2025-04-04 東京大学

<関連情報>

- https://www.t.u-tokyo.ac.jp/press/pr2025-04-04-001

- https://www.t.u-tokyo.ac.jp/hubfs/press-release/2025/0404/001/text.pdf

- https://www.nature.com/articles/s41560-025-01751-7

実験室規模の小型電池を用いた加速熱量測定による迅速な安全性スクリーニングの実現 Rapid safety screening realized by accelerating rate calorimetry with lab-scale small batteries

Seongjae Ko,Hiromi Otsuka,Shin Kimura,Yuta Takagi,Shoji Yamaguchi,Takuya Masuda & Atsuo Yamada

Nature Energy Published:02 April 2025

DOI:https://doi.org/10.1038/s41560-025-01751-7

Abstract

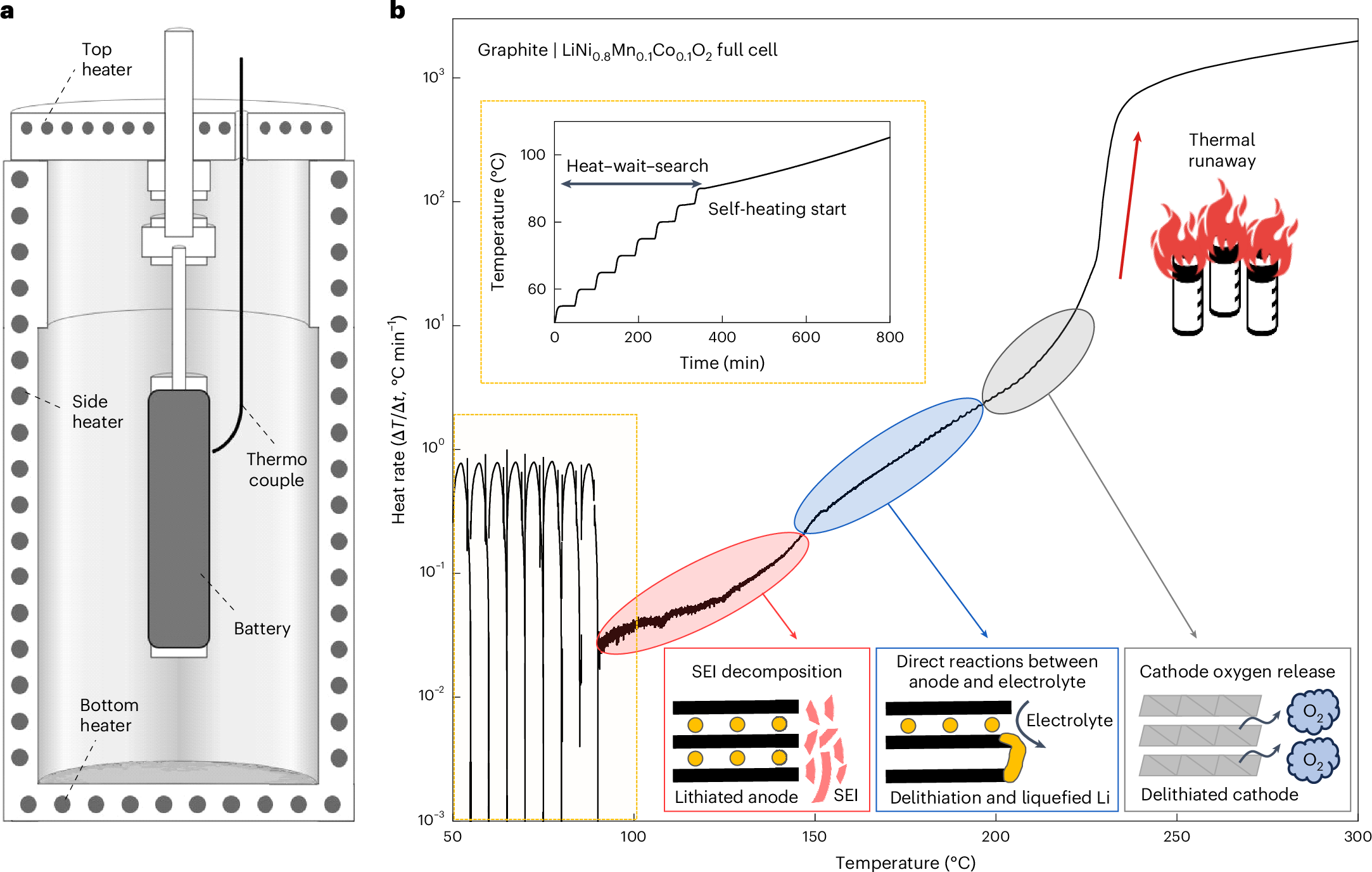

The increasing energy density and size requirements have necessitated the establishment of reliable safety technologies for rechargeable batteries. In particular, understanding and controlling thermal runaway, an uncontrollable heat generation from continuous exothermic reactions in batteries, is essential for developing high-safety batteries. However, comprehensive safety evaluations at the full-cell level are limited by size requirements (greater than the ampere-hour scale) for performing accelerating rate calorimetry tests that can provide critical information on heat generation during thermal runaway. Further, efficient safety screening is difficult because of substantial quantities of battery materials and costly manufacturing processes. Here we designed cylindrical pouch-type small batteries (~21 mAh, ~0.1 g of cathode active materials) that are highly susceptible to heat generation, thus allowing us to perform full-cell-level accelerating rate calorimetry tests on a laboratory scale. This enables rapid safety screening and early-stage feedback for battery design, which can help accelerate the development of high-safety batteries.