2025-04-07 米国国立標準技術研究所 (NIST)

<関連情報>

- https://www.nist.gov/news-events/news/2025/04/rare-crystal-shape-found-increase-strength-3d-printed-metal

- https://www.sciencedirect.com/science/article/abs/pii/S0925838825018390

積層造形法を用いて作製した高強度アルミニウム合金の組織特徴と準安定相形成 Microstructural Features and Metastable Phase Formation in a High-Strength Aluminum Alloy Fabricated Using Additive Manufacturing

A.D. Iams, J.S. Weaver, B.M. Lane, L.A. Giannuzzi, F. Yi, D.L. LaPlant, J.H. Martin, F. Zhang

Journal of Alloys and Compounds Available online: 7 April 2025

DOI:https://doi.org/10.1016/j.jallcom.2025.180281

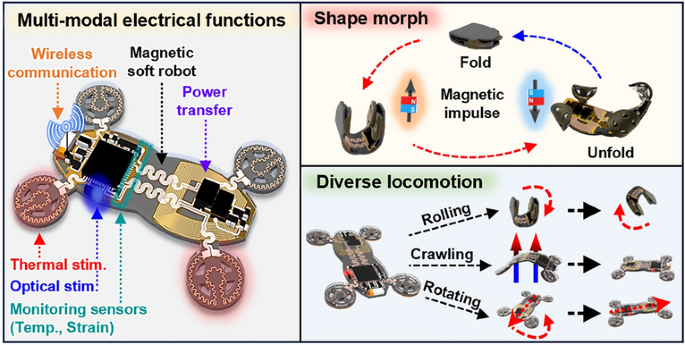

Graphical abstract

Highlights

- Two metastable phases, cuboidal Al3Zr and icosahedral quasicrystals, were identified in the as-fabricated AA7A77 alloy.

- Cuboidal Al3Zr precipitates form within fine equiaxed grains near the onset of solidification, acting as grain refiners.

- Icosahedral quasicrystals (Mg₃₂(Al, Zn, Cu)₄₉) form interdendritically and along grain boundaries near the end of solidification.

- The icosahedral quasicrystals contribute to enhanced hardness, with the as-fabricated alloy exhibiting a hardness comparable to the peak-aged AA7075.

- Spatially resolved nanoindentation data reveal a correlation between grain structures and mechanical properties, with fine grain regions showing higher hardness than coarse grain regions.

Abstract

Additive manufacturing (AM) has opened new pathways for producing high-strength aluminum alloy components. However, optimizing their mechanical performance require a detailed understanding of microstructural evolution. In this study, a multi-length-scale microstructural and computational analysis was conducted on a commercially available, precipitation-hardenable aluminum alloy (AA7A77) in the as-fabricated condition. A distinct bimodal microstructure influenced by the solidification process was observed, with fine equiaxed grains near the melt-pool boundaries and coarse elongated grains within the center of the melt pool. Two key metastable phases were identified: the cuboidal L12 Al3Zr phase within fine grains and the icosahedral Mg32(Al, Zn, Cu)49 quasicrystal located within coarse grains and along grain boundaries. Computational simulations provided insight into the formation of the quasicrystals, where a secondary phase was predicted to form at the termination of solidification which is favorable to quasicrystal formation. Nanoindentation demonstrated a hardness comparable to peak-aged AA7075, which leads to the possibility of further improvement through a precipitation-hardening heat treatment. This work provides new insights into the microstructural characteristics of high-strength AM aluminum alloys and presents a novel pathway for leveraging quasicrystals for enhanced mechanical performance.