ペンシルベニア州立大学の研究者が「ライジングスター」に認定される Penn State researcher was recognized as ‘Rising Star’ for the work

2022-08-24 ペンシルベニア州立大学(PennState)

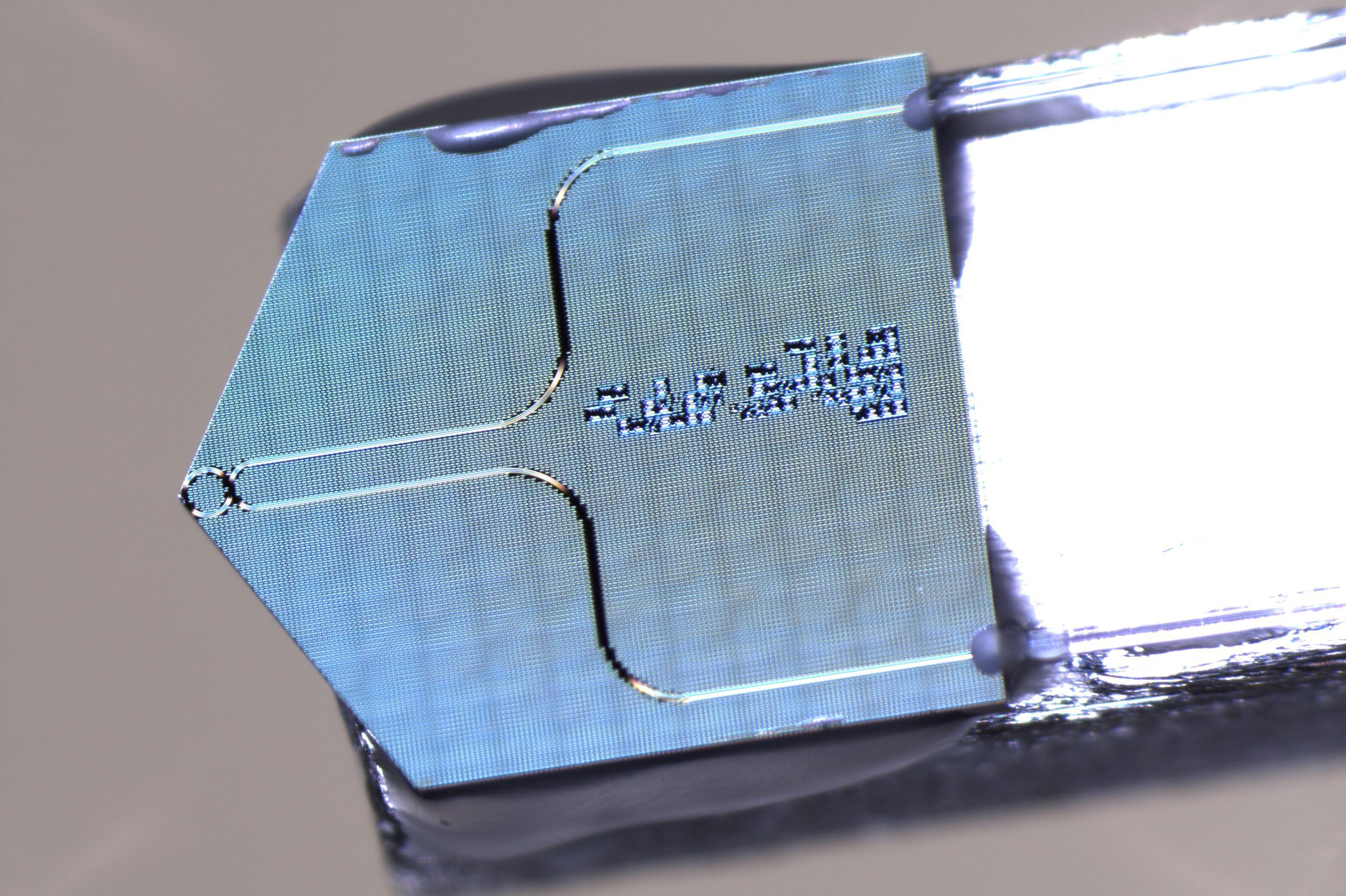

Penn State researchers developed a new nanoengineered granular hydrogel bioink, used here to print an image of the Nittany Lion logo. This bioink helps to achieve previously unattained levels of porosity, shape fidelity and cell integration when 3D printing biomaterials. Credit: Provided by Amir Sheikhi. All Rights Reserved.

Penn State researchers developed a new nanoengineered granular hydrogel bioink, used here to print an image of the Nittany Lion logo. This bioink helps to achieve previously unattained levels of porosity, shape fidelity and cell integration when 3D printing biomaterials. Credit: Provided by Amir Sheikhi. All Rights Reserved.

自己組織化するナノ粒子を用いてマイクロゲルを可逆的に結合させることにより、粒状ハイドロゲルの3Dバイオプリントのこれまでの限界を克服しました。これにより、微細孔がよく保存され、印刷適性と形状の忠実性が向上した粒状ハイドロゲルバイオインクの作製が可能になった。”

マイクロゲル同士の粘着性を高めることで、粒状ハイドロゲルの優れた特性を維持したまま、「ジャミング」の問題に対処した。マイクロゲルは互いにくっつき、マイクロゲルに吸着したナノ粒子の界面自己組織化の結果、密な充填の必要性がなくなり、ミクロスケールの孔が保たれるのである。

<関連情報>

- https://www.psu.edu/news/engineering/story/new-granular-hydrogel-bioink-could-expand-possibilities-tissue-bioprinting/

- https://onlinelibrary.wiley.com/doi/10.1002/smll.202202390

バイオプリンティングのための微細孔を有するナノグラニュラーハイドロゲルバイオリンクの開発 Nanoengineered Granular Hydrogel Bioinks with Preserved Interconnected Microporosity for Extrusion Bioprinting

Zaman Ataie,Sina Kheirabadi,Jenna Wanjing Zhang,Alexander Kedzierski,Carter Petrosky,Rhea Jiang,Christian Vollberg,Amir Sheikhi

Small Published: 03 August 2022

DOI:https://doi.org/10.1002/smll.202202390

Abstract

3D bioprinting of granular hydrogels comprising discrete hydrogel microparticles (microgels) may overcome the intrinsic structural limitations of bulk (nanoporous) hydrogel bioinks, enabling the fabrication of modular thick tissue constructs. The additive manufacturing of granular scaffolds has predominantly relied on highly jammed microgels to render the particulate suspensions shear yielding and extrudable. This inevitably compromises void spaces between microgels (microporosity), defeating rapid cell penetration, facile metabolite and oxygen transfer, and cell viability. Here, this persistent bottleneck is overcome by programming microgels with reversible interfacial nanoparticle self-assembly, enabling the fabrication of nanoengineered granular bioinks (NGB) with well-preserved microporosity, enhanced printability, and shape fidelity. The microporous architecture of bioprinted NGB constructs permits immediate post-printing 3D cell seeding, which may expand the library of bioinks via circumventing the necessity of bioorthogonality for cell-laden scaffold formation. This work opens new opportunities for the 3D bioprinting of tissue engineering microporous scaffolds beyond the traditional biofabrication window.

オリエンタルエアブリッジ所属 ボンバルディアDHC-8-402の事故[着陸時のテールストライク(胴体後部下面接触)損傷](福江空港、令和2年10月23日)](https://tiisys.com/wp-content/uploads/2022/08/orientaru-500x191.png)