2025-06-30 テキサス大学オースチン校 (UT Austin)

<関連情報>

- https://news.utexas.edu/2025/06/30/3d-printing-breakthrough-paves-way-for-next-gen-medical-devices-and-stretchable-electronics/

- https://www.nature.com/articles/s41563-025-02249-z

- https://pubs.acs.org/doi/10.1021/acscentsci.5c00289

波長選択性マルチマテリアル3Dプリンティング用ハイブリッドエポキシ-アクリレート樹脂 Hybrid epoxy–acrylate resins for wavelength-selective multimaterial 3D printing

Ji-Won Kim,Marshall J. Allen,Elizabeth A. Recker,Lynn M. Stevens,Henry L. Cater,Ain Uddin,Ang Gao,Wyatt Eckstrom,Anthony J. Arrowood,Gabriel E. Sanoja,Michael A. Cullinan,Benny D. Freeman & Zachariah A. Page

Nature Materials Published:30 June 2025

DOI:https://doi.org/10.1038/s41563-025-02249-z

Abstract

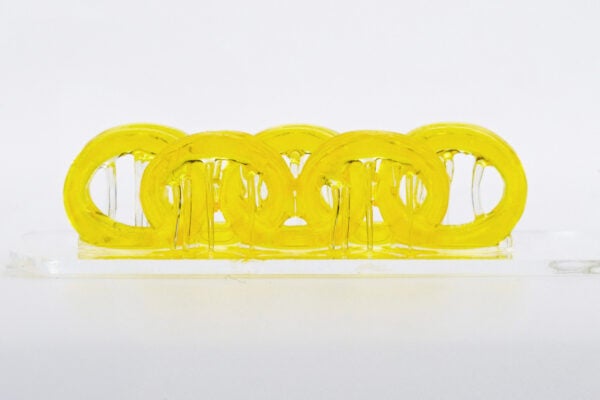

Structures in nature combine hard and soft materials in precise three-dimensional (3D) arrangements, imbuing bulk properties and functionalities that remain elusive to mimic synthetically. However, the potential for biomimetic analogues to seamlessly interface hard materials with soft interfaces has driven the demand for innovative chemistries and manufacturing approaches. Here, we report a liquid resin for rapid, high-resolution digital light processing (DLP) 3D printing of multimaterial objects with an unprecedented combination of strength, elasticity and resistance to ageing. A covalently bound hybrid epoxy–acrylate monomer precludes plasticization of soft domains, while a wavelength-selective photosensitizer accelerates cationic curing of hard domains. Using dual projection for multicolour DLP 3D printing, bioinspired metamaterial structures are fabricated, including hard springs embedded in a soft cylinder to adjust compressive behaviour and a detailed knee joint featuring ‘bones’ and ‘ligaments’ for smooth motion. Finally, a proof-of-concept device demonstrates selective stretching for electronics.

多色デジタル光造形3Dプリンティングにより、自立型および非組立型構造物の分解可能なサポートが可能になる Multicolor Digital Light Processing 3D Printing Enables Dissolvable Supports for Freestanding and Non-Assembly Structures

Keldy S. Mason,Ji-Won Kim,Elizabeth A. Recker,Jenna M. Nymick,Mingyu Shi,Franz A. Stolpen,Jaechul Ju,and Zachariah A. Page

ACS Central Science Published: May 29, 2025

DOI:https://doi.org/10.1021/acscentsci.5c00289

Abstract

The limited diversity in photocurable resin chemistries has precluded access to certain geometries using digital light processing (DLP) 3D printing, a rapid, precise, economical, and low-waste manufacturing technology. Specifically, freestanding structures with floating overhangs (e.g., hooks) and mobile nonassembly structures that cannot be physically separated (e.g., joints) represent two such geometries that are difficult or impossible to access with contemporary DLP 3D printing. Herein, we disclose novel resins that selectively react with different colors of light to form soluble thermoplastics and insoluble thermosets. Systematic characterization of the acrylate- and epoxy-based resins and corresponding polymers from simultaneous UV and visible (violet or blue) light exposure revealed a rapid multimaterial 3D printing process (∼0.75 mm/min) capable of providing supports that dissolve in ethyl acetate, a “green” solvent, within 10 min at room temperature. Relative to manual support removal, the present process provides comparable or improved surface finishes and higher throughput. Finally, several proof-of-concept structures requiring dissolvable supports were 3D printed, including hooks, chains, and joints, which were scanned using computed tomography to showcase the process’s geometric versatility and high fidelity. This work provides fundamental design principles for multimaterial resin chemistry and lays a foundation for automating next generation additive manufacturing.