2026-01-21 産業技術総合研究所

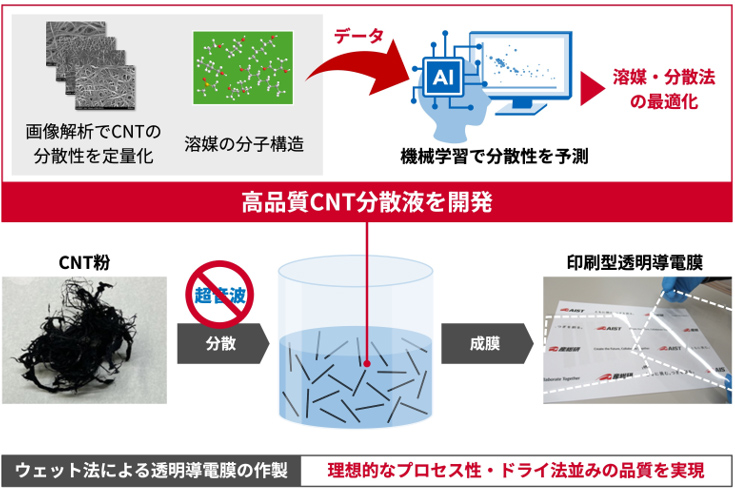

AIが導くCNT分散プロセス最適化

<関連情報>

- https://www.aist.go.jp/aist_j/press_release/pr2026/pr20260121/pr20260121.html

- https://advanced.onlinelibrary.wiley.com/doi/full/10.1002/adfm.202524038

データ駆動型およびメカニズムに基づく印刷可能なカーボンナノチューブ透明導電膜の合理的設計 Rational Design of Printable Carbon Nanotube Transparent Conductive Films via Data-Driven and Mechanistic Insights

Ying Zhou, Ken-ichi Nomura, Shun Muroga, Makoto Yoneya, Don N. Futaba, Takeo Yamada, Reiko Azumi, Kenji Hata

Advanced Functional Materials Published: 21 January 2026

DOI:https://doi.org/10.1002/adfm.202524038

ABSTRACT

Achieving controlled dispersion and assembly of carbon nanotubes (CNTs) is a fundamental challenge that underpins their broad application in electronics, optics, and energy storage devices. Transparent conductive films (TCFs) used in touch panels and flexible electronics serve as a model system for highlighting the importance of dispersion-state engineering. Despite their excellent electrical and optical properties, CNTs are difficult to exfoliate into fine bundles without introducing structural damage, particularly under scalable, solution-based processing. In this study, we present a data-guided strategy for the rational design of CNT dispersions. By combining machine learning models trained on exfoliation datasets with molecular simulations and solubility parameter analysis, we identify effective solvent systems for use with an acidic polymer dispersant. This approach enables a mild, non-sonication process that preserves CNT length and structural integrity, yielding uniform networks. The resulting CNT TCFs exhibit high crystallinity (G/D > 160), low sheet resistance (35 Ω sq−1 at 90.2% transmittance), and fine-line printability below 20 µm. This work demonstrates how data-driven and mechanistic insights into dispersion can be leveraged to produce printable, high-performance CNT films. Moreover, the methodology offers a versatile framework for scalable, industrially relevant CNT dispersion and assembly, with broad applicability to nanomaterials processing and solvent-processed device fabrication.