2024-04-16 オークリッジ国立研究所(ORNL)

<関連情報>

- https://www.ornl.gov/news/chemists-invent-more-efficient-way-extract-lithium-mining-sites-oil-fields-used-batteries

- https://pubs.acs.org/doi/10.1021/acsami.3c12070

- https://pubs.acs.org/doi/10.1021/acs.jpcc.3c05676

リチウム直接抽出のための統合循環経済モデルシステム: 水酸化アルミニウムを利用した鉱物から電池へ Integrated Circular Economy Model System for Direct Lithium Extraction: From Minerals to Batteries Utilizing Aluminum Hydroxide

K. Jayanthi, Tej N. Lamichhane, Venkat Roy, Fu Zhao, Alexandra Navrotsky, Bruce A. Moyer, and Mariappan Parans Paranthaman

ACS Applied Materials & Interfaces Published:December 5, 2023

DOI:https://doi.org/10.1021/acsami.3c12070

Abstract

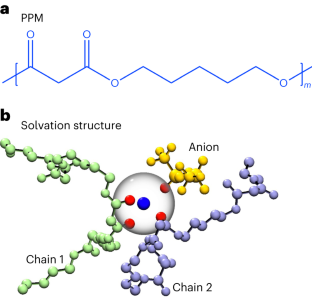

Aluminum hydroxide, an abundant mineral found in nature, exists in four polymorphs: gibbsite, bayerite, nordstrandite, and doyleite. Among these polymorphs gibbsite, bayerite, and commercially synthesized amorphous aluminum hydroxide have been investigated as sorbent materials for lithium extraction from sulfate solutions. The amorphous form of Al(OH)3 exhibits a reactivity higher than that of the naturally occurring crystalline polymorphs in terms of extracting Li+ ions. This study employed high-temperature oxide melt solution calorimetry to explore the energetics of the sorbent polymorphs. The enthalpic stability order was measured to be gibbsite > bayerite > amorphous Al(OH)3. The least stable form, amorphous Al(OH)3, undergoes a spontaneous reaction with lithium, resulting in the formation of a stable layered double hydroxide phase. Consequently, amorphous Al(OH)3 shows promise as a sorbent material for selectively extracting lithium from clay mineral leachate solutions. This research demonstrates the selective direct extraction of Li+ ions using amorphous aluminum hydroxide through a liquid–solid lithiation reaction, followed by acid-free delithiation and relithiation processes, achieving an extraction efficiency of 86%, and the maximum capacity was 37.86 mg·g–1 in a single step during lithiation. With high selectivity during lithiation and nearly complete recoverability of the sorbent material during delithiation, this method presents a circular economy model. Furthermore, a life cycle analysis was conducted to illustrate the environmental advantages of replacing the conventional soda ash-based precipitation process with this method, along with a simple operational cost analysis to evaluate reagent and fuel expenses.

Li-Al層状複水酸化物の脱リチウム化における陰イオンの効果: 熱力学的洞察 Effect of Anions on the Delithiation of [Li–Al] Layered Double Hydroxides: Thermodynamic Insights

K. Jayanthi, Mariappan Parans Paranthaman, Benjamin T. Manard, and Alexandra Navrotsky

The Journal of Physical Chemistry C Published:December 5, 2023

DOI:https://doi.org/10.1021/acs.jpcc.3c05676

Abstract

The utilization of lithium aluminum [Li–Al] layered double hydroxides (LDHs) is explored for direct lithium extraction (DLE) from geothermal brines and minerals. Following extraction, the Li+ ions need to be removed from the LDH structure and converted into LiOH or Li2CO3 products, making them suitable for battery applications. The research investigates the delithiation of [Li–Al-X] LDHs (where X = Cl–, OH–, and SO42–), which were synthesized and dried under different conditions. The study aims to understand how the choice of anions and drying conditions affects the delithiation process. To determine the stability of these [Li–Al] LDHs, high-temperature oxide melt solution calorimetry is employed. The results reveal that the stability of LDHs varies significantly based on postdrying conditions, anion choice, and the water content in the interlayer. The order of stability, as indicated by the enthalpy of formation values, is found to be OH-LDH-O > OH-LDH-A > SO4-LDH-O > SO4-LDH-A > Cl-LDH-O > Cl-LDH-A. This trend is attributed to the interactions among the interlayer species and the metal hydroxide layers.