2025-07-03 東北大学

<関連情報>

- https://www.tohoku.ac.jp/japanese/2025/07/press20250703-01-catalyst.html

- https://www.tohoku.ac.jp/japanese/newimg/pressimg/tohokuuniv-press20250703_01_catalyst.pdf

- https://www.sciencedirect.com/science/article/pii/S0378775325016209

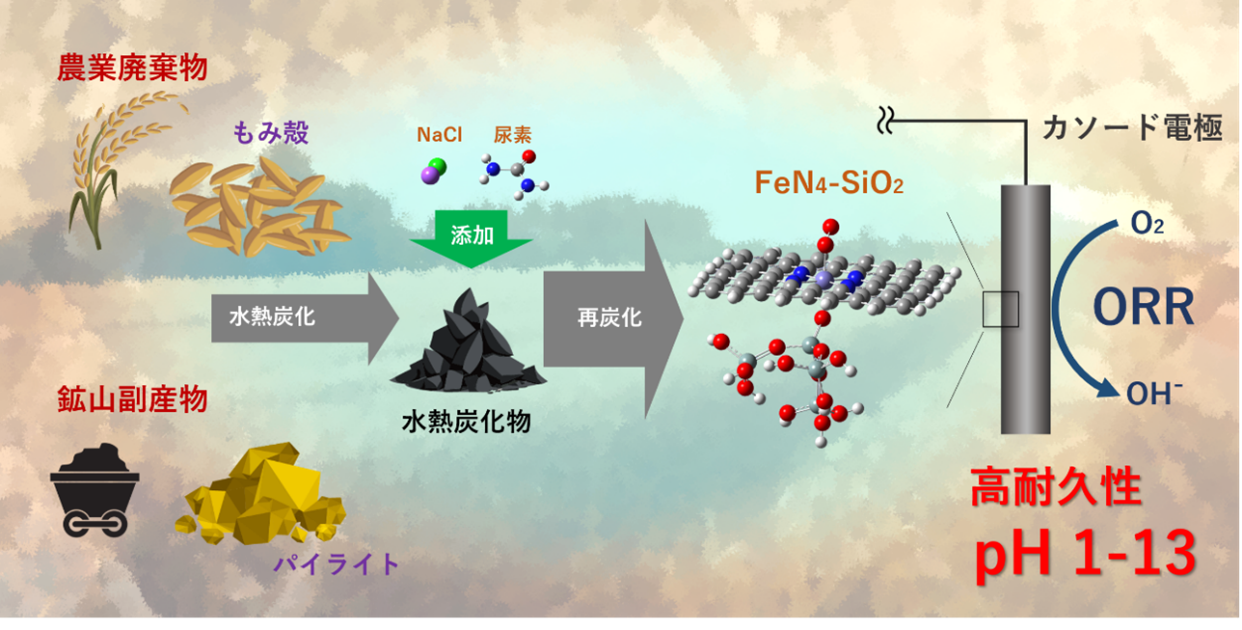

酸性からアルカリ性媒体での酸素還元反応のための、未使用天然資源からの高活性かつ安定したFe-N 4触媒 Highly active and stable Fe-N4 catalyst from unused natural resources for oxygen reduction reaction in acidic to alkaline medium

Edwin Osebe Nyangau, Hiroya Abe, Kazutoshi Haga, Chie Ooka, Kenji Hayashida, Naoka Nagamura, Kotaro Takeyasu, Masaru Watanabe, Yuta Nakayasu

Journal of Power Sources Available online: 30 June 2025

DOI:https://doi.org/10.1016/j.jpowsour.2025.237784

Highlights

- Fe–N4 site stabilization gives 17 % higher stability than Pt/C in acidic media.

- Catalyst synthesized from rice husks and mining waste for ORR applications.

- Unique fifth coordination forms between Fe–N4 and amorphous SiO2 from rice husks.

- Delivers 160 mW cm−2 in Zn–air batteries, outperforming Pt/C at 120 mW cm−2.

Abstract

Iron–nitrogen–carbon (Fe–N–C) catalysts with Fe–N4 coordination are promising alternatives to platinum-based materials for the oxygen reduction reaction (ORR), yet their instability in acidic media limits practical applications. Herein, we report a sustainable Fe–N–C catalyst (RH-Fe-N) synthesized from rice husks and pyrite, serving as carbon and iron sources, respectively. This approach eliminates the need for complex precursors such as metal–organic frameworks, using a simple three-step carbonization method including hydrothermal carbonization. The resulting catalyst incorporates Fe atoms into a carbon matrix with self-doped amorphous SiO2 from rice husks. Spectroscopic and theoretical analysis reveals a unique fifth Fe–O coordination within the SiO2 matrix, enhancing site stability and ORR activity. In Zn–air battery applications, RH-Fe-N achieves a peak power density of 160 mW cm−2, outperforming commercial Pt/C (40 wt%) at 120 mW cm−2, with a higher open-circuit voltage (1.50 V vs. 1.40 V for Pt/C). The catalyst also demonstrates superior durability, with 17 % and 16 % higher stability than Pt/C in acidic and neutral conditions, respectively. This work provides a low-cost, scalable, and eco-friendly strategy for developing high-performance ORR catalysts across all pH ranges, contributing to sustainable energy generation and circular economy goals.