2026-01-14 浙江大学(ZJU)

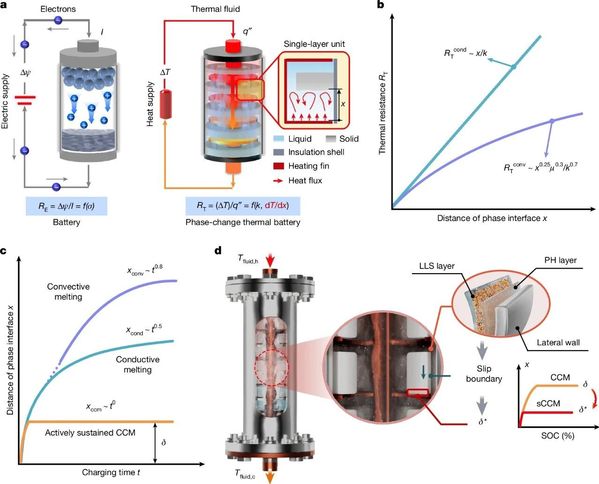

Fast charging of phase-change thermal batteries

<関連情報>

- https://www.zju.edu.cn/english/2026/0114/c19573a3128338/page.psp

- https://www.nature.com/articles/s41586-025-09877-0

パルス加熱とスリップが相変化熱電池の充電を強化 Pulse heating and slip enhance charging of phase-change thermal batteries

Zi-Rui Li (李梓瑞),Nan Hu (胡楠),Zhen-Bo Wang (汪振波),Guo-Tao Fu (傅国涛),Yang-Yan Lai (赖洋琰),Yue-Fei Wu (武岳飞),Jia-Jie Jiang (蒋佳杰),Xiao-Rong Wang (王晓容),Shuang-Shuang Ni (倪爽爽),Yu-Min Ye (叶羽敏),Zi-Tao Yu (俞自涛),Xiang Gao (高翔),Howard A. Stone & Li-Wu Fan (范利武)

Nature Published:07 January 2026

DOI:https://doi.org/10.1038/s41586-025-09877-0

Abstract

Phase-change thermal batteries for renewable energy storage and waste heat recovery demand high energy density and fast charging1,2,3,4,5, which are mutually exclusive because phase-change materials (PCMs) with high melting enthalpy are usually poor heat conductors6,7,8. The charging rate can be improved by making composite phase-change materials (CPCMs) with increased thermal conductivity9 and/or by exerting an external force to realize close-contact melting (CCM)10,11,12. However, these methods inevitably result in energy density losses and/or extra energy consumption. Here we report a strategy to boost the charging rates without sacrificing energy density, based on a rational design of a composite coating that enables slip-enhanced close-contact melting (sCCM) inside sealed thermal batteries. Using organic PCMs, we demonstrate a record-high power density of 1,100 ± 2% kW m−3 in a prototype. Our coating design integrates a pulse-heated (PH) layer that premelts the PCM to initiate CCM, together with a liquid-like slip surface that ensures unimpeded sinking of the remaining solid and sustains the sCCM mode throughout charging. We develop a model to explain how the slip surface enhances the charging rate. With high cycling life, adaptability and scalability, this strategy is generalizable to diverse PCMs, enabling high-performance thermal energy storage over a wide range of temperatures.