2023-10-10 カリフォルニア大学バークレー校(UCB)

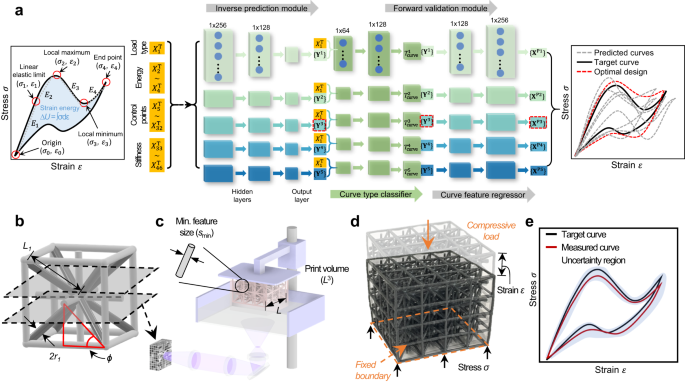

◆このAIベースの設計アプローチは、高性能材料の開発、製造プロセスの簡素化、新しい機械的特性を持つ材料の開発を可能にし、機器や製品の設計を大幅に助ける可能性があります。これにより、材料の作成にAIと3Dプリンターを活用し、ユーザーが所望の製品の機械的挙動を定義し、その他の作業はAIと3Dプリンターに委ねることができます。これにより、AIベースの設計方法が製品の機械的挙動を正確に再現できます。

<関連情報>

- https://engineering.berkeley.edu/news/2023/10/researchers-develop-new-ai-based-design-method-for-metamaterials/

- https://www.nature.com/articles/s41467-023-40854-1

機械学習による所定の機械的挙動に基づくメタマテリアルの迅速な逆設計 Rapid inverse design of metamaterials based on prescribed mechanical behavior through machine learning

Chan Soo Ha,Desheng Yao,Zhenpeng Xu,Chenang Liu,Han Liu,Daniel Elkins,Matthew Kile,Vikram Deshpande,Zhenyu Kong,Mathieu Bauchy & Xiaoyu (Rayne) Zheng

Nature Communications Published:18 September 2023

DOI:https://doi.org/10.1038/s41467-023-40854-1

Abstract

Designing and printing metamaterials with customizable architectures enables the realization of unprecedented mechanical behaviors that transcend those of their constituent materials. These behaviors are recorded in the form of response curves, with stress-strain curves describing their quasi-static footprint. However, existing inverse design approaches are yet matured to capture the full desired behaviors due to challenges stemmed from multiple design objectives, nonlinear behavior, and process-dependent manufacturing errors. Here, we report a rapid inverse design methodology, leveraging generative machine learning and desktop additive manufacturing, which enables the creation of nearly all possible uniaxial compressive stress‒strain curve cases while accounting for process-dependent errors from printing. Results show that mechanical behavior with full tailorability can be achieved with nearly 90% fidelity between target and experimentally measured results. Our approach represents a starting point to inverse design materials that meet prescribed yet complex behaviors and potentially bypasses iterative design-manufacturing cycles.