2023-07-20 ピッツバーグ大学

◆ピッツバーグ大学の研究者たちは、海洋二酸化炭素捕捉の新たな解決策を開発している。海水と溶媒を接触させる膜コンタクターを使用して、二酸化炭素を海洋から除去する実験を行った。この方法では、海洋のpHを下げることで二酸化炭素を海水から分離し、再循環させることでコストを削減することが考えられている。現在、海水pHの変化を誘導する方法や直接海洋捕捉と淡水化を組み合わせることでシステムコストを下げる方法について研究が進められている。

<関連情報>

- https://news.engineering.pitt.edu/using-our-oceans-to-fight-climate-change/

- https://www.sciencedirect.com/science/article/abs/pii/S1385894723028711?via%3Dihub

- https://www.sciencedirect.com/science/article/abs/pii/S1385894723025998?via%3Dihub

カプセル化溶媒を用いた海洋での直接炭素回収の実証 Demonstration of direct ocean carbon capture using encapsulated solvents

Austin Lieber, Marina Hildebrandt, Shanna-Leigh Davidson, Joanna Rivero, Huda Usman, Tagbo H.R. Niepa, Katherine Hornbostel

Chemical Engineering Journal Available online: 22 June 2023

DOI:https://doi.org/10.1016/j.cej.2023.144140

Abstract

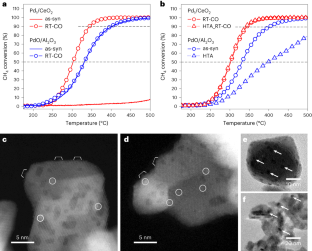

Direct ocean carbon capture (DOC) is an emerging form of negative emissions technology that requires expedited characterization and comparison against more well-established forms of carbon capture. Using microencapsulated solvents for DOC affords large membrane surface areas for carbon dioxide (CO2) in the ocean water to flux across a gas-permeable membrane, and reversible regeneration of the contained solution. The feasibility of using a packed bed of Na2CO3 capsules to extract CO2 from seawater is assessed here through lab-scale experimentation, one-dimensional modeling, and techno-economic assessment (TEA). The experimental flux measurements match the flux predictions of the 1D model, validating the model. Parametric studies with our capsule bed model suggest that for a balance between pressure drop and breakthrough time the optimal capsule diameter is between 400-600μm, the optimal bed porosity is between 0.5-0.7, and the optimal seawater velocity through the bed is 0.10-0.15 m/s. The TEA estimates that the carbon capture cost of a 1 MTonne/year greenfield system using Na2CO3 capsules would be exorbitant: $8,977.14 per tonne of CO2. This work demonstrates the potential of using microencapsulated solvents for direct ocean carbon capture and illustrates a need for further research to reduce system costs.

中空糸膜コンタクターによる海洋炭素直接回収の実証 Demonstration of direct ocean carbon capture using hollow fiber membrane contactors

Joanna Rivero, Austin Lieber, Christopher Snodgrass, Zöe Neal, Marina Hildebrandt, William Gamble, Katherine Hornbostel

Chemical Engineering Journal Available online :7 June 2023

DOI:https://doi.org/10.1016/j.cej.2023.143868

Abstract

The focus of membrane carbon capture to date has been primarily on point source capture, such as power plants and industrial capture. However, membrane technology can also play a role in negative emissions technology, such as direct air capture and direct ocean capture. Direct ocean capture has a few potential advantages over direct air capture, such as avoiding land use and coupling with offshore wind and offshore storage. The use and feasibility of hollow fiber membrane contactors (HFMCs) for direct ocean carbon capture with benign aqueous basic carbon dioxide solvents is assessed here through a multifaceted approach. A 1D HFMC model incorporates fluid dynamics and the chemical kinetics of both ocean water and aqueous sodium hydroxide solvent in order to simulate CO2 flux behavior in two flow configurations. Lab scale experiments of this system then guide a model refinement and validation process until experimental behaviors are predicted through computation. A preliminary technoeconomic assessment then uses computational and experimental results to estimate the carbon capture cost when the system is scaled to remove 0.98 Mtonnes CO2/year. Computational results suggest that higher seawater flow rates and temperatures relative to the sodium hydroxide solvent improve CO2 flux. The technoeconomic assessment suggests that HFMCs may only be cost-competitive if seawater pH is decreased at the membrane interface, thereby increasing the local concentration of dissolved carbon dioxide. These findings indicate that local pH swing on the seawater side will be necessary to feasibly remove carbon dioxide from seawater using HFMCs.