2025-06-06 ペンシルベニア州立大学 (Penn State)

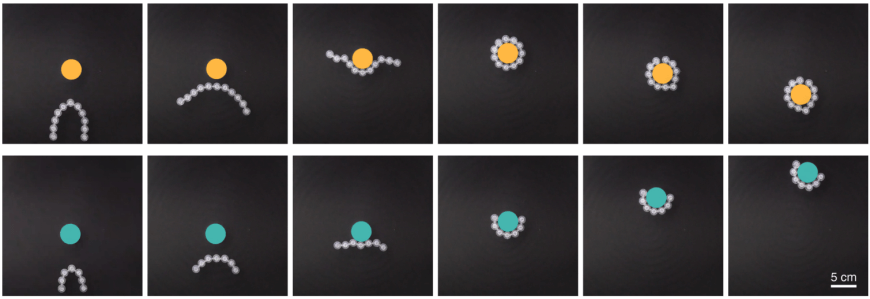

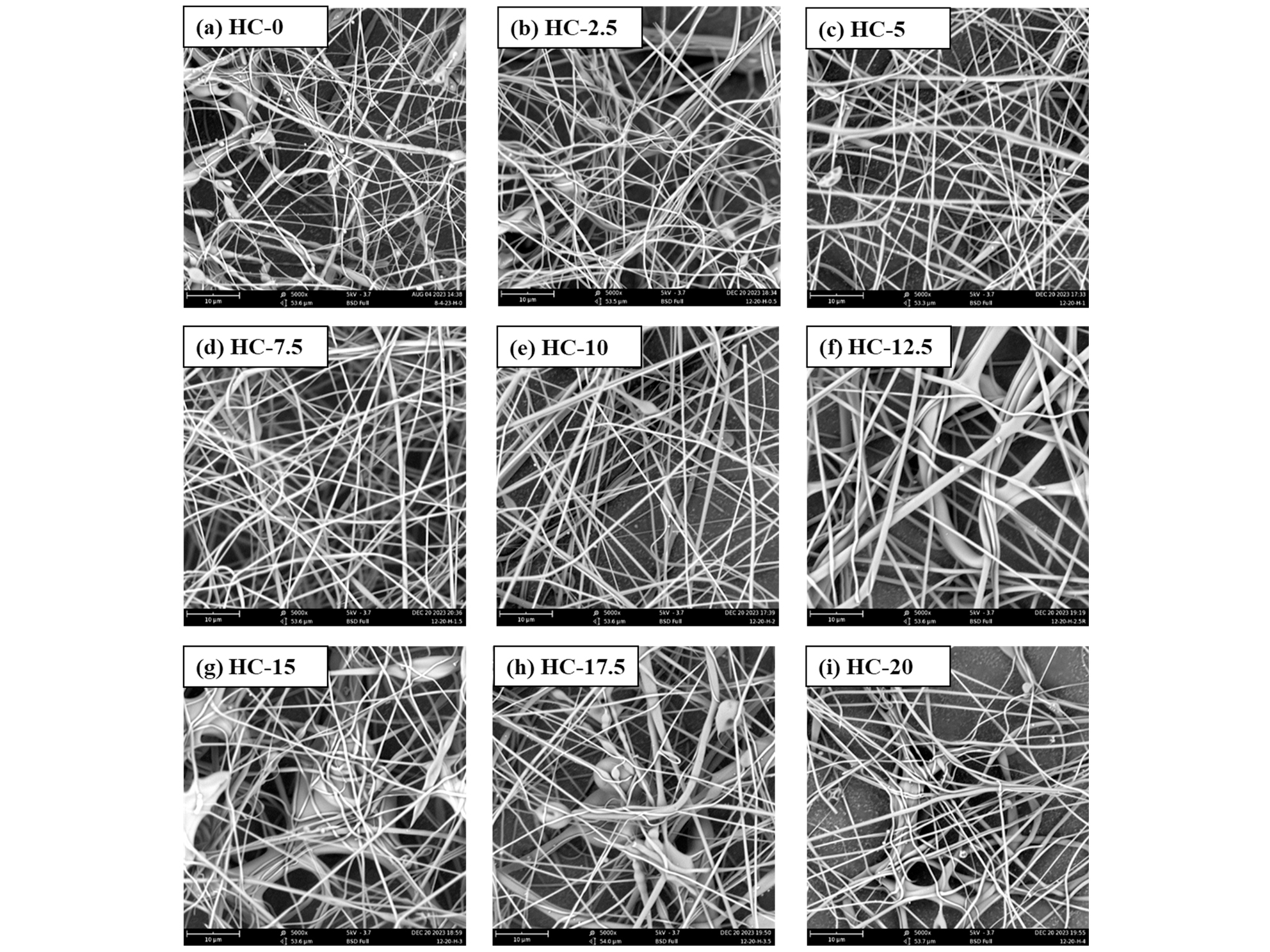

Milk protein and cellulose derived from plants can be electrospun into thin fibers for use in mats that could be used for biodegradable and edible food packaging, according to a new study by researchers at Penn State. Pictured here are variations in the composition of fibers made from different ratios of milk protein and cellulose. Credit: Penn State. Creative Commons

Milk protein and cellulose derived from plants can be electrospun into thin fibers for use in mats that could be used for biodegradable and edible food packaging, according to a new study by researchers at Penn State. Pictured here are variations in the composition of fibers made from different ratios of milk protein and cellulose. Credit: Penn State. Creative Commons

<関連情報>

- https://www.psu.edu/news/research/story/edible-biodegradable-fibers-made-milk-protein-cellulose

- https://www.sciencedirect.com/science/article/abs/pii/S0021979725009920

カゼイン-ヒドロキシプロピルメチルセルロースナノファイバーの作製と物理力学的性能 Fabrication and physicomechanical performance of casein-hydroxypropyl methylcellulose nanofibers

Deepika Sharma, Federico M. Harte, Gregory R. Ziegler

Journal of Colloid and Interface Science Available online: 14 April 2025

DOI:https://doi.org/10.1016/j.jcis.2025.137601

Abstract

Nanofibers were electrospun (20 kV, 6 mL/h, 10 cm, 8 h) from a phase-separated mixture of hydroxypropyl methylcellulose (HPMC) and molecularly dispersed casein. Associative phase separation resulted in a dope comprising a gel-like coacervate phase dispersed in a casein solution with a third phase comprising casein aggregates. Beadless fibers of 535 nm average diameter, a maximum specific surface area of 3.3 m2/g, and maxima in Young’s modulus and tensile strength were spun from a dope containing 1.5 % w/v HPMC and 18.5 % w/v acid casein in 50 % v/v aqueous ethanol at pH 10 demonstrating a minimum in surface tension. Classic spindle-shaped beads resulting from Rayleigh instability were observed at lower HPMC concentrations as were thickened, irregular fibers likely resulting from the unique phase behavior at higher HPMC levels. At 100 % relative humidity, the fiber mats readily adsorbed moisture, causing their transformation into clear films. Reinforcement with HPMC produced casein-rich nanofibers with improved mechanical strength and potential utility in food, biomedical, or cosmetic applications.