2023+-05-03 韓国基礎科学研究院(IBS)

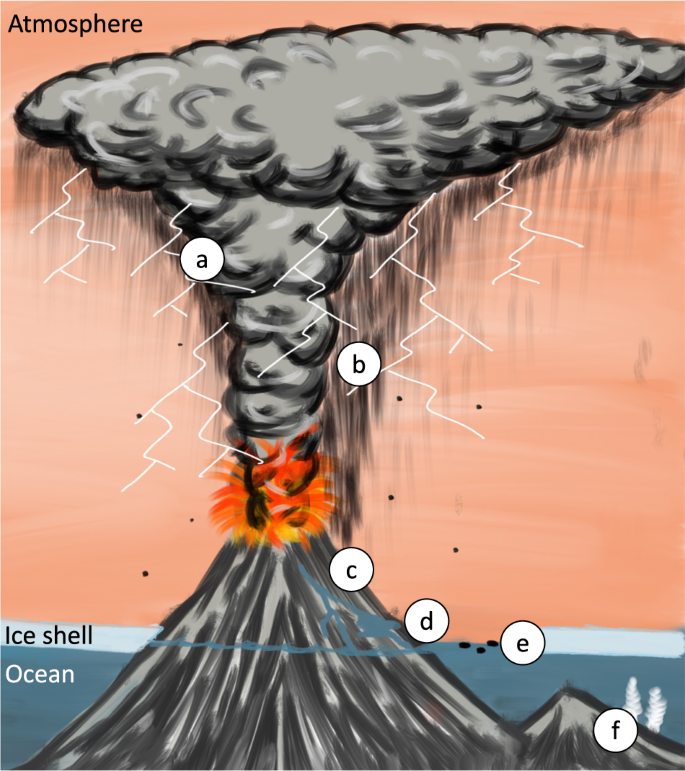

Figure 1. Segmented concentric-liquid reactor, a) cross-section of the reactor loaded with liquids, b) front view (along the axis of rotation) photograph of the actual rotor in the non-stirring mode, and c) side view of the rotor with the same content but in the stirring mode.

Figure 1. Segmented concentric-liquid reactor, a) cross-section of the reactor loaded with liquids, b) front view (along the axis of rotation) photograph of the actual rotor in the non-stirring mode, and c) side view of the rotor with the same content but in the stirring mode.

◆リチウムイオン電池のリサイクルは、水溶液を用いた冶金の一種である水冶法を広範囲に用いる必要があり、抽出-脱着の手順を何度も繰り返すことが必要で、複雑でコストがかかるため、リサイクル率が非常に低い。

◆韓国の研究グループが、液体層を回転させることで高濃度の混合物から貴重な金属を迅速に分離する技術を開発した。この新技術は、リチウム、ニッケル、コバルトなどの貴重な金属のリサイクルに使用され、従来の水冶法よりもコストを抑えて行われ、今後、他の貴重な金属の分離にも応用される可能性がある。

<関連情報>

- https://www.ibs.re.kr/cop/bbs/BBSMSTR_000000000738/selectBoardArticle.do?nttId=22746&pageIndex=1&searchCnd=&searchWrd=

- https://onlinelibrary.wiley.com/doi/abs/10.1002/adma.202211946

回転同心円型液体反応器によるリチウムイオン電池からの金属のワンポット3相リサイクルについて One-Pot, Three-Phase Recycling of Metals from Li-Ion Batteries in Rotating, Concentric-Liquid Reactors

Cristóbal Quintana, Olgierd Cybulski, Barbara Mikulak-Klucznik, Tomasz Klucznik, Bartosz A. Grzybowski

Advanced Materials Published: 16 March 2023

DOI:https://doi.org/10.1002/adma.202211946

Abstract

Efficient recycling of spent lithium-ion batteries, LIBs, is essential for making their numerous applications sustainable. Hydrometallurgy-based separation methods are an indispensable part of the recycling process but remain limited by the extraction efficiency and selectivity, and typically require numerous binary liquid-liquid extraction steps in which the capacity of the extracting organic phase or partition coefficient of extracted metals become an overall bottleneck. In this paper, we describe rotating reactors in which aqueous feed, organic extractant, and aqueous acceptor phases are all present in the same, rotating vessel and can be vigorously stirred and emulsified without the coalescence of aqueous layers. In this arrangement, the extractant molecules are not equilibrated with the feed and, instead, “shuttle” between the feed/extractant and the extractant/acceptor interfaces multiple times, with each such molecule ultimately transferring ∼10 metal ions. This shuttling allows for using extractant concentrations much lower than in previous designs even for extremely concentrated feeds and, simultaneously, ensures unprecedented speed and selectivity of the one-pot processes. These experimental results are accompanied by theoretical considerations of the selectivity versus speed trends as well as discussion of parameters essential for system’s upscaling.

This article is protected by copyright. All rights reserved