2025-05-20 パシフィック・ノースウェスト国立研究所(PNNL)

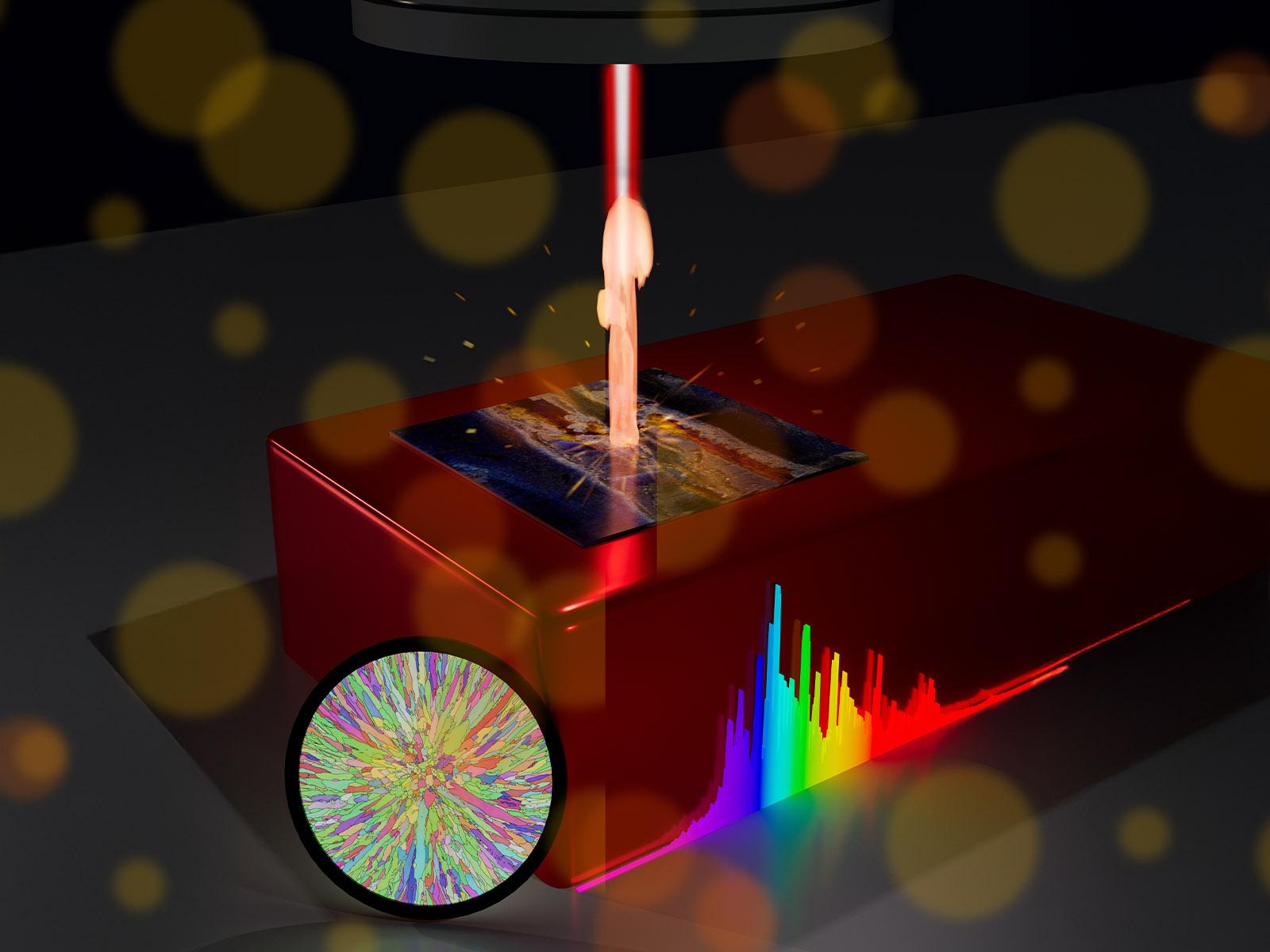

The light emissions from weld plasma are related to the composition of particles in the plume, which differs from the original metal in elemental makeup. (Image by Cortland Johnson | Pacific Northwest National Laboratory)

<関連情報>

- https://www.pnnl.gov/publications/using-plasma-color-predict-weld-quality

- https://advanced.onlinelibrary.wiley.com/doi/10.1002/adem.202302177

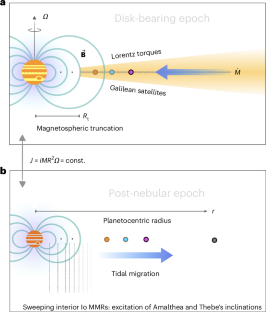

プラズマ凝縮物質とメルトプール物質間の組成分画の光学的証拠 Optical Evidence of Compositional Fractioning between Plasma-Condensed and Melt Pool Matter

Lance Hubbard, Floyd Hilty, Ankit Roy, Sarah Miley, Nicole Overman, Scott Muller, Kevin R. Fiedler, Diana Horangic, Matt Olszta

Advanced Engineering Materials Published: 10 March 2024

DOI:https://doi.org/10.1002/adem.202302177

Abstract

Control of multicomponent alloys during welding is challenging because it lacks a real-time understanding of composition. The optical emissions of plasma formed during laser-induced metal welding correlate with the composition of particles ejected from the melt pool. Plasma emissions observed in this study contain large iron, manganese, chrome, and copper signatures, which match the composition of emitted particles. Particles recovered closest to the melt pool exhibit a core–shell morphology that is composed of iron-manganese-chrome intermetallic cores within copper shells. Particles collected farther from the melt pool, do not share this core–shell morphology, though similar elemental compositions are observed. The correlation between plasma optical emissions and particle composition can be used to predict the composition of the melt pool, allowing for real-time welding and sintering control.