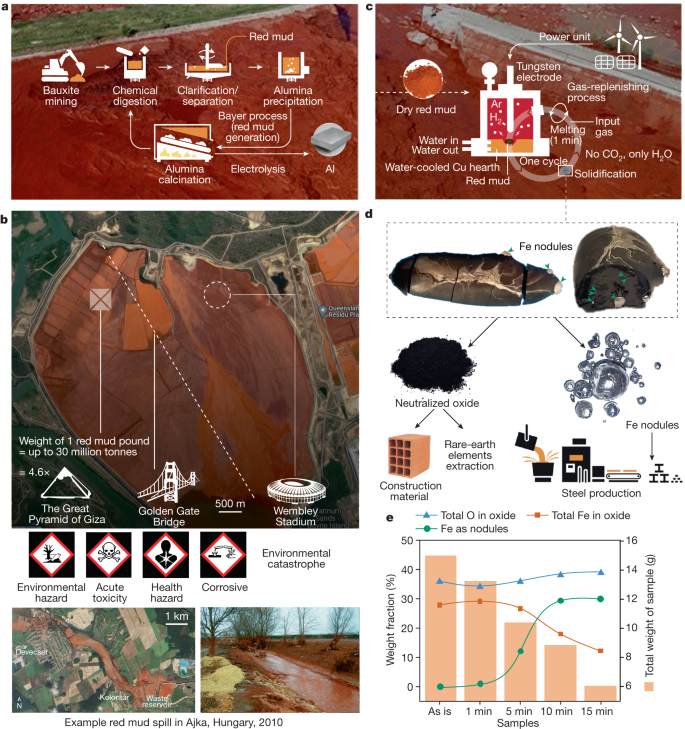

グリーン水素を用いた経済的なプロセスにより、アルミニウム製造時に発生する赤泥からCO2を含まない鉄を抽出することができる An economical process with green hydrogen can be used to extract CO2-free iron from the red mud generated in aluminium production

2024-01-30 マックス・プランク研究所

<関連情報>

- https://www.mpg.de/21476840/toxic-red-mud-aluminium-green-steel-industry

- https://www.nature.com/articles/s41586-023-06901-z

気候変動に左右されない水素プラズマ還元で赤泥からグリーン・スティールを作る Green steel from red mud through climate-neutral hydrogen plasma reduction

Matic Jovičević-Klug,Isnaldi R. Souza Filho,Hauke Springer,Christian Adam & Dierk Raabe

Nature Published:24 January 2024

DOI:https://doi.org/10.1038/s41586-023-06901-z

Abstract

Red mud is the waste of bauxite refinement into alumina, the feedstock for aluminium production1. With about 180 million tonnes produced per year1, red mud has amassed to one of the largest environmentally hazardous waste products, with the staggering amount of 4 billion tonnes accumulated on a global scale1. Here we present how this red mud can be turned into valuable and sustainable feedstock for ironmaking using fossil-free hydrogen-plasma-based reduction, thus mitigating a part of the steel-related carbon dioxide emissions by making it available for the production of several hundred million tonnes of green steel. The process proceeds through rapid liquid-state reduction, chemical partitioning, as well as density-driven and viscosity-driven separation between metal and oxides. We show the underlying chemical reactions, pH-neutralization processes and phase transformations during this surprisingly simple and fast reduction method. The approach establishes a sustainable toxic-waste treatment from aluminium production through using red mud as feedstock to mitigate greenhouse gas emissions from steelmaking.