2023-06-06 カリフォルニア大学校アーバイン校(UCI)

A UCI-led team of engineers developed a method to 3D print glass micro- and nanostructures. Scanning electron microscope images show nanolattice structures on upper left to parabolic microlenses on upper right. The bottom row shows close-in details of the microscopic images, with a detail of a nanostructured Fresnel lens element on the lower right. Jens Bauer / UCI, KIT

◆この研究では、液体樹脂として「ポリヘドラルオリゴマーポリシルセスキオキサン(POSS)」分子を使用し、他の有機分子と組み合わせることで簡単な3Dプリントを実現しました。650度の加熱により有機成分が除去され、連続したガラスナノ構造が形成されます。この技術はシリカガラス以外の材料にも適用可能であり、統合回路において新たな可能性をもたらすとされています。国際特許も出願されています。

<関連情報>

- https://news.uci.edu/2023/06/06/uc-irvine-engineers-invent-a-way-to-3d-print-optical-grade-glass-at-the-nanoscale/

- https://www.science.org/doi/10.1126/science.abq3037

ナノスケールの光学グレードガラスを3Dプリントするためのシンタレスで低温なルート A sinterless, low-temperature route to 3D print nanoscale optical-grade glass

J. Bauer,C. Crook and T. Baldacchini

Science Published:1 Jun 2023

DOI:https://doi.org/10.1126/science.abq3037

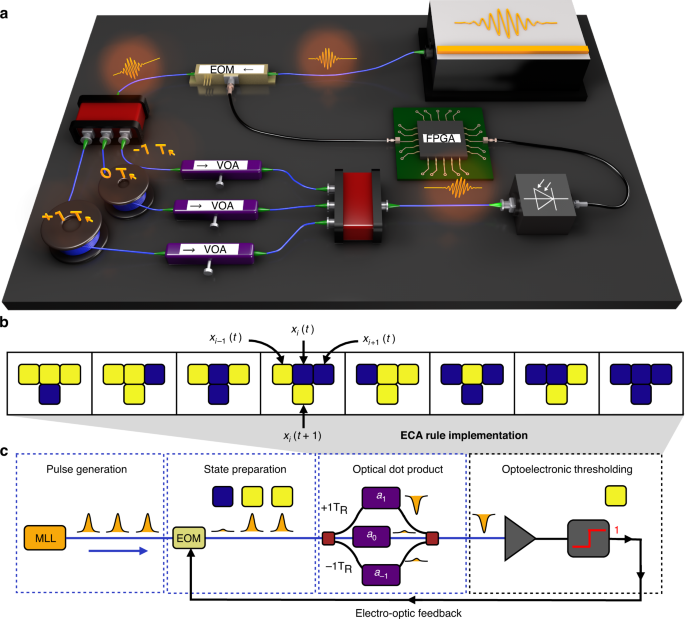

Editor’s summary

Printing glass with additive manufacturing techniques could provide access to new materials and structures for many applications. However, one key limitation to this is the high temperature usually required to cure glass. Bauer et al. used a hybrid organic-inorganic polymer resin as a feedstock material that requires a much lower temperature for curing (see the Perspective by Colombo and Franchin). The ability to form transparent, fused silica at only 650°C opens up different uses for the material. The glass produced has excellent spatial resolution, optical quality, and mechanical properties. —Brent Grocholski

Abstract

Three-dimensional (3D) printing of silica glass is dominated by techniques that rely on traditional particle sintering. At the nanoscale, this limits their adoption within microsystem technology, which prevents technological breakthroughs. We introduce the sinterless, two-photon polymerization 3D printing of free-form fused silica nanostructures from a polyhedral oligomeric silsesquioxane (POSS) resin. Contrary to particle-loaded sacrificial binders, our POSS resin itself constitutes a continuous silicon-oxygen molecular network that forms transparent fused silica at only 650°C. This temperature is 500°C lower than the sintering temperatures for fusing discrete silica particles to a continuum, which brings silica 3D printing below the melting points of essential microsystem materials. Simultaneously, we achieve a fourfold resolution enhancement, which enables visible light nanophotonics. By demonstrating excellent optical quality, mechanical resilience, ease of processing, and coverable size scale, our material sets a benchmark for micro– and nano–3D printing of inorganic solids.