コロンビア工学部とファッション工科大学の研究者がタッグを組み、微生物の力と土着科学にヒントを得て、無害なバイオレザーを開発しました。 Researchers at Columbia Engineering and the Fashion Institute of Technology team up to create a non-toxic bioleather, inspired by the power of microbes and indigenous science.

2022-09-30 コロンビア大学

ナノセルロースを植物由来のレシチンでなめすという、環境にやさしいプロセスを開発し、強度が高く、堆肥化可能なバイオレザーを実現した。

<関連情報>

- https://www.engineering.columbia.edu/news/compostable-bioleather-offers-sustainable-solutions-clothing-industry-and-beyond

- https://pubs.rsc.org/en/content/articlelanding/2022/VA/D2VA00050D

循環型材料経済のための微生物由来ナノセルロースバイオテキスタイル Microbial nanocellulose biotextiles for a circular materials economy

Theanne N. Schiros, Romare Antrobus, Delfina Farías, Yueh-Ting Chiu, Christian Tay Joseph, Shanece Esdaille, Gwen Karen Sanchirico, Grace Miquelon, Dong An, Sebastian T. Russell, Adrian M. Chitu, Susanne Goetz, Anne Marika Verploegh Chassé, Colin Nuckolls, Sanat K. Kumar and Helen H. Lu

Environmental Science: Advances Published:27 May 2022

DOI:https://doi.org/10.1039/D2VA00050D

Abstract

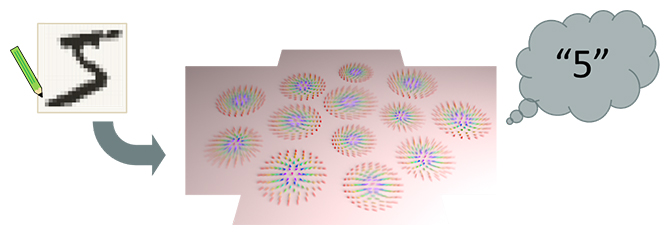

The synthesis and bottom-up assembly of nanocellulose by microbes offers unique advantages to tune and meet key design criteria—rapid renewability, low toxicity, scalability, performance, and degradability—for multi-functional, circular economy textiles. However, development of green processing methods that meet these criteria remains a major research challenge. Here, we harness microbial biofabrication of nanocellulose and draw inspiration from ancient textile techniques to engineer sustainable biotextiles with a circular life cycle. The unique molecular self-organization of microbial nanocellulose (MC) combined with bio-phosphorylation with a lecithin treatment yields a compostable material with superior mechanical and flame-retardant properties. Specifically, treatment of MC with a lecithin-phosphocholine emulsion makes sites available to modulate cellulose cross-linking through hydroxyl, phosphate and methylene groups, increasing the interaction between cellulose chains. The resultant bioleather exhibits enhanced tensile strength and high ductility. Bio-phosphorylation with lecithin also redirects the combustion pathway from levoglucosan production towards the formation of foaming char as an insulating oxygen barrier, for outstanding flame retardance. Controlled color modulation is demonstrated with natural dyes. Life cycle impact assessment reveals that MC bioleather has up to an order of magnitude lower carbon footprint than conventional textiles, and a thousandfold reduction in the carcinogenic impact of leather production. Eliminating the use of hazardous substances, these high performance materials disrupt linear production models and strategically eliminate its toxicity and negative climate impacts, with widespread application in fashion, interiors and construction. Importantly, the biotextile approach developed in this study demonstrates the potential of biofabrication coupled with green chemistry for a circular materials economy.