2025-09-24 アルゴンヌ国立研究所(ANL)

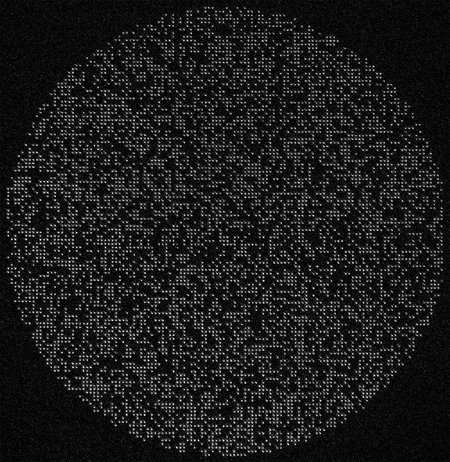

Scanning transmission electron microscopy images of 3D-printed 316H stainless steel before (a) and after (b and c) two heat treatment techniques. Red arrows indicate nano oxides, which greatly impact the steel’s response to heat treatment. (Image by Argonne National Laboratory.)

<関連情報>

- https://www.anl.gov/article/argonne-scientists-investigate-3dprinted-steels-for-use-in-nextgeneration-nuclear-reactors

- https://www.sciencedirect.com/science/article/pii/S0264127525001121

- https://www.sciencedirect.com/science/article/abs/pii/S0921509325002722

レーザー粉末床溶融結合法による316Hステンレス鋼の微細構造と特性に対する溶解焼鈍効果の定量化 Quantification of solution annealing effects on microstructure and property in a laser powder bed fusion 316H stainless steel

Lin Gao, Srinivas Aditya Mantri, Xuan Zhang

Materials & Design Available online: 4 February 2025

DOI:https://doi.org/10.1016/j.matdes.2025.113692

Highlights

- Recovery happens at 1150 °C or lower while recrystallization happens at 1200 °C.

- Dislocations recover rapidly during the beginning stage of solution annealing.

- Lack of nucleation sites and presence of nano oxides hinder recrystallization.

- Dislocations and oxides contributes to strength increase in LPBF materials.

- A creep model incorporating threshold stress explains the minimum creep rates.

Abstract

Solution annealing (SA) is an effective way to mitigate microstructural heterogeneity and to optimize mechanical performance of alloys manufactured by laser powder bed fusion (LPBF). In this study, a comprehensive and quantitative understanding of the recovery and recrystallization processes in the SA temperature range of LPBF 316H stainless steel is provided using results from analytical electron microscopy and in-situ high-energy synchrotron x-ray scattering. The profound effect of dislocation structures and secondary phase particles on mechanical performance, particularly under tension and creep conditions, is rationalized using deformation models that incorporate microstructural inputs. This study, for the first time, quantifies the broad effect of nano oxide inclusions on dislocation recovery kinetics, on grain growth and recrystallization kinetics, and on tension strength and creep resistance. The fundamental differences between the LPBF and the conventional wrought materials are revealed. The findings address critical questions in post-build processing of AM materials and pave the way for their rapid qualification for high temperature applications.

レーザー粉末床溶融結合法で製造されたオーステナイト系ステンレス鋼合金709の微細構造の発達と引張挙動に対する堆積後焼鈍の影響 Influence of post deposition annealing on the microstructural evolution and tensile behavior of austenitic stainless-steel alloy 709 made by laser powder bed fusion

S.A. Mantri, X. Zhang, W.-Y. Chen

Materials Science and Engineering: A Available online: 13 February 2025

DOI:https://doi.org/10.1016/j.msea.2025.148054

Abstract

Structural materials used in the next generation nuclear reactors or other advanced energy systems are often required to withstand higher operating temperatures for a longer service life. Alloy 709 (A709), a Nb-containing and N-stabilized Fe-25Ni-20Cr austenitic stainless steel, has been recommended for high-temperature reactor constructions due to the better performance over the baseline Type 316H stainless steel. In the current manuscript, for the first time, the microstructure evolution and tensile behavior of an A709 made by laser powder bed fusion (LPBF) is discussed. The as deposited and heat treated LPBF alloys are compared with a reference wrought alloy. Owing to the chemical segregation and a higher number of dislocations, the LPBF materials show a significantly higher density of precipitates formed during high temperature treatments when compared to the wrought samples. This is reflected when looking at the tensile properties, both at room and elevated temperatures, where LPBF samples show higher strengths compared to wrought materials.