2024-05-14 ノースカロライナ州立大学(NCState)

<関連情報>

- https://news.ncsu.edu/2024/05/faster-finishing-for-3d-printed-parts/

- https://www.inderscience.com/info/inarticle.php?artid=138337

重要な公差を持つ付加製造部品の自動フィーチャーベース検査と認定 Automatic feature-based inspection and qualification for additively manufactured parts with critical tolerances

Christopher J. Kelly; Richard A. Wysk; Ola A. Harrysson; Russell E. King; Brandon M. McConnell

Journal of Manufacturing Technology and Management Published:01 May 2024

DOI:https://dx.doi.org/10.1504/IJMTM.2024.138337

Abstract

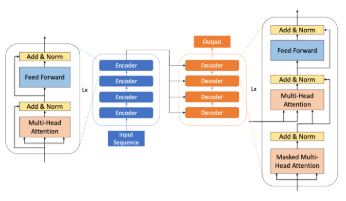

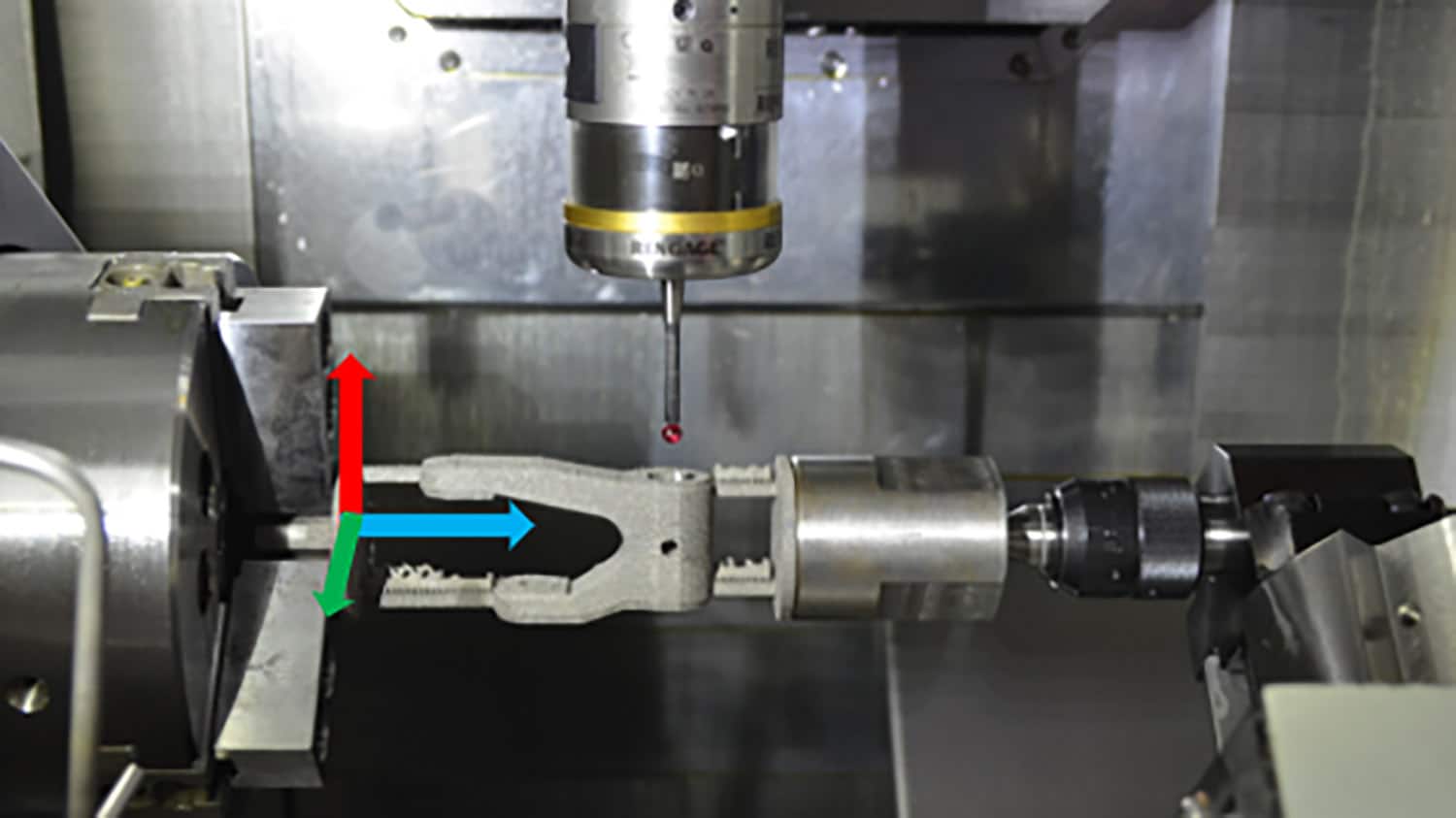

This work expands the capabilities of the digital additive and subtractive hybrid (DASH) system by including geometric qualification of mechanical products. Specifically, this research incorporates the extended additive manufacturing format files (AMF-TOL) which include American Society of Mechanical Engineers (ASME) Y14.5 specifications for planes, cylinders and other features so that in-process inspection can be completed automatically. An example for the production of holes is provided to illustrate on-machine-measurement collects sample radii to estimate the size and position of finished cylindrical features. Statistical analysis was used to measure bounds for comparison to specified tolerance callouts to determine whether a part is within specification, within a user-defined level of confidence. Seven different sampling strategies were evaluated on a DASH part including the bird cage sampling strategy defined in ISO-12180. Part data was utilised to show that for large data samples no statistically significant difference in accuracy was identified for four methods. Finally, analysis shows that using the DASH process with automatic inspection is economically advantageous for low volume production runs.