2025-04-24 ペンシルベニア州立大学(PennState)

<関連情報>

- https://www.psu.edu/news/engineering/story/cold-manufacturing-approach-make-next-gen-batteries

- https://www.sciencedirect.com/science/article/abs/pii/S2468606925000371

ポリマー・イン・セラミックス固体電解質の低温焼結制御界面および集積化のプロービング Probing cold sintering-regulated interfaces and integration of polymer-in-ceramic solid-state electrolytes

Bo Nie, Ta-Wei Wang, Seok Woo Lee, Juchen Zhang, Hongtao Sun

Materialstoday Energy Available online: 4 February 2025

DOI:https://doi.org/10.1016/j.mtener.2025.101829

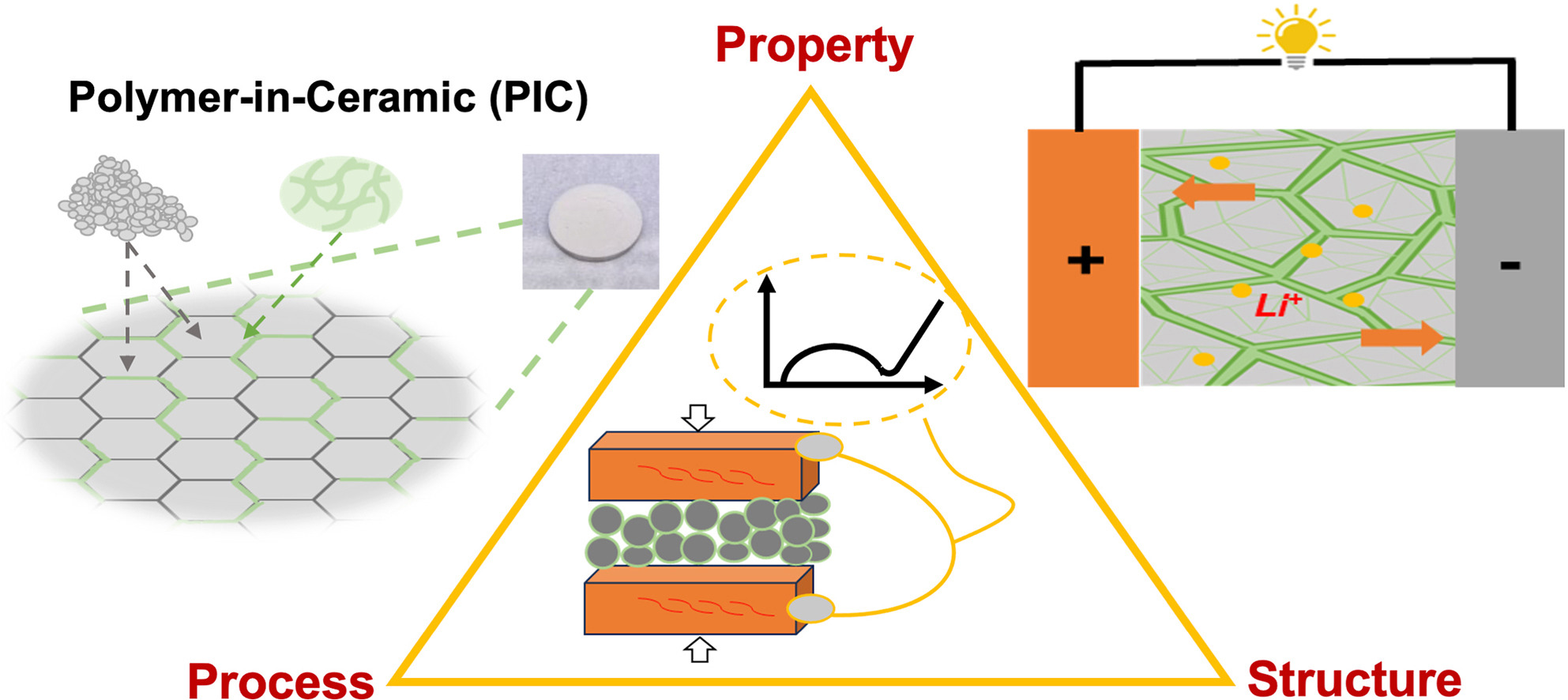

Graphical abstract

Highlights

- The cold sintering process (CSP) is used to densify the polymer-in-ceramic solid-state electrolytes.

