不要なリンゴを木から手際よく取り除く「エンドエフェクター」試作 Prototype ‘end-effector’ capable of deftly removing unwanted apples from trees

2022-07-18 ペンシルベニア州立大学(PennState)

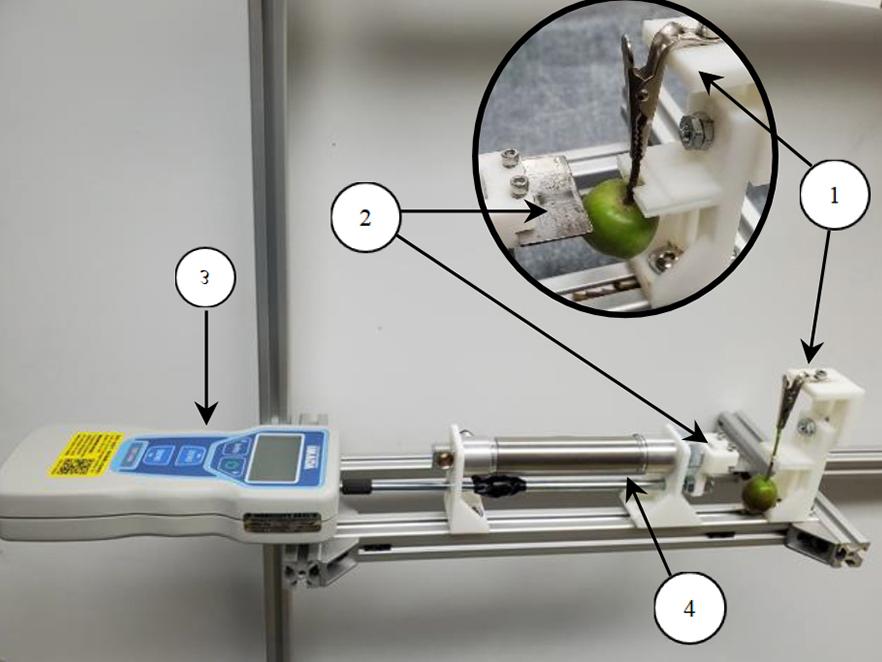

The set-up for measurement of green fruit removal forces for stem cutting included a stem-holding mount (1), stem- cutting blade (2), digital force gauge (3) and force-transfer rod (4). Credit: Penn State. Creative Commons

The set-up for measurement of green fruit removal forces for stem cutting included a stem-holding mount (1), stem- cutting blade (2), digital force gauge (3) and force-transfer rod (4). Credit: Penn State. Creative Commons

エンドエフェクターとプロトタイプを用いたすべての実験で、青果物の除去の成功率は90%以上であった。

エンドエフェクターとロボットマニピュレーターを連動させることで、さまざまな位置や方向で果実を除去できるロボット青果システムの可能性が示されました。ロボットによる青果物の間引きは、手作業による間引きと同等の選択性を持つ可能性があると、研究者は示唆した。

<関連情報>

- https://www.psu.edu/news/research/story/agricultural-engineers-design-early-step-robotic-green-fruit-thinning/

- https://elibrary.asabe.org/abstract.asp

青果物間引きロボット用エンドエフェクタ開発のための青果物除去ダイナミクス Green Fruit Removal Dynamics for Robotic Green Fruit Thinning End-Effector Development

Magni Hussain, Long He, James Schupp, Paul Heinemann

the American Society of Agricultural and Biological Engineers 2022

doi: 10.13031/ja.14974

Highlights

Pulling and stem-cutting methods were used for measuring the green-fruit removal dynamics.

A stem-cutting end-effector prototype was designed, developed, and tested for green fruit removal.

No significant correlation was found between fruit/stem size and the required force for fruit removal.

The success rate of the stem-cutting end-effector prototype for all experiments was over 90%.

Abstract

Green fruit thinning is one of the most important operations in apple production for obtaining high-quality fruit. Manual thinning is time-intensive, making it impractical for large acreages. Some alternative methods such as chemical and mechanical thinning have greatly improved work efficiency, while both have drawbacks due to non-selective targeting. Robotic green fruit thinning can potentially be as selective as manual thinning. This study developed an effective end-effector for robotic green fruit thinning. Prior to designing the end-effector, a series of fruit removal dynamics tests were conducted to find the forces required for robotic thinning using pulling or stem cutting methods on three different apple cultivars. The overall pulling detachment mean forces were 24.78±0.48 and 19.91±0.55 N when detaching stem from the fruit-end and the spur-end respectively. The average force required for stem cutting was 33.6±8.0 N among the three cultivars. There were no significant differences found between fruit/stem dimensions and the forces required for removal. A stem-cutting end-effector prototype was then developed to conduct fruit removal experiments in field conditions. Two end-effector prototype settings were tested, with one placing the end-effector onto a handheld bar, and the other integrating the end-effector with a six DoF robotic manipulator. The success rates of green fruit removal for all end-effector prototype experiments were over 90%. The end-effector is a core component in an automated green fruit thinning system. Integration with the robotic manipulator also indicated the potential of a robotic green fruit system to remove fruit at different locations and orientations. A machine vision system will be developed and integrated with the end-effector to develop a robotic green fruit thinning system.