2022-02-03 オーストラリア連邦研究会議(ARC),Researchers Dr Jianbo Tang and Prof Kourosh Kalantar-zadeh at UNSW

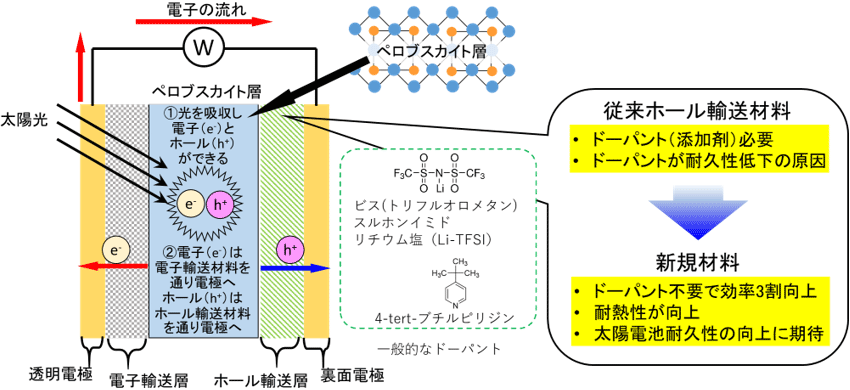

研究チームは、ガリウム(Ga)などの低融点溶媒に銀(Ag)などの金属を少量溶かし、金属液体混合物(合金)が凝固する際に、金属成分がどのように相互作用し分離してパターンが形成されるかを調査した。

その結果、銀とガリウムの単一系で、Ag2Ga化合物の粒子や束状の構造など、明確なパターンを形成できることがわかった。

“The long divided, must unite; long united, must divide. Thus it has ever been.”

The opening lines of the great Chinese historical novel Romance of the Three Kingdoms condense its complex and spectacular stories into a coherent pattern, that is, power blocs divide and unite cyclically in turbulent battle years.

A good philosophy or theorem has general implications. Now, published in the journal Nature Synthesis, scientists from Australia, New Zealand, and the US reported a new type of solidification patterns that resembles the plots in the Chinese classic, but this time appearing on the surface of solidifying liquid metals.

The team dissolved a small amount of metals such as silver (Ag) in low-melting-point solvent metals such as gallium (Ga), and investigated how the metallic components interact and separate to form patterns when the metallic liquid mixtures (alloys) solidify.

The researchers found that a single silver–gallium system can produce distinct patterns such as particles or bundle-like structures of a Ag2Ga compound.

Surface pattern formation during solidification of a Ag-Ga alloy (optical microscope)

The individual Ag2Ga structures that build the patterns are small, with micrometre or nanometre thicknesses, tens or hundreds of times less than a human hair.

Most surprisingly, the researchers observed that the patterns divide and unite in a repeated manner. “The first time I saw such cyclic divergent-convergent patterns, it immediately reminded me of the famous opening lines of the Romance of the Three Kingdoms,” said Dr Jianbo Tang from University of New South Wales (UNSW, Australia), who is the first author of the study.

Pattern formation is a fundamental yet ubiquitous phenomenon which has interested and inspired scientists for a long time. Some pattern types are more common than others.

