2025-012-23 バージニア工科大学(Virginia Tech)

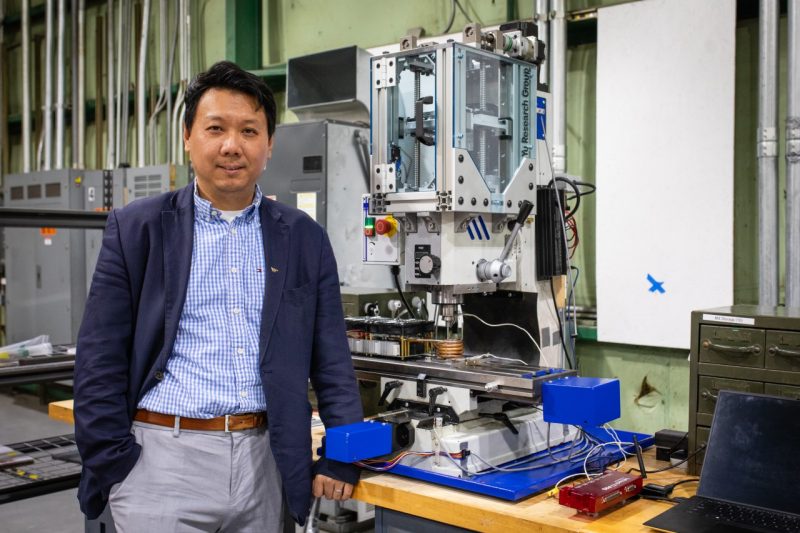

Hang Yu, associate professor of materials science and engineering, with a miniaturized additive friction stir deposition machine used in his advanced manufacturing research. Photo by Peter Means for Virginia Tech.

<関連情報>

- https://news.vt.edu/articles/2026/01/eng-mse-long-quest-smart-composite-breakthrough.html

- https://www.sciencedirect.com/science/article/abs/pii/S0927796X2500230X

形状記憶セラミック強化複合材料の固体積層造形 Solid-state additive manufacturing of shape-memory ceramic reinforced composites

Donald J. Erb, Nikhil Gotawala, Hang Z. Yu

Materials Science and Engineering: R: Reports Available online: 22 December 2025

DOI:https://doi.org/10.1016/j.mser.2025.101152

Highlights

- Additive friction stir deposition of metal matrix-SMC composites is successful.

- The printed composites are fully dense with particle dispersion and size reduction.

- Metal-ceramic interfaces formed during printing dictate thermal transformation.

- Stress-induced transformation is achieved in bulk composites for the first time.

- Load transfer and strain hardening of matrix govern stress-induced transformation.

Abstract

We report a solid-state additive manufacturing route for producing shape-memory ceramic (Zr0.88Ce0.12O2) reinforced metal matrix composites. Using additive friction stir deposition, we implement two feedstock engineering strategies: (i) pre-mixing of powders using a Cu matrix and (ii) hole-pattern drilling using an Al-Mg-Si matrix, where the specific matrix materials are chosen for their distinct shear flow behaviors. The process yields fully dense composites with uniform particle dispersion (20 vol%) and dynamically recrystallized metal matrices. The severe thermomechanical processing conditions also reduce the ceramic particle size, resulting in unique composite microstructures unattainable by alternative processing routes. The as-printed composites can withstand high compressive loads without cracking and retain functionality enabled by thermally and mechanically triggered martensitic transformations. Notably, for the first time, stress-induced martensitic transformation (tetragonal to monoclinic) is observed in bulk-scale composites—but it is only present in the Cu matrix composite, not the Al-Mg-Si counterpart. Micromechanics modeling attributes this contrast to differences in the load transfer and strain hardening capabilities. Complementary to global transformation characterization, Raman mapping reveals that transformation typically initiates at the particle-matrix interface. Together, these results establish a potential pathway for scalable manufacturing of multi-functional metal–shape memory ceramic composites with tunable microstructures and transformation responses.