2024-03-20 パシフィック・ノースウェスト国立研究所(PNNL)

<関連情報>

- https://www.pnnl.gov/news-media/understanding-corrosion-enable-next-generation-metals

- https://www.nature.com/articles/s41598-023-42249-0

- https://www.nature.com/articles/s41598-023-39961-2

- https://pubs.acs.org/doi/full/10.1021/acs.jpcc.2c03807

シンプルで汎用性の高い現場マルチモーダル腐食測定システムによる腐食のプロービング Probing corrosion using a simple and versatile in situ multimodal corrosion measurement system

Sridhar Niverty,Rajib Kalsar,Robert J. Seffens,Anthony D. Guzman,Timothy J. Roosendaal,Lyndi Strange & Vineet V. Joshi

Scientific Reports Published:04 October 2023

DOI:https://doi.org/10.1038/s41598-023-42249-0

Abstract

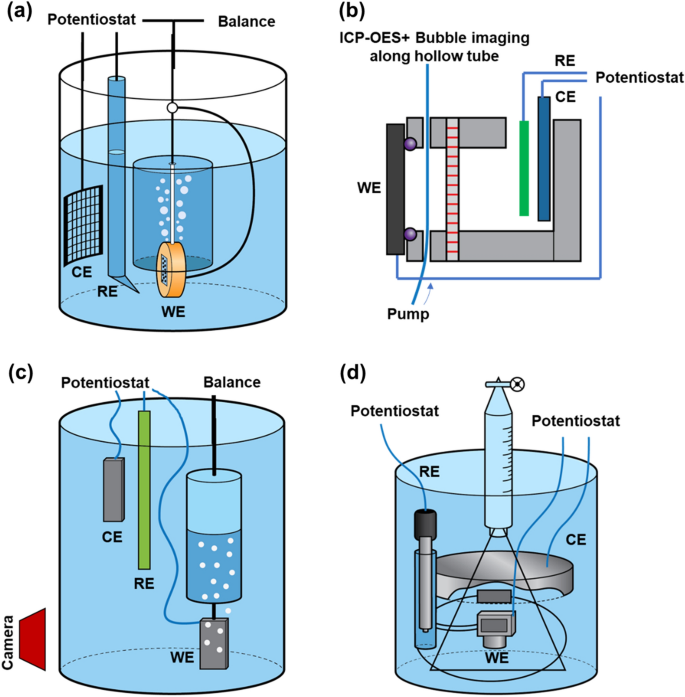

In this work, we have developed a unique in situ multimodal corrosion system that is capable of acquiring electrochemical data, sample imaging/visualization and hydrogen collection, simultaneously. Each of these modalities yield valuable information pertaining to the ongoing corrosion process. Combining them can yield holistic information on the role of microstructure, processing history, presence of coatings, etc., on the sequence of steps occurring during the corrosion process, and how they correlate with the acquired electrochemical data. Four materials systems, namely AA6061-T6 aluminum alloy, AZ91 magnesium alloy, galvanized DP590 steel, and pure Zn, were investigated under open circuit potential and under potentiodynamic polarization. The multimodal corrosion system was utilized to observe processes such as surface passivation and dissolution, pit and filiform corrosion initiation and propagation, and was correlated with location and magnitude of hydrogen evolution. This approach is shown to yield a truly multimodal understanding of the ongoing corrosion processes.

走査型電気化学セルインピーダンス顕微鏡(SECCIM)を用いたMg合金と鋼の接合界面における電気化学的腐食の調査 Investigating electrochemical corrosion at Mg alloy-steel joint interface using scanning electrochemical cell impedance microscopy (SECCIM)

Venkateshkumar Prabhakaran,Lyndi Strange,Rajib Kalsar,Olga A. Marina,Piyush Upadhyay &Vineet V. Joshi

