2025-06-12 東京大学

<関連情報>

- https://www.t.u-tokyo.ac.jp/press/pr2025-06-12-001

- https://www.t.u-tokyo.ac.jp/hubfs/press-release/2025/0612/001/text.pdf

- https://www.science.org/doi/10.1126/sciadv.adv4436

過渡電子励起による透明材料の超高速レーザー穿孔 Ultrahigh-speed laser drilling of transparent materials via transient electronic excitation

Yanming Zhang, Takumi Koike, Reina Yoshizaki, Guoqi Ren, […] , and Yusuke Ito

Science Advances Published:11 Jun 2025

DOI:https://doi.org/10.1126/sciadv.adv4436

Abstract

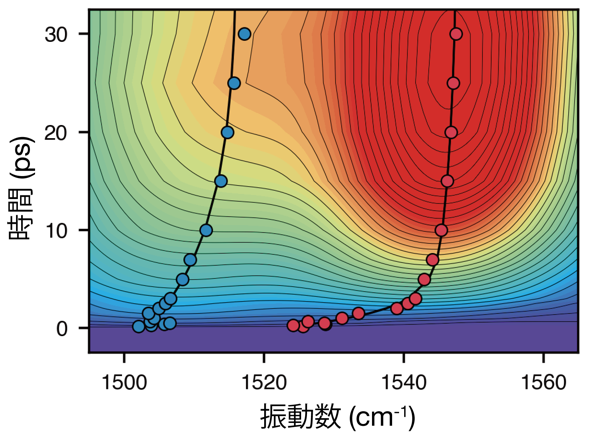

Femtosecond lasers with extremely high peak intensity have driven remarkable advancements in manufacturing across science, medicine, and industry. However, the problem of notably low machining speed remains unsolved. Here, we demonstrate that by transiently exciting electrons in a transparent material, the laser drilling speed is increased by a factor of 1 million compared to that in multishot percussion drilling. By irradiating with a single shot of a spatially shaped ultrashort laser pulse, the optical properties are momentarily changed on the picosecond scale, making the material considerably easier to machine by a successive laser pulse. The selective absorption of laser energy in regions with excited electrons leads to the rapid heating and evaporation of material at an extraordinarily high speed. Furthermore, the machining is achieved using a low-power light source, four orders of magnitude lower than conventional femtosecond lasers. The concept of transiently altering material properties is expected to usher in a paradigm shift in research and development for manufacturing.