2025-11-12 マサチューセッツ工科大学(MIT)

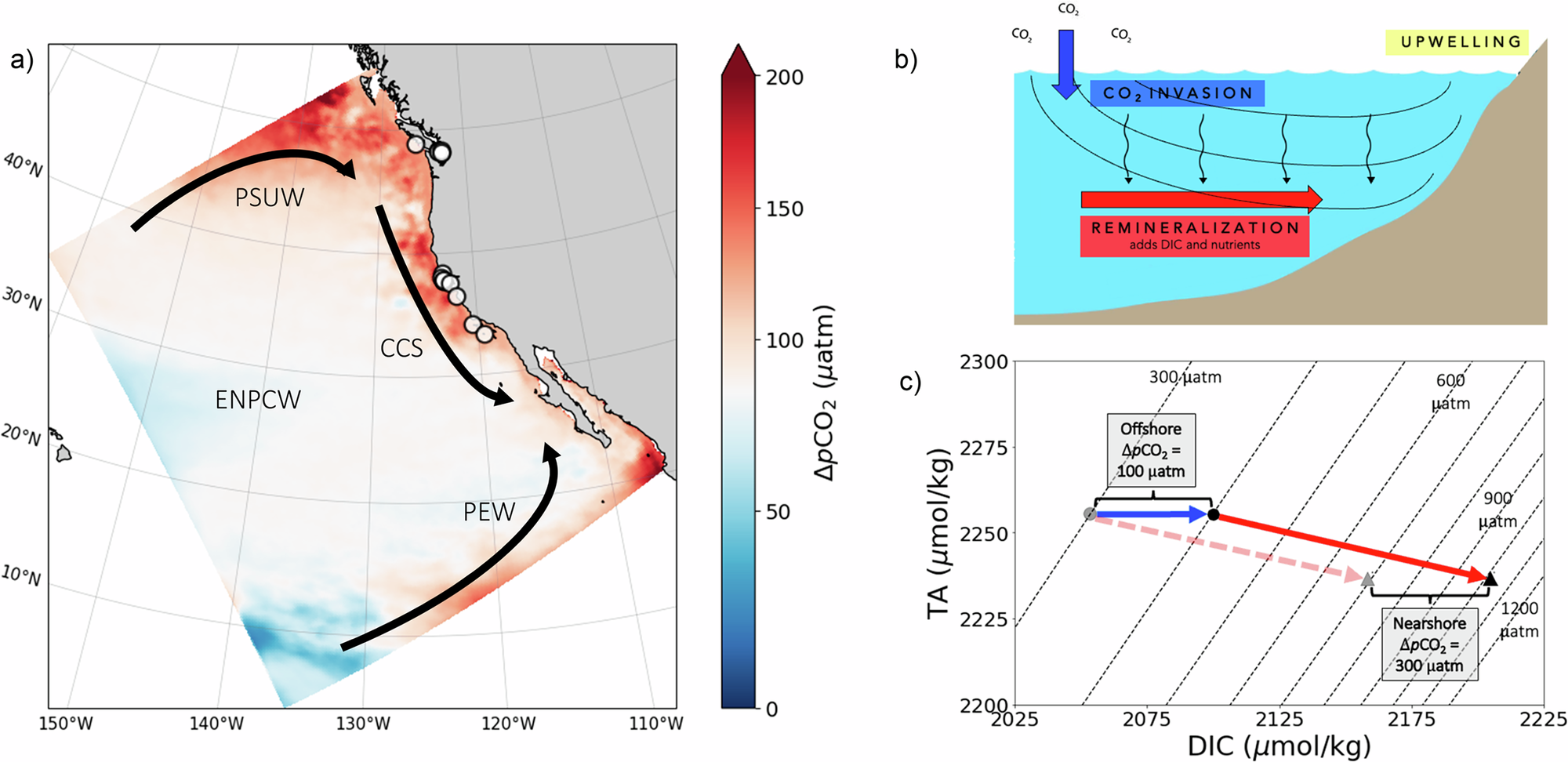

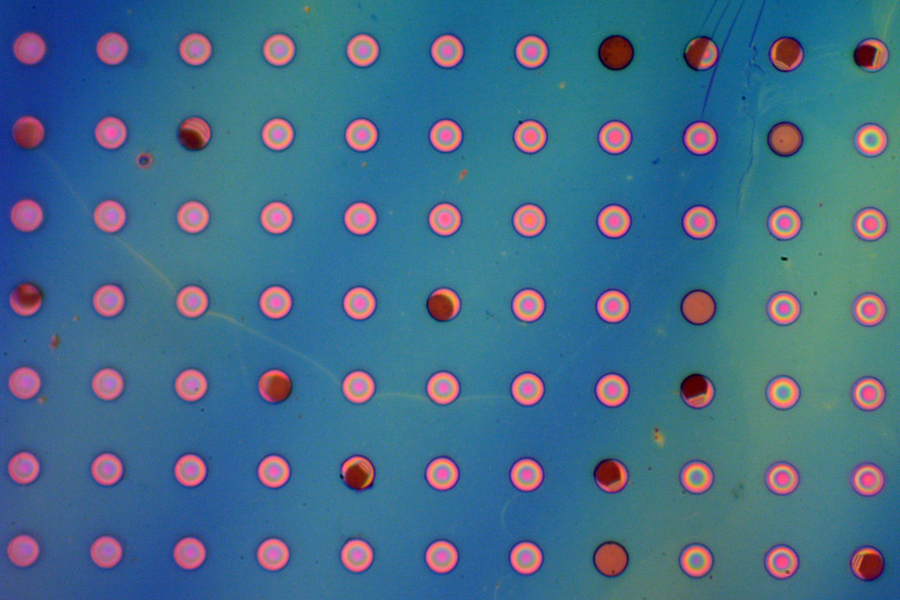

MIT researchers tested the gas permeability of their new polymer films by suspending them over microwells to form bubbles. Some bubbles from 2021 experiments are still inflated. This optical micrograph shows how the films form very colorful spots when suspended over microwells.Image: Courtesy of the researchers

MIT researchers tested the gas permeability of their new polymer films by suspending them over microwells to form bubbles. Some bubbles from 2021 experiments are still inflated. This optical micrograph shows how the films form very colorful spots when suspended over microwells.Image: Courtesy of the researchers

<関連情報>

- https://news.mit.edu/2025/new-lightweight-polymer-film-can-prevent-corrosion-1112

- https://www.nature.com/articles/s41586-025-09674-9

二次元ポリアラミドから作られた分子不透過性ポリマー A molecularly impermeable polymer from two-dimensional polyaramids

Cody L. Ritt,Michelle Quien,Zitang Wei,Hagen Gress,Mohan T. Dronadula,Kaan Altmisdort,Huong Giang T. Nguyen,Christopher D. Zangmeister,Yu-Ming Tu,Sanjay S. Garimella,Shahab Amirabadi,Michael Gadaloff,Weiguo Hu,Narayana R. Aluru,Kamil L. Ekinci,J. Scott Bunch & Michael S. Strano

Nature Published:25 September 2025

DOI:https://doi.org/10.1038/s41586-025-09674-9

Abstract

All polymers exhibit gas permeability through the free volume of entangled polymer chains1,2,3. By contrast, two-dimensional (2D) materials including graphene stack densely and can exhibit molecular impermeability4,5,6. Solution-synthesized 2D polymers that exhibit the latter by poly-condensation have been a longstanding goal. Herein, we demonstrate self-supporting, spin-coated 2D polyaramid nanofilms that exhibit nitrogen permeability below 3.1 × 10−9 Barrer, nearly four orders of magnitude lower than every class of existing polymer, and similar for other gases tested (helium, argon, oxygen, methane and sulfur hexafluoride). Optical interference during the pressurization of nanofilm-coated microwells allows measurement of mechanosensitive rim opening and sealing, creating gas-filled bulges that are stable exceeding three years. This discovery enables 2D polymer resonators with high resonance frequencies (about 8 MHz) and quality factors up to 537, similar to graphene. A 60-nm coating of air-sensitive perovskites reduces the lattice degradation rate 14-fold with an oxygen permeability of 3.3 × 10−8 Barrer. Molecularly impermeable polymers promise the next generation of barriers that are synthetically processable, chemically amenable and maximize molecular rejection with minimal material, ultimately advancing sustainability goals.