- Optimize the solid-state electrolyte by regulating the process-structure-property correlation.

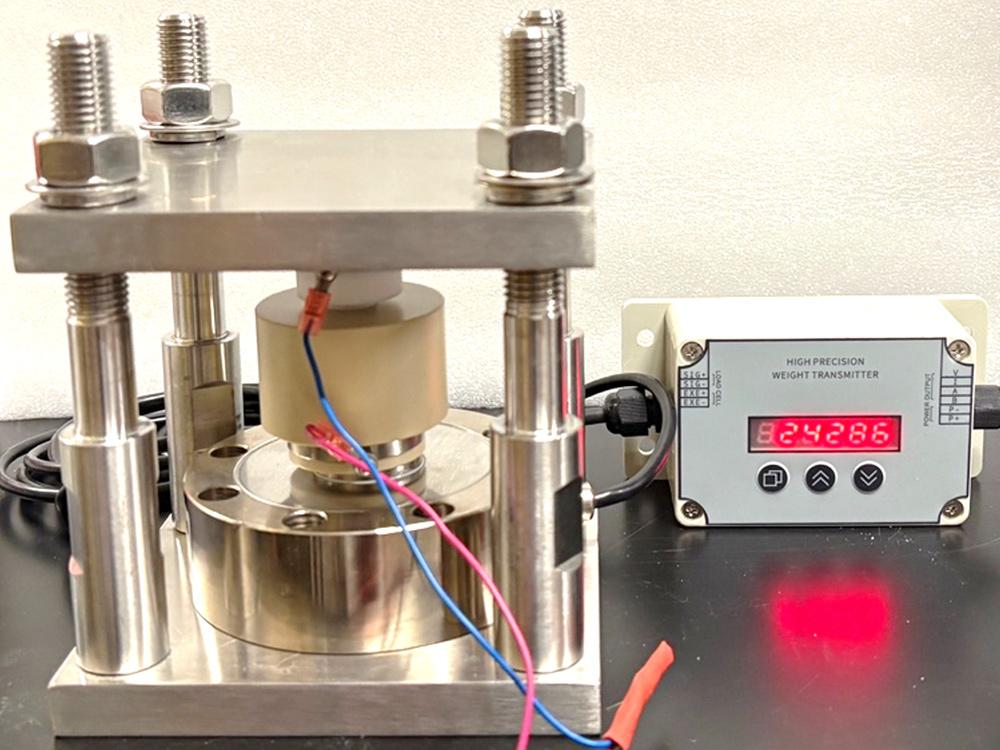

- In situ electrochemical impedance spectroscopy (EIS) to reveal densification and interface properties.

- The polymer-in-ceramic solid electrolyte exhibited high conductivity of 0.42 mS cm−1 at room temperature.

Abstract

Solid-state batteries (SSBs) are considered the next-generation energy storage technology, offering safer and more stable alternative to conventional Li-ion batteries with flammable liquid electrolytes. Among various solid-state electrolytes (SSEs), the NASICON-phase Li1.3Al0.3Ti1.7(PO4)3 (LATP) stands out as a promising candidate due to its high ionic conductivity at room temperature and excellent stability in air. However, densifying oxide-based LATP SSEs typically requires high-temperature sintering, while ion depletion across grain boundaries significantly limits the practical performance of SSBs. To overcome these challenges, we introduce a transient liquid-assisted cold sintering process (CSP) to seamlessly integrate dissimilar ionic conducting materials into polymer-in-ceramic (PIC) composite SSEs under pressure and mild heating. This process enables the uniform distribution of a highly conductive poly(ionic liquid) gel (PILG) phase at the boundaries of LATP particles, effectively reducing interfacial resistance. In-situ electrochemical impedance spectroscopy (EIS) was employed to monitor real-time impedance changes during densification process, providing insights into dynamic interface behaviors. The LATP-PILG composite SSE achieved high ionic conductivities of 4.2 × 10−4 S cm−1 and 5.15 × 10−4 S cm−1 in a coin cell and a split cell under 20 MPa at room temperature, respectively. Furthermore, it demonstrated reversible plating/stripping for hundreds of hours. The integrated LiFePO4-PILG||LATP-PILG|PILG||Li cell exhibited excellent cycling stability.