2025-11-03 ペンシルベニア州立大学(PennState)

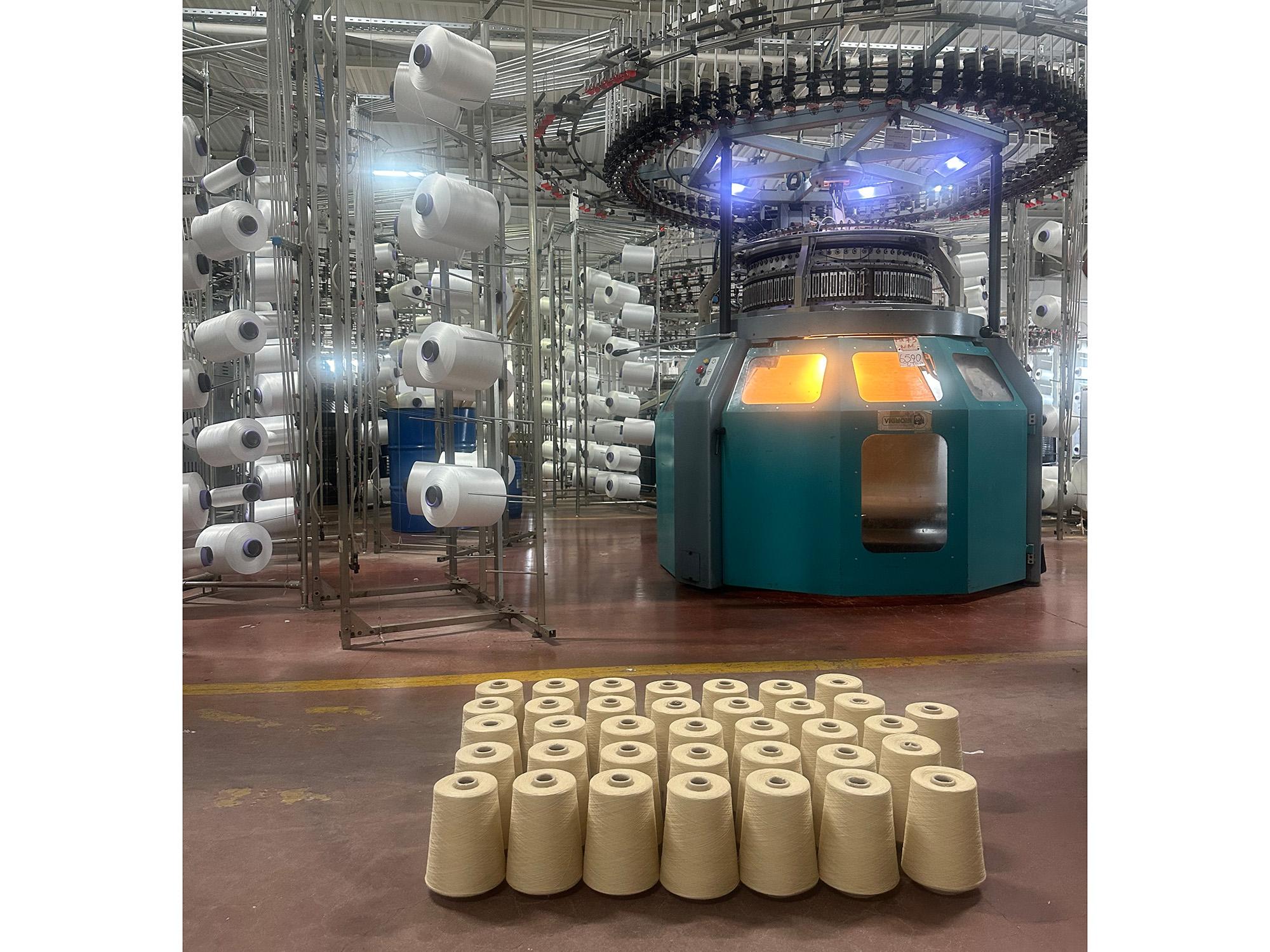

Researchers used the yeast byproduct of fermentation to make fiber. Credit: Provided by Melik Demirel/Penn State. All Rights Reserved.

<関連情報>

- https://www.psu.edu/news/research/story/fermentation-waste-used-make-natural-fabric

- https://www.pnas.org/doi/10.1073/pnas.2508931122

バイオ製造タンパク質繊維が持続可能な開発の達成に与える影響 Impact of biomanufacturing protein fibers on achieving sustainable development

Benjamin D. Allen, Baljit Ghotra, Birgit Kosan, +4 , and Melik C. Demirel

Proceedings of the National Academy of Sciences Published:November 3, 2025

DOI:https://doi.org/10.1073/pnas.2508931122

Significance

“Zero Hunger” requires innovative solutions that address the intricate relationships between food, water, and land use. One promising approach is to replace plant-based fibers, such as cotton, with fermentation-based fibers. By leveraging biomanufacturing, we can produce sustainable, high-performance fibers that do not compete with food crops for land, water, or nutrients. This shift would free up arable land for food production, enhance crop yields, and promote more efficient use of water resources. Moreover, fermentation-based fibers offer a reduced environmental footprint, lowering greenhouse gas emissions and mitigating the impact of textile production on ecosystems. By embracing biomanufacturing, we can make significant strides toward achieving the “Zero Hunger” goal, ensuring everyone can access nutritious food while promoting sustainable development goals.

Abstract

Biomanufactured fibers produced through fermentation processes provide a promising pathway to decouple textile production from agricultural land. This would free up arable land for food cultivation and contribute to the United Nations Sustainable Development Goal 2: Zero Hunger. Protein fibers from natural sources such as cocoon silk, collagen, and soy have attracted attention since the last century. However, commercial production declined with the rise of cheaper synthetic fibers and competition for food crops. Recently, renewed interest in protein fibers has emerged as a means to minimize plastic pollution, fueled by advances in fermentation, even though challenges related to yield, costs, and industrial spinning persist. Here, we studied a lyocell-based technique for spinning protein fibers using yeast biomass purified through an enzymatic method. We demonstrated that the enzymatic approach produces insoluble proteins that can be continuously spun for over 100 h of production time. Pilot-scale production exhibited stable spinning behavior with high viscosity and consistency quality. We achieved fiber fineness between 1.7 and 2.2 dtex, with strength values reaching 23 cN/tex, which is 50% higher than those of natural protein fibers such as wool. Life cycle assessment indicates that fermentation-based protein fibers require significantly less land and water than natural fibers while providing a reduced environmental footprint. Techno-economic analysis indicates a cost of $6 per kilogram at a production rate of 6,750 t annually. Adopting biomanufacturing-based protein fibers marks a significant advancement toward a future where fiber needs are fulfilled without compromising the planet’s capacity to nourish its growing population.