelerometers, are widely used across industries, including the automotive, consumer electronics, and medical industries. MEMS are efficiently produced at very high volumes using large-scale semiconductor manufacturing techniques. However, these techniques are not viable for the cost-efficient manufacturing of specialized MEMS devices at low- and medium-scale volumes. Thus, applications that require custom-designed MEMS devices for markets with low- and medium-scale volumes of below 5000–10,000 components per year are extremely difficult to address efficiently. The 3D printing of MEMS devices could enable the efficient realization and production of MEMS devices at these low- and medium-scale volumes. However, current micro-3D printing technologies have limited capabilities for printing functional MEMS. Herein, we demonstrate a functional 3D-printed MEMS accelerometer using 3D printing by two-photon polymerization in combination with the deposition of a strain gauge transducer by metal evaporation. We characterized the responsivity, resonance frequency, and stability over time of the MEMS accelerometer. Our results demonstrate that the 3D printing of functional MEMS is a viable approach that could enable the efficient realization of a variety of custom-designed MEMS devices, addressing new application areas that are difficult or impossible to address using conventional MEMS manufacturing.