2024-12-05 ペンシルベニア州立大学(PennState)

<関連情報>

- https://www.psu.edu/news/materials-research-institute/story/straining-materials-atomic-arrangement-may-make-cleaner-smarter

- https://onlinelibrary.wiley.com/doi/10.1002/adma.202408664

- https://www.nature.com/articles/nature02773

KNbO3薄膜における強誘電転移の巨大なひずみ制御 Colossal Strain Tuning of Ferroelectric Transitions in KNbO3 Thin Films

Sankalpa Hazra, Tobias Schwaigert, Aiden Ross, Haidong Lu, Utkarsh Saha, Victor Trinquet, Betul Akkopru-Akgun, Benjamin Z. Gregory, Anudeep Mangu, Suchismita Sarker …

Advanced Materials Published: 12 November 2024

DOI:https://doi.org/10.1002/adma.202408664

Abstract

Strong coupling between polarization (P) and strain (ɛ) in ferroelectric complex oxides offers unique opportunities to dramatically tune their properties. Here colossal strain tuning of ferroelectricity in epitaxial KNbO3 thin films grown by sub-oxide molecular beam epitaxy is demonstrated. While bulk KNbO3 exhibits three ferroelectric transitions and a Curie temperature (Tc) of ≈676 K, phase-field modeling predicts that a biaxial strain of as little as −0.6% pushes its Tc > 975 K, its decomposition temperature in air, and for −1.4% strain, to Tc > 1325 K, its melting point. Furthermore, a strain of −1.5% can stabilize a single phase throughout the entire temperature range of its stability. A combination of temperature-dependent second harmonic generation measurements, synchrotron-based X-ray reciprocal space mapping, ferroelectric measurements, and transmission electron microscopy reveal a single tetragonal phase from 10 K to 975 K, an enhancement of ≈46% in the tetragonal phase remanent polarization (Pr), and a ≈200% enhancement in its optical second harmonic generation coefficients over bulk values. These properties in a lead-free system, but with properties comparable or superior to lead-based systems, make it an attractive candidate for applications ranging from high-temperature ferroelectric memory to cryogenic temperature quantum computing.

歪みSrTiO3における室温強誘電性 Room-temperature ferroelectricity in strained SrTiO3

J. H. Haeni,P. Irvin,W. Chang,R. Uecker,P. Reiche,Y. L. Li,S. Choudhury,W. Tian,M. E. Hawley,B. Craigo,A. K. Tagantsev,X. Q. Pan,S. K. Streiffer,L. Q. Chen,S. W. Kirchoefer,J. Levy & D. G. Schlom

Nature Accepted:22 June 2004

DOI:https://doi.org/10.1038/nature02773

Abstract

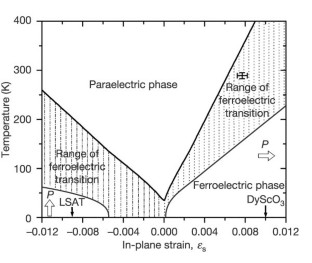

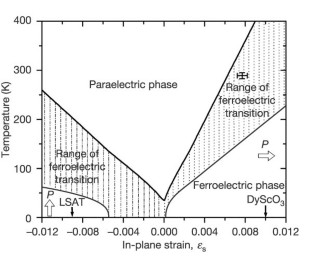

Systems with a ferroelectric to paraelectric transition in the vicinity of room temperature are useful for devices. Adjusting the ferroelectric transition temperature (Tc) is traditionally accomplished by chemical substitution—as in BaxSr1-xTiO3, the material widely investigated for microwave devices in which the dielectric constant (εr) at GHz frequencies is tuned by applying a quasi-static electric field1,2. Heterogeneity associated with chemical substitution in such films, however, can broaden this phase transition by hundreds of degrees3, which is detrimental to tunability and microwave device performance. An alternative way to adjust Tc in ferroelectric films is strain4,5,6,7,8. Here we show that epitaxial strain from a newly developed substrate can be harnessed to increase Tc by hundreds of degrees and produce room-temperature ferroelectricity in strontium titanate, a material that is not normally ferroelectric at any temperature. This strain-induced enhancement in Tc is the largest ever reported. Spatially resolved images of the local polarization state reveal a uniformity that far exceeds films tailored by chemical substitution. The high εr at room temperature in these films (nearly 7,000 at 10 GHz) and its sharp dependence on electric field are promising for device applications1,2.