2025-02-03 ハーバード大学

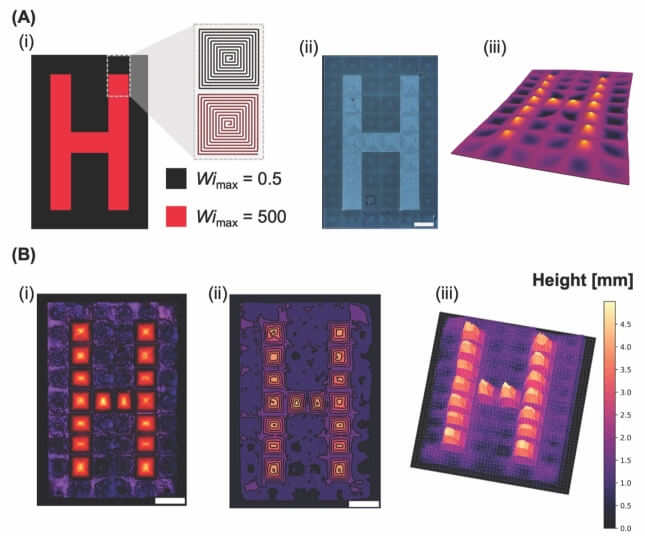

The researchers demonstrated on-the-fly control of liquid crystal molecular alignment by printing ‘H’ shapes. Red consists of highly aligned molecules while black consists of poorly aligned molecules.

<関連情報>

- https://seas.harvard.edu/news/2025/02/encoding-many-properties-one-material-3d-printing

- https://www.pnas.org/doi/10.1073/pnas.2414960122

印刷された液晶エラストマーにおける空間的にプログラムされた配列と作動 Spatially programmed alignment and actuation in printed liquid crystal elastomers

Rodrigo Telles, Arda Kotikian, Guillaume Freychet, +7, and Jennifer A. Lewis

Proceedings of the National Academy of Sciences Published:January 15, 2025

DOI:https://doi.org/10.1073/pnas.2414960122

Significance

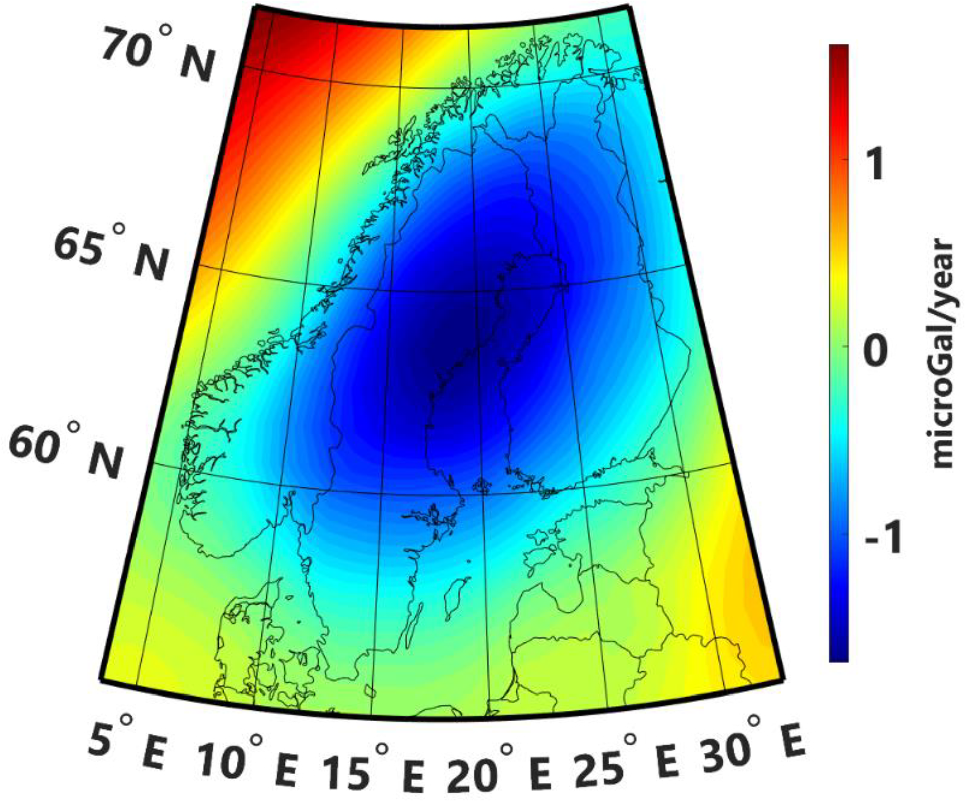

Aligned liquid crystal elastomers (LCE) are soft materials that exhibit reversible actuation akin to human muscles when thermally cycled above their nematic-to-isotropic transition temperature. Here, we report the effects of LCE ink composition, nozzle geometry, and printing parameters on director alignment. By combining rheological measurements, in operando microbeam X-ray scattering, and simulation, we show that the dimensionless Weissenberg (Wi) number, which characterizes ink flow through tapered and hyperbolic nozzles, directly correlates with director alignment in printed LCE filaments. By altering the value of Wi on-the-fly during printing, one can fabricate monolithic LCE actuators with spatially programmable alignment, stiffness, and shape morphing behavior.

Abstract

Liquid crystal elastomers (LCEs) exhibit reversible shape morphing behavior when cycled above their nematic-to-isotropic transition temperature. During extrusion-based 3D printing, LCE inks are subjected to coupled shear and extensional flows that can be harnessed to spatially control the alignment of their nematic director along prescribed print paths. Here, we combine experiment and modeling to elucidate the effects of ink composition, nozzle geometry, and printing parameters on director alignment. From rheological measurements, we quantify the dimensionless Weissenberg number (Wi) for the flow field each ink experiences as a function of printing conditions and demonstrate that Wi is a strong predictor of LCE alignment. We find that director alignment in LCE filaments printed through a tapered nozzle varies radially when Wi < 1, while it is uniform when Wi ≫ 1. Based on COMSOL simulations and in operando X-ray measurements, we show that LCE inks printed through nozzles with an internal hyperbolic geometry exhibit a more uniform director alignment for a given Wi compared to those through tapered nozzles. Concomitantly, the stiffness along the print direction and actuation strain of printed LCEs increases substantially under such conditions. By varying Wi during printing through adjusting the flow rate “on the fly”, LCE architectures with uniform composition, yet locally encoded shape morphing transitions can be realized.