2025-01-16 ウースター工科大学(WPI)

<関連情報>

- https://www.wpi.edu/news/announcements/wpi-professor-yan-wang-publishes-article-lithium-ion-battery-recycling-inaugural-nature-reviews

- https://www.nature.com/articles/s44359-024-00010-4

リチウムイオン電池リサイクルの進化 The evolution of lithium-ion battery recycling

Xiaotu Ma,Zifei Meng,Marilena Velonia Bellonia,Jeffrey Spangenberger,Gavin Harper,Eric Gratz,Elsa Olivetti,Renata Arsenault & Yan Wang

Nature Reviews Clean Technology Published:15 January 2025

DOIhttps://doi.org/10.1038/s44359-024-00010-4

Abstract

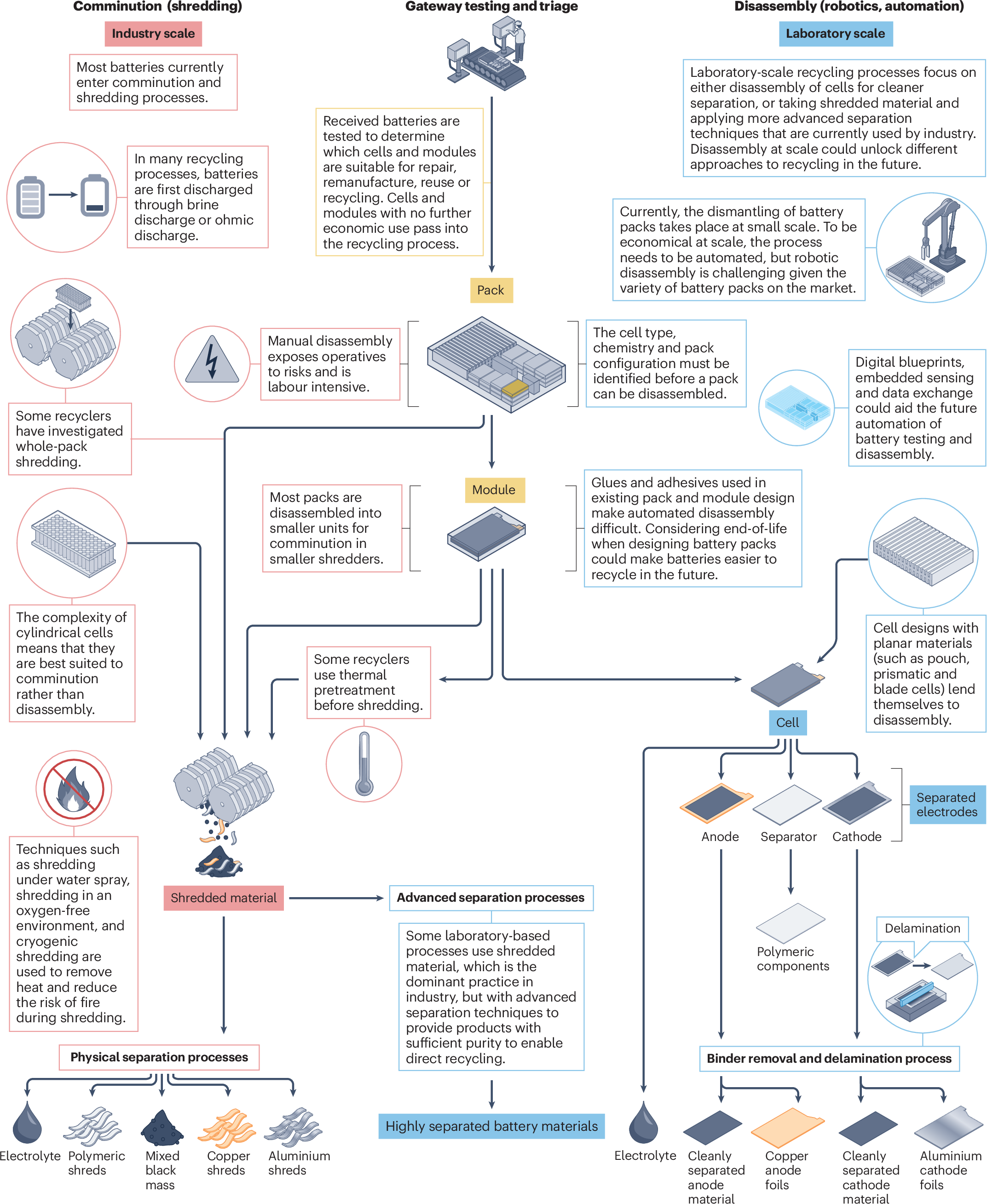

Demand for lithium-ion batteries (LIBs) is increasing owing to the expanding use of electrical vehicles and stationary energy storage. Efficient and closed-loop battery recycling strategies are therefore needed, which will require recovering materials from spent LIBs and reintegrating them into new batteries. In this Review, we outline the current state of LIB recycling, evaluating industrial and developing technologies. Among industrial technologies, pyrometallurgy can be broadly applied to diverse electrode materials but requires operating temperatures of over 1,000 °C and therefore has high energy consumption. Hydrometallurgy can be performed at temperatures below 200 °C and has material recovery rates of up to 93% for lithium, nickel and cobalt, but it produces large amounts of wastewater. Developing technologies such as direct recycling and upcycling aim to increase the efficiency of LIB recycling and rely on improved pretreatment processes with automated disassembly and cleaner mechanical separation. Additionally, the range of materials recovered from spent LIBs is expanding from the cathode materials recycled with established methods to include anode materials, electrolytes, binders, separators and current collectors. Achieving an efficient recycling ecosystem will require collaboration between recyclers, battery manufacturers and electric vehicle manufacturers to aid the design and automation of battery disassembly lines.