2025-04-29 中国科学院(CAS)

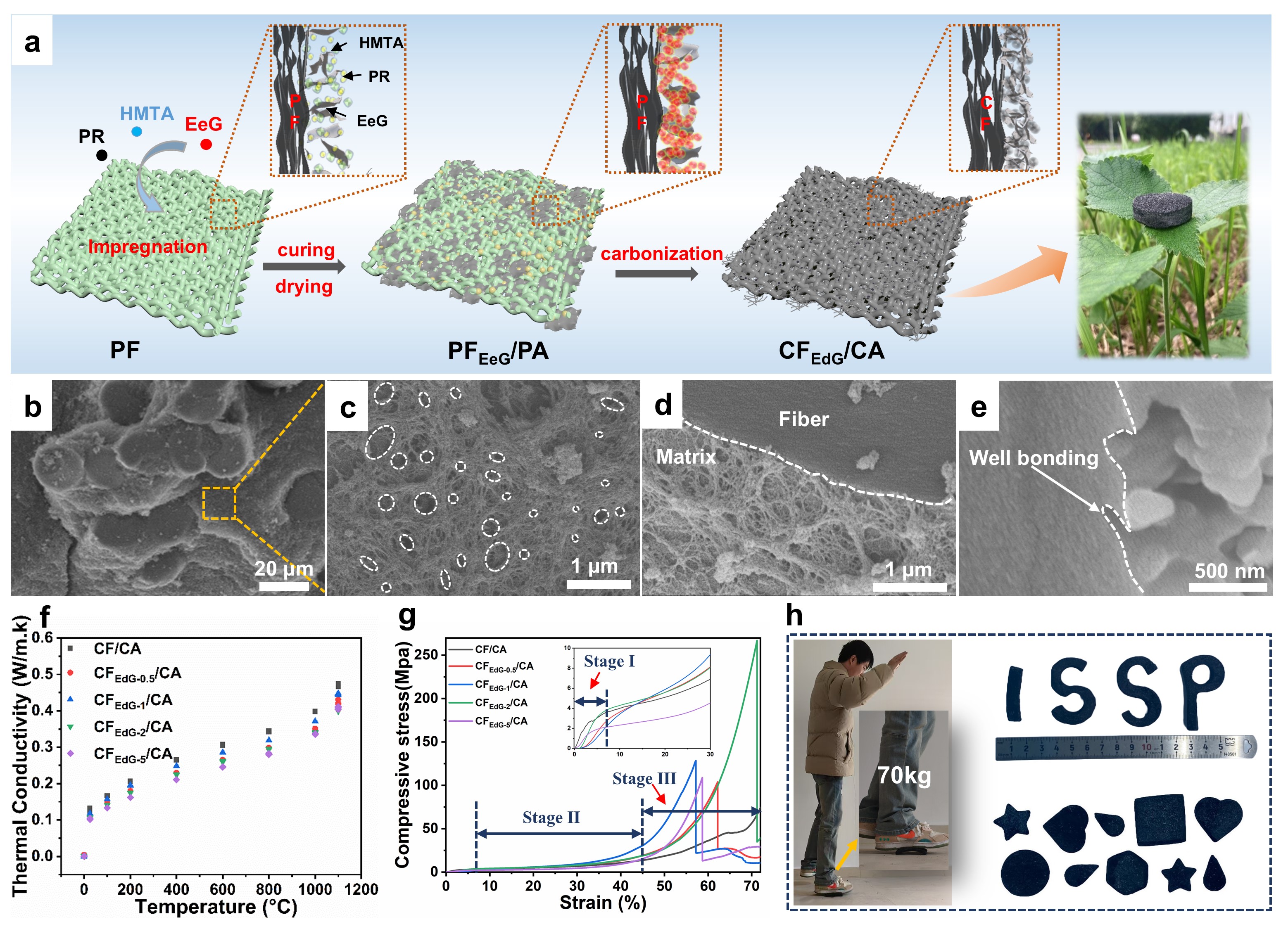

The synthesis schematic (a), microstructure characterization (b-e), thermal conductivities at different temperatures (f), stress-strain curves (g) and molding performance (h) of the carbon-based aerogel composites. (Image by YU Jie)

The synthesis schematic (a), microstructure characterization (b-e), thermal conductivities at different temperatures (f), stress-strain curves (g) and molding performance (h) of the carbon-based aerogel composites. (Image by YU Jie)

<関連情報>

- https://english.cas.cn/newsroom/research_news/phys/202504/t20250430_1042406.shtml

