2023-04-18 パシフィック・ノースウェスト国立研究所(PNNL)

軽量のアルミニウムは、EVの走行距離を延ばすことができます。ShAPE™プロセスは、スクラップのかけらや残りのアルミニウムの切りくずを収集し、新しい車両部品に適した素材に直接変換する特許取得済みの製造プロセスです。

<関連情報>

- https://www.pnnl.gov/news-media/recycled-aluminum-offers-energy-emissions-and-electric-vehicle-battery-range-savings

- https://www.sciencedirect.com/science/article/pii/S2213846323000111

アルミニウム6063産業スクラップのせん断アシスト加工と押出成形によるポルトホールダイス押出成形 Porthole die extrusion of aluminum 6063 industrial scrap by shear assisted processing and extrusion

Scott Whalen, Brandon Scott Taysom, Nicole Overman, Md. Reza-E-Rabby, Yao Qiao, Thomas Richter, Timothy Skszek, Massimo DiCiano

Manufacturing Letters Available online :28 March 2023

DOI:https://doi.org/10.1016/j.mfglet.2023.01.005

Highlights

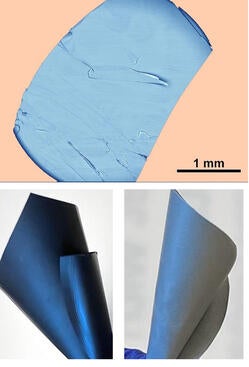

•Integrated a rotating porthole extrusion within Shear Assisted Processing and Extrusion to form noncircular, asymmetric, multi-cell profiles.

•Extruded aluminum alloy 6063 cast billets made from 100% industrial scrap.

•Achieved highly refined microstructure with an average grain size of 6.7 µm.

•Attained yield strength of 247 ± 10.4 MPa, ultimate tensile strength of 271 ± 9.6 MPa, and uniform elongation of 16.5 ± 2.4% from aluminum alloy 6063 industrial scrap.

Abstract

Shear Assisted Processing and Extrusion (ShAPE) is presented as a new manufacturing technology for converting aluminum scrap directly into extruded products. In this work, a porthole die configuration is integrated within the rotating ShAPE process to extrude circular, square, trapezoidal, and two-cell trapezoidal profiles from aluminum alloy 6063 industrial scrap. Microstructural characterization is presented for a trapezoidal profile having an average grain size of 6.7 µm in the as-extruded condition. Round tubes achieved yield strength (246.9 ± 10.4 MPa), ultimate tensile strength (270.8 ± 9.6 MPa), and uniform elongation (16.5 ± 2.4%) exceeding industry standards.