2025-09-15 アルゴンヌ国立研究所(ANL)

<関連情報>

積層造形における急速凝固時の変位の進展 Evolution of dislocations during the rapid solidification in additive manufacturing

Lin Gao,Yan Chen,Xuan Zhang,Sean R. Agnew,Andrew C. Chuang & Tao Sun

Nature Communications Published:20 May 2025

DOI:https://doi.org/10.1038/s41467-025-59988-5

Abstract

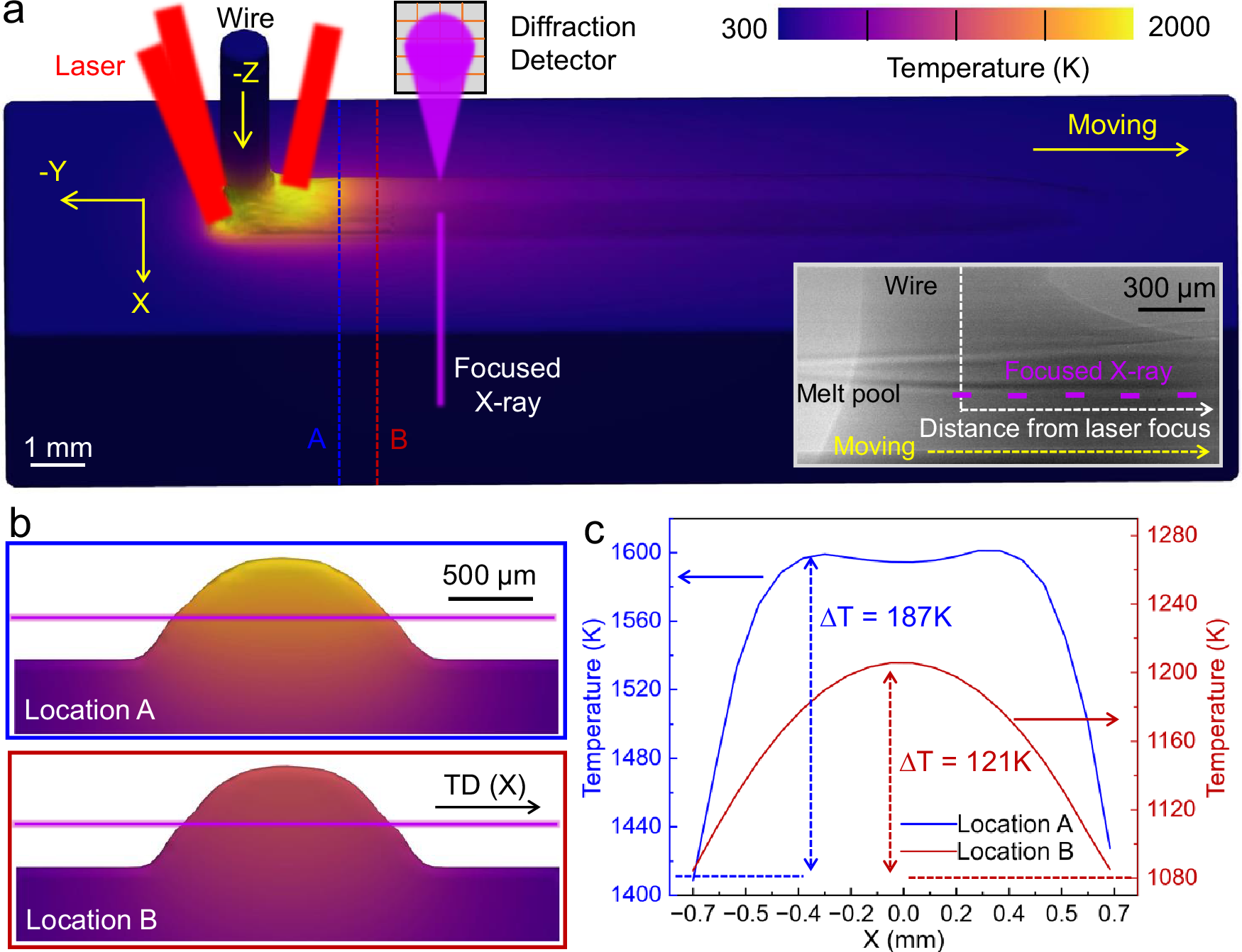

Materials processed by fusion-based additive manufacturing (AM) typically exhibit relatively high dislocation densities, along with cellular structures and elemental segregation. This representative structural feature significantly influences material performance; however, post-mortem microstructure characterizations of AM materials cannot capture the dynamic evolution of dislocations during the manufacturing process, thereby offering limited mechanism-based guidance for further advancing AM techniques and facilitating the qualification and certification of AM products. In this study, we conduct operando high-energy synchrotron X-ray diffraction experiments on wire-laser directed energy deposition of 316 L stainless steel. Through a unique configuration, our operando synchrotron experiments semi-quantitatively probe the dislocation density in solid phases and their dynamic changes during solidification and subsequent cooling. By integrating this advanced synchrotron technique with multi-physics simulation, in-situ neutron diffraction, and multi-scale electron microscopy characterization, our mechanistic study aims to elucidate the effects of rapid cooling and subsequent thermal cycling on the dislocation generation and evolution.