「スマート」化学がネットワーク化されたゴム状材料のリサイクルを可能にする ‘Smart’ chemistry allows recycling of networked rubbery materials

2024-06-07 オークリッジ国立研究所(ORNL)

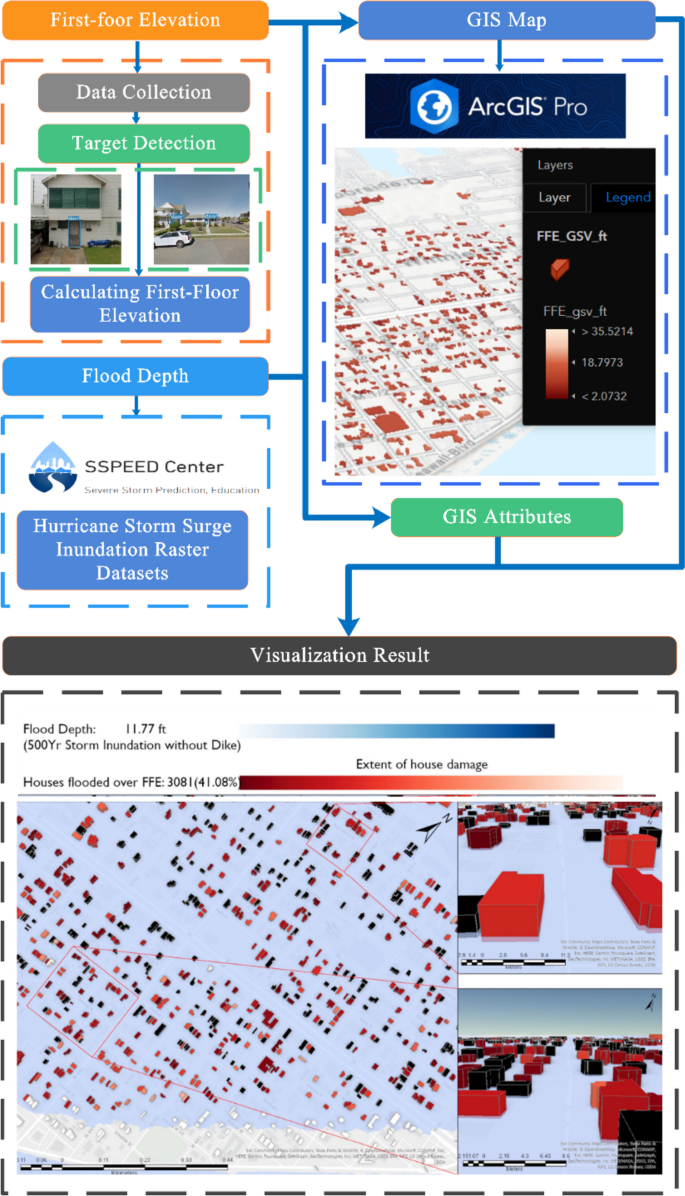

◆「100%バイオベースの原料を使用し、溶媒を使わない反応プロセスで『スマート』ポリマーを開発しました」と、テネシー大学大学院生のサーガン・ロヘワル氏は述べています。この材料は250度以上に加熱すると再成形可能になり、型に注入したり3Dプリントが可能です。次の研究では、これらのリサイクル可能なエラストマーの機械的性能と耐熱性を高める方法を調べる予定です。

<関連情報>

- https://www.ornl.gov/news/renewable-route-rapid-manufacturing

- https://pubs.rsc.org/en/content/articlelanding/2024/py/d3py01177a

リサイクル性を高めた高速で弛緩する持続可能な軟質ビトリマー Fast relaxing sustainable soft vitrimer with enhanced recyclability

Sargun Singh Rohewal,Nihal Kanbargi,Rebecca Young,Logan T. Kearney,Joshua T. Damron,Holly Hinton,Laurene Tetard and Amit K. Naskar

Polymer Chemistry Published:29 Jan 2024

DOI:https://doi.org/10.1039/D3PY01177A

Abstract

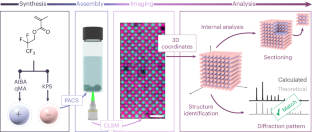

Vitrimers have been introduced to circumvent the lack of recyclability of traditional thermosets with permanent cross-linked structures, while preserving the advantages of structural stability and mechanical properties. The success of this lies in the successful incorporation of a robust networked structure to achieve reversible extensibility and toughness while preserving processability akin to thermoplastics. In this study, we report the synthesis of vitrimers utilizing 100% renewable and plant-based building blocks that exhibit transesterification exchange reaction (TER). The vitrimer was synthesized by solvent-free, high-shear reactive mixing of a biomass-derived lignin fraction enriched with carboxyl functionality and an epoxidized polyisoprene from natural rubber. The oxirane functionality in rubber reacts catalytically (zinc acetylacetonate) with carboxyl moieties in lignin to form esters at 180 °C. The ester linkages in the networked matrix undergo topological rearrangement upon heating above 180 °C, thus enabling (re)processability similar to thermoplastics. The material exhibits fast stress relaxation (characteristic relaxation time of <10 seconds) above 200 °C, which indicates the material’s potential for use in rapid manufacturing of components and their recycling. This approach provides a pathway for circular and value-added utilization of lignin and subsequent use as a matrix for reinforced composites.