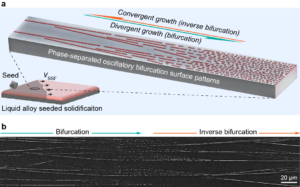

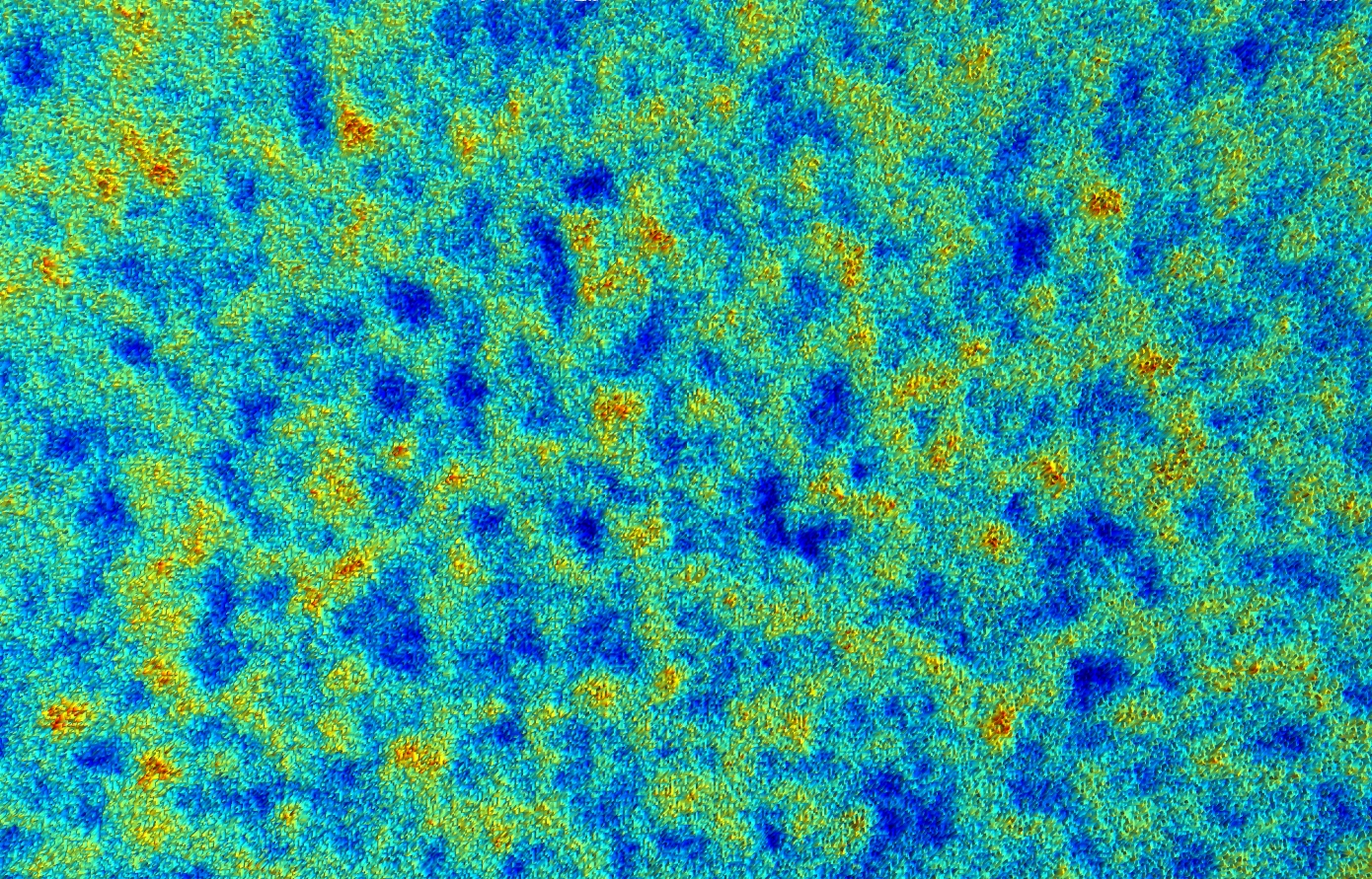

Top: Divergent surface patterning spreading out from a ‘seed’ (left to right), meeting convergent patterning (right to left). Bottom: oscillatory bifurcation patterns on surface of solidified Ag-Ga alloy (scanning electron microscopy image)

Among all the diverse patterning behaviours, divergent pattern formation, or bifurcation, is frequently seen in nature because this particular arrangement generally favours energy conversion or distribution. “I.e. it’s the ‘easiest’ path,” explains Dr Tang. River networks, tree branches, lightning pathways, and vascular systems are all examples of bifurcation.

