2026-02-20 九州大学

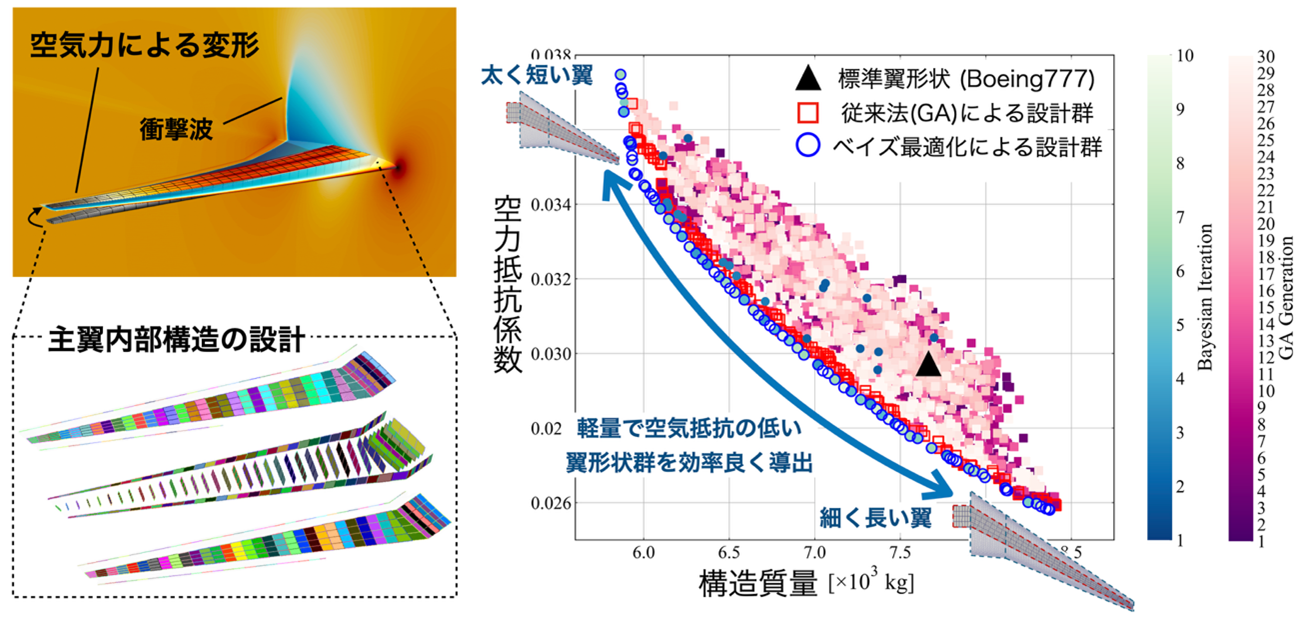

図1. AI手法の1つであるMBOにより計算コスト1/10で大型旅客機主翼の最適形状を導出

<関連情報>

- https://www.tohoku.ac.jp/japanese/2026/02/press20260220-01-AI.html

- https://www.tohoku.ac.jp/japanese/newimg/pressimg/tohokuuniv-press20260219_01web_AI.pdf

- https://www.sciencedirect.com/science/article/pii/S026382232600070X

様々な炭素繊維を用いた複合材航空機翼の多目的ベイズ最適化 Multi-objective Bayesian optimization of composite aircraft wings using various carbon fibers

Yajun Liu, Yoshiaki Abe, Ryosuke Kano, Yuki Yatsu, Katsumi Nakamura, Koji Shimoyama, Tomonaga Okabe, Shigeru Obayashi

Composite Structures Available online: 5 February 2026

DOI:https://doi.org/10.1016/j.compstruct.2026.120105

Highlights

- First comprehensive multi-objective Bayesian optimization of composite wings with varied fibers.

- Bayesian optimization converges faster and yields a more diverse Pareto front than NSGA-II.

- Two Pareto-front regions reveal distinct trade-offs between sweep angle and wingspan.

- Stiffer, stronger fibers reduce wing weight, though components depend on planform.

- Reduced compressive strength from fiber misalignment strongly affects wing weight and failure.

Abstract

This study presents the first application of multi-objective Bayesian optimization (MBO) for designing carbon fiber reinforced plastic (CFRP) aircraft wing planforms. The design process integrates two-way aeroelastic coupling and structural sizing analyses. Compared to the conventional NSGA-II genetic algorithm, MBO generated a more diverse and advanced Pareto front using only one-tenth of the function evaluations under the given problem and optimization parameters. The resultant Pareto front revealed two distinct design regions: one characterized by a constant minimum wingspan and varying sweep angle, and the other by a constant maximum sweep with increasing wingspan, offering new insight into aerodynamic–structural trade-offs in composite wing design. Among three carbon fibers (T700S, T800S, and T1100G), higher-stiffness fibers consistently reduced total wing weight, while component-level sensitivity differed with geometry. The result first reports the effects of fiber properties on comprehensive Pareto-optimal solutions using global optimization via the MBO approach. Furthermore, the reduction in compressive strength was evaluated by integrating the inevitable fiber misalignment angle during manufacturing into the micromechanics (Budiansky–Fleck) model, and the wing weight was estimated accordingly. Such a misalignment significantly affected the weight and failure modes of the upper skin, especially for the high-aspect-ratio wing design.