2025-11-18 中国科学院(CAS)

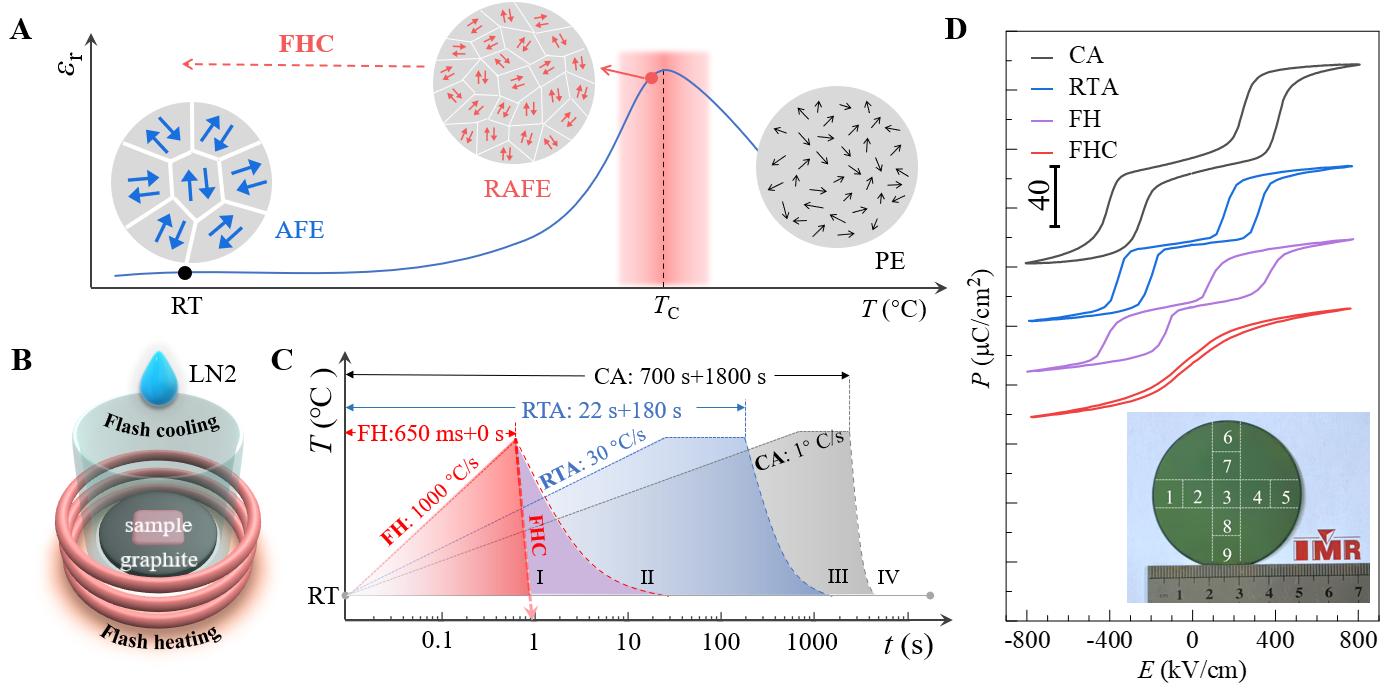

Rational design principles of relaxor antiferroelectric materials. A. Temperature-dependent dielectric permittivity (εr) of an antiferroelectric (AFE) material, with schematic domain structures illustrate at different temperatures; B. The experimental setup for flash heating and flash cooling (FHC), capable of achieving rates up to 1000 °C/s, enabling the synthesis of relaxor AFE films in just one second; C. Comparison of various heat treatment protocols, with treatment times ranging from under 1 second for FHC to over 1000 seconds for conventional annealing (CA); D. P–E hysteresis loops of PbZrO3 films subjected to various annealing processes. The inset shows a 2-inch wafer-scale relaxor AFE film fabricated via FHC. (Image by IMR)

<関連情報>

- https://english.cas.cn/newsroom/research_news/tech/202511/t20251118_1116508.shtml

- https://www.science.org/doi/10.1126/sciadv.ady2349

フラッシュアニール処理によるウェーハスケールのリラクサー反強誘電体の作製とエネルギー貯蔵性能の向上 Flash annealing–engineered wafer-scale relaxor antiferroelectrics for enhanced energy storage performance

Yizhuo Li, Kepeng Song, Meixiong Zhu, Xiaoqi Li, […] , and Weijin Hu

Science Advances Published:14 Nov 2025

DOI:https://doi.org/10.1126/sciadv.ady2349

Abstract

Dielectric capacitors are essential for energy storage systems because of their high-power density and fast operation speed. However, optimizing energy storage density with concurrent thermal stability remains a substantial challenge. Here, we develop a flash annealing process with ultrafast heating and cooling rates of 1000°C per second, which facilitates the rapid crystallization of PbZrO3 film within a mere second, while locking its high-temperature microstructure to room temperature. This produces compact films with subgrain boundary fractions of 36%, nanodomains of several nanometers, and negligible lead volatilization. These contribute to relaxor antiferroelectric film with a high breakdown strength (4800 kilovolts per centimeter) and large polarization (70 coulombs per square centimeter). Consequently, we have achieved a high energy storage density of 63.5 joules per cubic meter and outstanding thermal stability with performance degradation less than 3% up to 250°C. Our approach is extendable to ferroelectrics like Pb(Zr0.52Ti0.48)O3 and on wafer scale, providing on-chip nonlinear dielectric energy storage solutions with industrial scalability.