In comparison, convergent pattern growth, or inverse bifurcation, is encountered less frequently as it is contrary to the energetically favourable bifurcation.

The strange cyclic divergent and convergent growth, called oscillatory bifurcation, is rare and has not been observed in solidification structures prior to the new published work.

Despite this, the researchers observed oscillatory bifurcation patterns on the surface of several liquid alloys after solidification, which suggests that this counter-intuitive behaviour is quite general for solidification patterns forming on the surface of liquid metals.

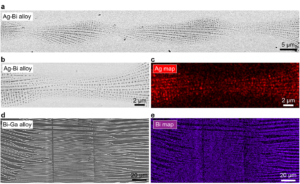

Examples of oscillatory bifurcation patterns observed in (a-c) Ag-Bi alloys and (d,e) Bi-Ga alloys. Scanning electron microscopy (a,b,d) and energy dispersive spectroscopy (c,e)

Analogous to the dramatized novel where the turbulent forces between and within a large number of power blocs drive those groups to divide and unite, the team found that it is also the instability of the liquid metal surface that underlies the emergence of the exotic oscillatory bifurcation patterns.

“Surface pattern formation of liquid metal alloys is a new but exciting topic. The surface or interfacial nature of the process enables us to better understand and control fundamental phase transition and pattern formation.” Dr. Tang added, “We will continue our work on designing crystalline surface patterns and structures using liquid metals to enable cutting-edge applications such as plasmonic sensing, high-efficiency electronics and optics, and high-precision spectroscopy.”

THE STUDY

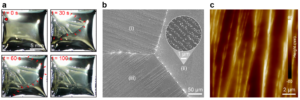

Left: Time-lapse of the seeded surface solidification process, with arrows indicating the propagating direction of the surface solidification front. Centre: scanning electron microscopy reveals multiple surface subdomains with different patterns. Right: atomic force microscopy of the surface patterns.

Experimentation was conducted at the Centre for Advanced Solid and Liquid based Electronics and Optics (CASLEO) based at UNSW, led by CASLEO Director Prof Kourosh Kalantar-Zadeh.

Two molecular dynamics simulation groups, one led by Prof Salvy Russo (RMIT University, Australia) and the other by Prof Nicola Gaston (MacDiarmid Institute for Advanced Materials and Nanotechnology and University of Auckland, New Zealand), carried out supercomputer simulations to provide atomistic insights to the phenomenon. The collaboration with Prof Gaston’s group was established through the Australian Research Council Centre of Excellence in Future Low-Energy Electronics Technologies (FLEET).

As well as bringing together FLEET researchers from two participating nodes (UNSW and RMIT) and one partner organisation (MacDiarmid), the work combined two ARC Centres of Excellence: FLEET, and the Centre for Exciton Science.

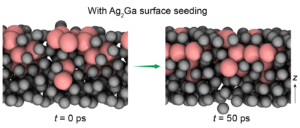

Initial and final (50 picoseconds) atomic configurations of the Ag atoms (pink) and Ga atoms (grey) seen in one of the molecular dynamics simulations

Oscillatory bifurcation patterns initiated by seeded surface solidification of liquid metals was published in Nature Synthesis February 2022. DOI: 10.1038/s44160-021-00020-1

Authors: Jianbo Tang, Stephanie Lambie, Nastaran Meftahi, Andrew J. Christofferson, Jiong Yang, Jialuo Han, Md. Arifur Rahim, Mohannad Mayyas, Mohammad B. Ghasemian, Francois-Marie Allioux, Zhenbang Cao, Torben Daeneke, Chris F. McConville, Krista G. Steenbergen, Richard B. Kaner, Salvy P. Russo, Nicola Gaston and Kourosh Kalantar-Zadeh.

In addition to support from the Australian Research Council (Laureate Fellowship, Centres of Excellence, and Discovery programs) this work was also supported by computational resources provided by the Australian Government through the National Computational Infrastructure facility and the Pawsey Supercomputer Centre.