2022-02-01 フラウンホーファー研究機構

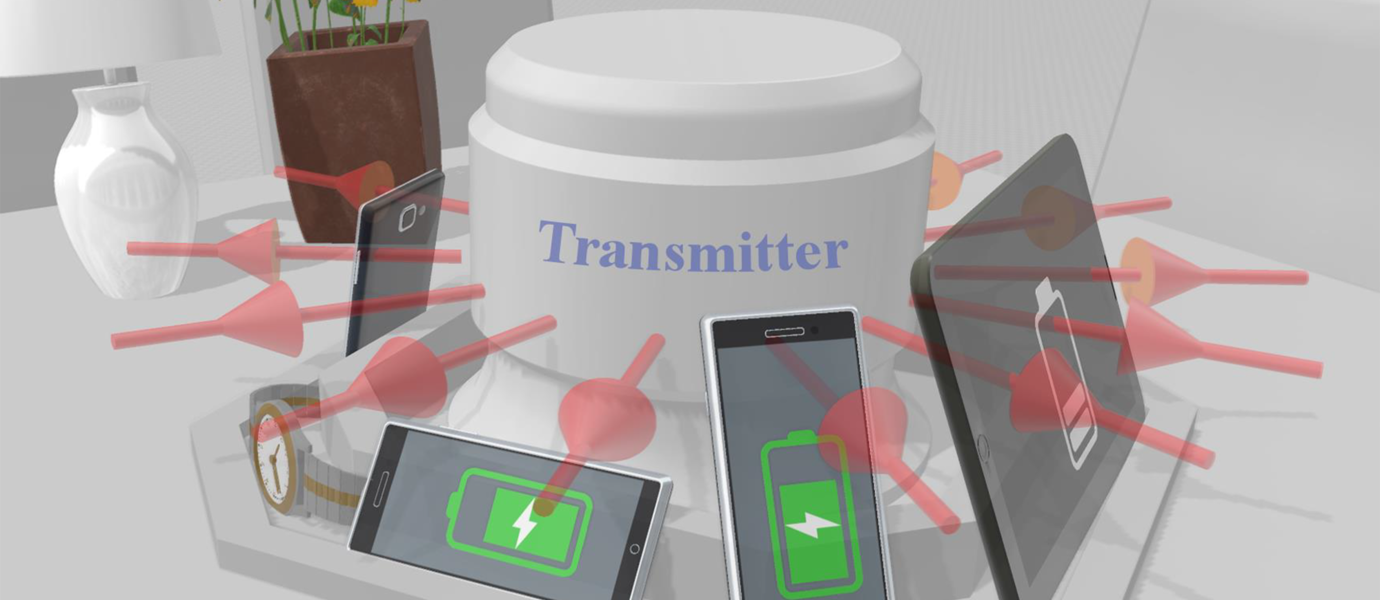

・このプロセスは、生体模倣効果を生み出すために、レーザーを用いてナノまたはマイクロ構造を表面に直接組み込むものです。このプロセスは非常に高速で、現在1分間に1平方メートルの表面を処理することができます。

・この技術は、フラウンホーファーIWS材料・ビーム技術研究所からスピンオフしたドレスデンの新興企業フュージョンバイオニックによって開発・販売されています。

© Fusion Bionic

© Fusion Bionic

Laser-functionalized glass with decorative Fusion Bionic logo inspired by the morpho butterfly.

© ronaldbonss.com

© ronaldbonss.com

Modern light interference technologies from Dresden now enable lotus effects and other refined structural tricks from the natural world to be transferred quickly to technical surfaces such as battery components, implants and even airplanes.

<関連情報>

- https://www.fraunhofer.de/en/press/research-news/2022/february-2022/lotus-effects-by-laser.html

- https://www.fraunhofer.de/content/dam/zv/en/press-media/2022/february/iws-fusion-bionic-lotus-effects-by-laser.pdf

A laser process for surface finishing Lotus effects by laser

Research News /

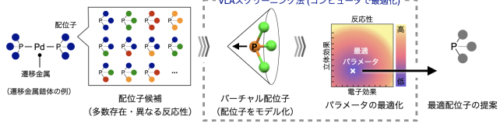

Nano- and microstructures can now be incorporated into surfaces in an instant using lasers. The technology is being developed and marketed by the Dresden-based start-up Fusion Bionic, a spin-off from the Fraunhofer Institute for Material and Beam Technology IWS. The possibilities are virtually endless when it comes to laser structuring. It has the advantage of being fast and much more versatile than coatings.

Product surfaces can be enhanced with all kinds of different effects. The lotus effect, for example, uses a microstructure to allow any dirt that might stick to the surface to simply wash away the next time it rains. The fine ripples of shark skin, meanwhile, improve the dynamics of air and water on the outside of airplanes and ships, thus saving fuel. With nature as their inspiration, many such effects have been developed by coating or applying a film to the surface into which the microstructures are incorporated. Coatings and films can wear away, however, causing the desired effect to diminish over time. In recent years, researchers at Fraunhofer IWS and Technische Universität Dresden have developed an alternative, market-ready method of permanently applying nano- and microstructures to surfaces: Direct Laser Interference Patterning (DLIP). This process incorporates the nano- or microstructure directly into the surface using a laser in order to create biomimetic effects. It is a remarkably quick process, and can currently handle up to one square meter of surface per minute. The new technology is so promising that it led to Fusion Bionic being founded this year as a spin-off from Fraunhofer IWS. Fusion Bionic develops and markets DLIP system solutions for biomimetic surface finishing, but also provides surface functionalization services to its customers.