2023-10-04 ジョージア工科大学

◆彼らのプロセスは、印刷したポリマーレジンをシリカガラスに変換するために必要な熱を、摂氏1,100度から約摂氏220度に減少させ、硬化時間を半日以上からわずか5時間に短縮します。彼らは、人間の髪の毛の幅程度の小さなレンズを含むあらゆる種類のガラス微細構造物を製造するためにこれを使用し、これらは体内の医療画像診断に利用できる可能性があります。

<関連情報>

- https://research.gatech.edu/new-process-3d-prints-glass-microstructures-low-temperature-fast-curing

- https://www.science.org/doi/10.1126/sciadv.adi2958

透明シリカガラス微細構造の低温3Dプリンティング Low-temperature 3D printing of transparent silica glass microstructures

Mingzhe Li,Liang Yue ,Arunkumar Chitteth Rajan,Luxia Yu,Harikrishna Sahu,S. Macrae Montgomery,Rampi Ramprasad,and H. Jerry Qi

Science Advances Published:4 Oct 2023

DOI:https://doi.org/10.1126/sciadv.adi2958

Abstract

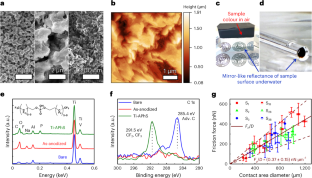

Transparent silica glass is one of the most essential materials used in society and industry, owing to its exceptional optical, thermal, and chemical properties. However, glass is extremely difficult to shape, especially into complex and miniaturized structures. Recent advances in three-dimensional (3D) printing have allowed for the creation of glass structures, but these methods involve time-consuming and high-temperature processes. Here, we report a photochemistry-based strategy for making glass structures of micrometer size under mild conditions. Our technique uses a photocurable polydimethylsiloxane resin that is 3D printed into complex structures and converted to silica glass via deep ultraviolet (DUV) irradiation in an ozone environment. The unique DUV-ozone conversion process for silica microstructures is low temperature (~220°C) and fast (<5 hours). The printed silica glass is highly transparent with smooth surface, comparable to commercial fused silica glass. This work enables the creation of arbitrary structures in silica glass through photochemistry and opens opportunities in unexplored territories for glass processing techniques.