2024-02-08 オークリッジ国立研究所(ORNL)

<関連情報>

- https://www.ornl.gov/news/new-process-allows-full-recovery-starting-materials-tough-polymer-composites

- https://www.cell.com/cell-reports-physical-science/fulltext/S2666-3864(23)00526-X

強靭でリサイクル可能な炭素繊維複合材料、調整されたビトリマー-繊維界面を介した卓越した界面接着性 Tough and recyclable carbon-fiber composites with exceptional interfacial adhesion via a tailored vitrimer-fiber interface

Md Anisur Rahman,Menisha S. Karunarathna,Christopher C. Bowland,… Dayakar Penumadu,Alexei P. Sokolov,Tomonori Saito

Cell Reports Physical Science Published:November 20, 2023

DOI:https://doi.org/10.1016/j.xcrp.2023.101695

Highlights

•Dynamic covalent bonding enhances vitrimer-fiber interface for superior strength

•Exceptional interfacial adhesion is achieved by tailoring fiber-matrix interfaces

•Closed-loop recycling of CFRPs is achieved by interfacial dynamic cross-linking

Summary

Carbon-fiber-reinforced polymers (CFRPs) offer improved energy efficiency in aerospace and automobile applications due to lightweight and mechanical robustness but face challenges with limited recyclability and frequent fiber-polymer delamination caused by inadequate interfacial adhesion. Here, we report an effective design of tough and closed-loop recyclable carbon-fiber-reinforced vitrimers (CFRVs) with exceptional interfacial adhesion through the synergy of a boronic ester-modified commodity polymer, multidiol cross-linker, and diol-functionalized carbon fibers (CFs). The dynamic covalent bonding between the vitrimer and fiber interface results in 43% higher interfacial adhesion than that of CFRVs with pristine CFs. Moreover, CFRVs with diol-CFs exhibit ∼731-MPa tensile strength, 26% higher than unmodified CFRVs and 49% higher than conventional epoxy CFRPs. Importantly, the dynamic boronic ester exchange enables CFRV closed-loop recyclability, repairability, fast thermoformability, self-adhesion, and multicycle processability without compromising mechanical performance. The designed dynamic fiber-matrix interaction will open up a new paradigm of multifunctional CFRPs while providing a path toward closed-loop structural materials.

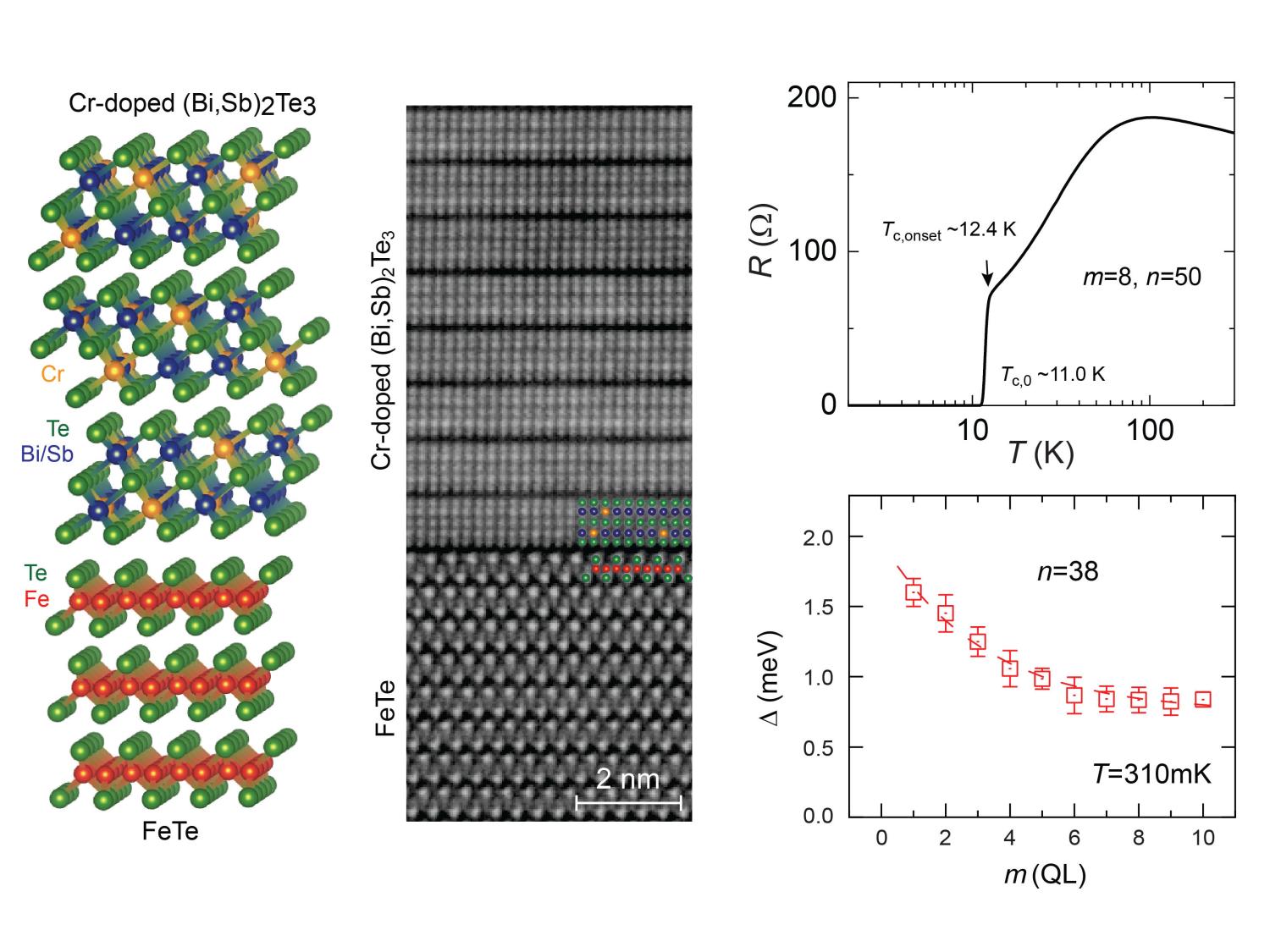

Graphical abstract