Scientific Reports Published:15 August 2023

DOI:https://doi.org/10.1038/s41598-023-39961-2

Abstract

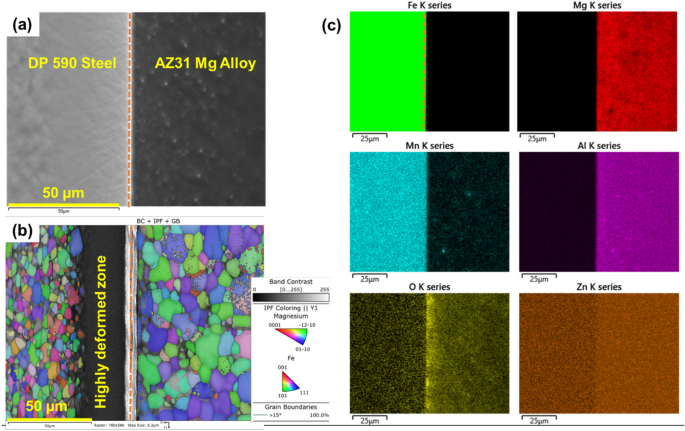

Developing strategies to prevent corrosion at the interface of dissimilar metal alloys is challenging because of the presence of heterogenous distribution of galvanic couples and microstructural features that significantly change the corrosion rate. Devising strategies to mitigate this interfacial corrosion requires quantitative and correlative understanding of its surface electrochemical reaction. In this work, scanning electrochemical cell impedance microscopy (SECCIM) was employed to study location-specific corrosion in the interfacial region of dissimilar alloys, such as AZ31 (magnesium alloy) and DP590 (steel) welded using the Friction-stir Assisted Scribe Technique (FAST) processes. Herein, SECCM and SECCIM were used to perform correlative mapping of the local electrochemical impedance spectroscopic and potentiodynamic polarization to measure the effect of electronic and microstructural changes in the welded interfacial region on corrosion kinetics. Microstructural characterization including scanning electron microscopy and electron backscatter diffraction was performed to correlate changes in microstructural features and chemistry with the corresponding electronic properties that affect corrosion behavior. The variations in corrosion potential, corrosion current density, and electrochemical impedance spectroscopy behavior across the interface provide deeper insights on the interfacial region—which is chemically and microstructurally distinct from both bare AZ31 and DP590 that can help prevent corrosion in dissimilar metal structures.

走査型電気化学セルインピーダンス顕微鏡(SECCIM)を用いた金属表面の局所腐食の理解 Understanding Localized Corrosion on Metal Surfaces Using Scanning Electrochemical Cell Impedance Microscopy (SECCIM)

Venkateshkumar Prabhakaran, Rajib Kalsar, Lyndi Strange, Olga A. Marina, Ramprashad Prabhakaran, and Vineet V. Joshi

The Journal of Physical Chemistry Published:July 26, 2022

DOI:https://doi.org/10.1021/acs.jpcc.2c03807

Abstract

Understanding the electrochemical properties at a localized scale is critically important to comprehend the origin of corrosion and develop multifunctional materials with robust corrosion resistance, particularly at conjoined metal interfaces typically encountered in automobile manufacturing. Scanning electrochemical cell microscopy (SECCM) is an emerging technique which enables to study the corrosion of metal surfaces to be visualized at the microscopic level. In this work, we developed scanning electrochemical cell impedance microscopy (SECCIM) by combining SECCM with electrochemical impedance spectroscopy (EIS) and explored the unique advantages of using SECCIM to measure the corrosion kinetics on single-crystal Mg (0001) as the model surface using direct current and alternating current polarization techniques. Specifically, a theta capillary with a tip diameter of 10 μm filled with a 0.01 M NaCl electrolyte was used as a probe to perform spatially resolved potentiodynamic Tafel polarization and EIS. The combination of traditional SECCM with EIS led to the development of SECCIM and enabled us to study small interfacial events such as charge transfer, adsorption, and emergence of resistive oxide films on the surface using the distribution of relaxation time analysis. Furthermore, by comparing localized SECCIM measurements with bulk electrochemical measurements, we establish the reliability of SECCIM for the mapping of corrosion potential and associated charge-transfer resistance on the Mg (0001) surface. Our results indicate that SECCIM measurement with Tafel and EIS analysis will provide an unparalleled ability to characterize the pitting corrosion mechanism on the heterogeneous surface of mixed-metal alloys and metal joints.