2023-06-20 スウェーデン王立工科大学(KTH)

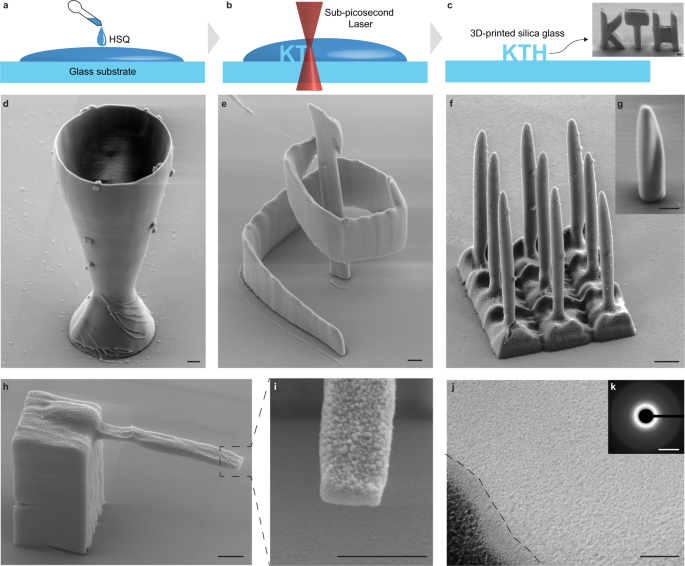

◆このデモンストレーションは、シリカガラス構造を簡単に作成するための新しい技術を示すことを目的としています。この技術は、医療機器やマイクロロボット、光ファイバーネットワークなど、さまざまな応用に活用できます。さらに、熱処理の必要性をなくすことでエネルギー消費を削減し、市販の材料を使用してシリカガラスを製造することができます。研究者たちは3Dガラスプリントが実用化に向けて重要な突破口であると信じています。

<関連情報>

- https://www.kth.se/en/om/nyheter/centrala-nyheter/researcher-3d-prints-world-s-smallest-wineglass-with-new-method-1.1263296

- https://www.nature.com/articles/s41467-023-38996-3

シリカガラスのサブマイクロメートル分解能での3次元プリンティング Three-dimensional printing of silica glass with sub-micrometer resolution

Po-Han Huang,Miku Laakso,Pierre Edinger,Oliver Hartwig,Georg S. Duesberg,Lee-Lun Lai,Joachim Mayer,Johan Nyman,Carlos Errando-Herranz,Göran Stemme,Kristinn B. Gylfason & Frank Niklaus

Nature Communications Published:07 June 2023

DOI:https://doi.org/10.1038/s41467-023-38996-3

Abstract

Silica glass is a high-performance material used in many applications such as lenses, glassware, and fibers. However, modern additive manufacturing of micro-scale silica glass structures requires sintering of 3D-printed silica-nanoparticle-loaded composites at ~1200 °C, which causes substantial structural shrinkage and limits the choice of substrate materials. Here, 3D printing of solid silica glass with sub-micrometer resolution is demonstrated without the need of a sintering step. This is achieved by locally crosslinking hydrogen silsesquioxane to silica glass using nonlinear absorption of sub-picosecond laser pulses. The as-printed glass is optically transparent but shows a high ratio of 4-membered silicon-oxygen rings and photoluminescence. Optional annealing at 900 °C makes the glass indistinguishable from fused silica. The utility of the approach is demonstrated by 3D printing an optical microtoroid resonator, a luminescence source, and a suspended plate on an optical-fiber tip. This approach enables promising applications in fields such as photonics, medicine, and quantum-optics.