2022-03-28 ペンシルベリア州立大学(PennState)

・電気化学的水素ポンプを用いて水素の分離と圧縮を行い、合成ガスと呼ばれる混合燃料ガスからの回収率は85%、従来の水ガスシフト反応器の出口流からの回収率は98.8%と、過去最高の数値となりました。

<関連情報>

- https://www.psu.edu/news/engineering/story/new-method-purifies-hydrogen-heavy-carbon-monoxide-mixtures/

- https://pubs.acs.org/doi/10.1021/acsenergylett.1c02853

水素分離に挑戦する電気化学ポンプ Electrochemical Pumping for Challenging Hydrogen Separations

Gokul Venugopalan,Deepra Bhattacharya, Evan Andrews, Luis Briceno-Mena, José Romagnoli, John Flake, and Christopher G. Arges

ACS Energy Lett. 2022, 7, XXX, 1322–1329 Publication Date:March 11, 2022

Abstract

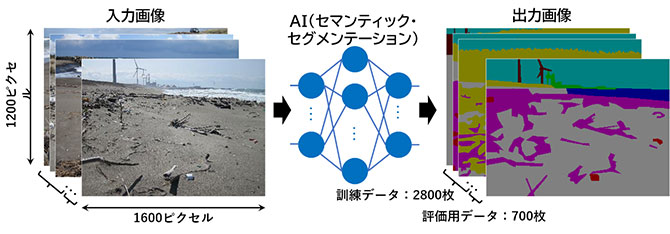

Conventional hydrogen separations from reformed hydrocarbons often deploy a water gas shift (WGS) reactor to convert CO to CO2, followed by adsorption processes to achieve pure hydrogen. The purified hydrogen is then fed to a compressor to deliver hydrogen at high pressures. Electrochemical hydrogen pumps (EHPs) featuring proton-selective polymer electrolyte membranes (PEMs) represent an alternative separation platform with fewer unit operations because they can simultaneously separate and compress hydrogen continuously. In this work, a high-temperature PEM (HT-PEM) EHP purified hydrogen to 99.3%, with greater than 85% hydrogen recovery for feed mixtures containing 25–40% CO. The ion-pair HT-PEM and phosphonic acid ionomer binder enabled the EHP to be operated in the temperature range from 160 to 220 °C. The ability to operate the EHP at an elevated temperature allowed the EHP to purify hydrogen from gas feeds with large CO contents at 1 A cm–2. Finally, the EHP with the said materials displayed a small performance loss of 12 μV h–1 for purifying hydrogen from syngas for 100 h at 200 °C.