2025-03-20 カリフォルニア工科大学(Caltech)

<関連情報>

- https://www.caltech.edu/about/news/harnessing-sunlight-to-make-sustainable-fuels

- https://www.cell.com/device/abstract/S2666-9986(24)00550-7

持続可能な燃料合成のための光熱触媒反応器と選択的太陽光吸収体 A photothermocatalytic reactor and selective solar absorber for sustainable fuel synthesis

Magel P. Su∙ Aisulu Aitbekova∙ Matthew Salazar∙ … ∙ Jonas C. Peters∙ Theodor Agapie∙ Harry A. Atwater

Device Published:November 8, 2024

DOI:https://doi.org/10.1016/j.device.2024.100604

Graphical abstract

The bigger picture

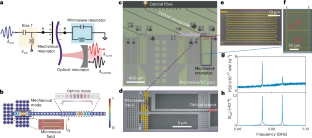

While carbon-neutral energy technologies have gained widespread interest in combating anthropogenic climate change, there exist certain scenarios where energy storage is still largely limited to carbon-based fuel, such as in the aviation transportation industry. A photothermocatalytic reactor converts solar energy into thermal heating that can be used to run the chemical reactions required to generate fuels. In addition to having high solar-to-thermal energy conversion efficiency, the reactor has to be scalable and affordable. These stringent requirements present a challenge in designing a photothermocatalytic reactor. We demonstrate a photothermal reactor that converts ethylene into long-chain hydrocarbons, a vital step for generating solar fuels, using sunlight. Furthermore, the reactor lends itself toward large-scale production, suggesting potential for industrial-scale output in the future. Ultimately, this work explores the practical application of sunlight for generating sustainable aviation fuels to combat climate change.

Highlights

•Solar thermal heating enables sustainable generation of fuels and chemicals

•A photothermocatalytic reactor with a solar absorber produces solar thermal heating

•Solar-driven ethylene oligomerization yields liquid hydrocarbons

Summary

Utilizing solar thermal energy for thermochemical processes enables the sustainable generation of fuels and chemicals. Here, we present a scalable photothermocatalytic reactor with a selective solar absorber that converts sunlight into thermal energy for fuel synthesis. The absorber achieves a maximum temperature of 249°C under one-sun illumination and 130°C under ambient operating conditions (25°C, 1 atm). The application of the photothermocatalytic reactor was demonstrated using an ethylene oligomerization reaction, which is used in industry. A homogeneous reaction was performed in a batch mode and yielded a distribution of liquid hydrocarbons with 6–24 carbon atoms. A heterogeneous reaction was performed in a flowthrough configuration, yielding butene and hexene products. Finally, simulated results for a larger-scale reactor predict spatially uniform maximum temperatures up to 120°C and 210°C under one- and three-sun illumination, demonstrating the potential to generate fuels at bigger scales.