2025-03-10 中国科学院 (CAS)

<関連情報>

- https://english.cas.cn/newsroom/cas_media/202503/t20250310_903608.shtml

- https://link.springer.com/article/10.1007/s40820-025-01682-8

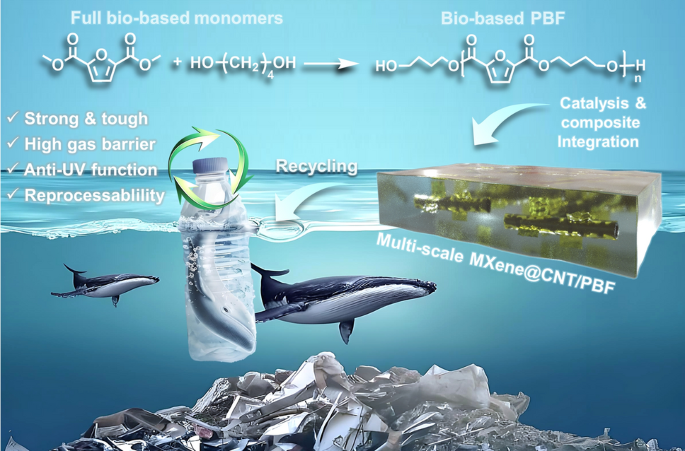

樹枝状MXene@CNTヘテロ構造によりその場で触媒され強化された、堅牢で再処理可能なバイオ再生可能ポリエステルナノ複合材料 Robust and Reprocessable Biorenewable Polyester Nanocomposites In Situ Catalyzed and Reinforced by Dendritic MXene@CNT Heterostructure

Hao Wang,Jiheng Ding,Hongran Zhao,Qinchao Chu,Jin Zhu & Jinggang Wang

Nano-Micro Letters Published:24 February 2025

DOI:https://doi.org/10.1007/s40820-025-01682-8

Highlights

- Structurally stable and well-dispersed dendritic MXene@CNT heterostructures with multiple roles (i.e., catalyst, nucleator, and interface enhancer of polyesters) were constructed.

- Biorenewable MXene@CNT/PBF (MCP) polyester nanocomposites with ultrahigh mechanical strength (≈101 MPa), stiffness (≈3.1 GPa), and toughness (≈130 MJ m−3) were synthesized via MXene@CNT in situ catalytic polymerization.

- Exceptional reprocessability, gas barrier (e.g., O2 0.0187 barrer), and UV resistance (e.g., resist 85% UVA rays) properties were achieved for the MCP, which can be employed as high-performance and multifunctional packaging materials for plastic replacement.

Abstract

Renewable 2,5-furandicarboxylic acid-based polyesters are one of the most promising materials for achieving plastic replacement in the age of energy and environmental crisis. However, their properties still cannot compete with those of petrochemical-based plastics, owing to insufficient molecular and/or microstructure designs. Herein, we utilize the Ti3C2Tx-based MXene nanosheets for decorating carbon nanotube (CNT) and obtaining the structurally stable and highly dispersed dendritic hetero-structured MXene@CNT, that can act as multi-roles, i.e., polycondensation catalyst, crystal nucleator, and interface enhancer of polyester. The bio-based MXene@CNT/polybutylene furandicarboxylate (PBF) (denoted as MCP) nanocomposites are synthesized by the strategy of “in situ catalytic polymerization and hot-pressing”. Benefiting from the multi-scale interactions (i.e., covalent bonds, hydrogen bonds, and physical interlocks) in hybrid structure, the MCP presents exceptional mechanical strength (≈101 MPa), stiffness (≈3.1 GPa), toughness (≈130 MJ m−3), and barrier properties (e.g., O2 0.0187 barrer, CO2 0.0264 barrer, and H2O 1.57 × 10−14 g cm cm−2 s Pa) that are higher than most reported bio-based materials and engineering plastics. Moreover, it also displays satisfactory multifunctionality with high reprocessability (90% strength retention after 5 recycling), UV resistance (blocking 85% UVA rays), and solvent-resistant properties. As a state-of-art high-performance and multifunctional material, the novel bio-based MCP nanocomposite offers a more sustainable alternative to petrochemical-based plastics in packaging and engineering material fields. More importantly, our catalysis-interfacial strengthening integration strategy opens a door for designing and constructing high-performance bio-based polyester materials in future.