- https://www.sciencedirect.com/science/article/pii/S2238785425009524

- https://www.sciencedirect.com/science/article/abs/pii/S2468606925000607

高温断熱のための機械的および酸化防止特性を向上させた炭素繊維強化SiCエアロゲル複合材料の合成 Synthesis of carbon fiber reinforced SiC aerogel composites with enhanced mechanical and antioxidant properties for high temperature insulation

Chunxue Zheng, Jie Yu, Xinyang Li, Jingbo Duan, Zhulin Huang, Ming Li, Xiaoye Hu

Journal of Materials Research and Technology Available online: 14 April 2025

DOI:https://doi.org/10.1016/j.jmrt.2025.04.131

Abstract

High-temperature thermal-insulation aerogels with high mechanical strength and well oxidation resistance are critical for the thermal protect system (TPS) of aerospace vehicles. However, it is still challenging to achieve large-scale preparation of aerogels that integrate the above functions through a simple method. In this work, carbon fiber (CF) felts are introduced as a reinforcement and template to prepare silicon carbide nanowire (SiCnw) aerogel composites through a simple in-situ growth strategy. The high-strength CF as the skeleton endows high mechanical strength, and the in-situ grown SiCnw aerogels lead to good thermal insulation of the composites. More importantly, a dense SiC shell was also formed and tightly coated on the surface of CF (CF@SiC) during the in-situ growth process, which effectively protects the CF from oxidation, thus enhancing the high temperature oxidation resistance of the composites. As a result, the optimal CF@SiC/SiCnw aerogel composites possess a low thermal conductivity of only 0.056 W m−1 K−1 at room temperature. The back temperature of the 9 mm thick composites is only 151.9 °C after exposure to a butane flame at 1220 °C for 300 s, and it still maintains considerable thermal insulation and mechanical properties after the ablation. In addition, the machinability of the CF felts makes it easy to prepare the composites in various shapes and larger sizes. This work provides a simple and scalable strategy to synthesize reliable SiC-based aerogel composites for high-temperature thermal insulation applied in extreme environments.

極限環境下での断熱のための機械的特性を向上させた膨張性グラファイト最適化炭素繊維/炭素エアロゲル複合材料 Expandable graphite optimized carbon-fiber/carbon-aerogel composites with enhanced mechanical property for thermal insulation under extreme environments

Ningning Zhou, Qiaoqian Wang, Jie Yu, Xinyang Li, Ming Li, Dilong Liu, Xiaoye Hu, Zhulin Huang

Materialstoday Energy Available online: 24 February 2025

DOI:https://doi.org/10.1016/j.mtener.2025.101852

Highlights

- A multi-scale reinforced structure was successfully constructed through the incorporation of expandable graphite into the CF/CA composites.

- In-situ expansion of the expandable graphite effectively mitigates the carbonization shrinkage by 19 %, addressing a critical limitation in CF/CA composite processing.

- The optimized CFEdG/CA composites exhibit enhanced mechanical properties, with a maximum compressive strength of 226.9 MPa and an elastic modulus of 1935.2 MPa.

- The cost-effective CFEdG/CA composites also demonstrate a low thermal conductivity of 0.108 W m−1 K−1 at room temperature and 0.404 W m−1 K−1 at 1100 °C.

Abstract

The incorporation of high-strength carbon fibers (CF) effectively enhances the self-supporting ability of the carbon aerogels (CA), enabling the large-scale preparation of CF-reinforced CA (CF/CA). However, the carbonization shrinkage and structural mismatch between CF and CA severely restricts the mechanical and thermal-insulation properties of the CF/CA composites. Here, we proposed to introduce the expandable graphite (EG), which can expand up to tens of times its original volume at the feasible temperature, as a link and bonding material in the CF/CA composites. Thanks to the in-situ expansion of the EG during the carbonization process, the expanded graphite (EdG) optimized CF/CA composites show a 19 % reduction in carbonization shrinkage relative to the CF/CA composites, resulting in the thermal conductivity of 0.108 and 0.404 W m−1 K−1 at room temperature and 1100 °C, respectively. Moreover, as a consequence of the multi-scale reinforced structure and the well link and bonding role of the EdG, the maximum compressive strength of the CFEdG/CA composites reach 226.9 MPa, which is much higher than that of CF/CA composites (91.8 MPa), as well as most reported aerogel and its composites. This work provides a facile strategy to synergistically enhance the thermal insulation and mechanical properties of the CF/CA composites.