2025-07-16 量子科学技術研究開発機構

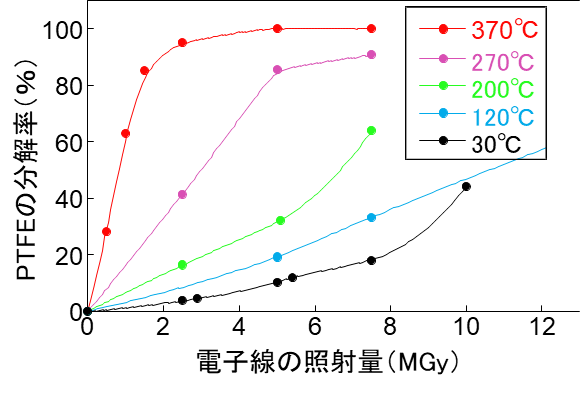

図1:空気中で熱したPTFEに電子線を照射したときの分解率

<関連情報>

- https://www.qst.go.jp/site/press/20250716.html

- https://pubs.acs.org/doi/10.1021/acsomega.4c11623

- https://www.sciencedirect.com/science/article/abs/pii/S0969806X25005213

ポリテトラフルオロエチレンの熱分解挙動に及ぼすニッケル触媒と放射線の協同効果 Cooperative Effects of Ni Catalyst and Radiation on Thermal Decomposition Behavior of Poly(tetrafluoroethylene)

Hao Yu,Akira Idesaki,Kimio Yoshimura,and Yasunari Maekawa

ACS Omega Published: June 29, 2025

DOI:https://doi.org/10.1021/acsomega.4c11623

Abstract

This study investigated the impact of a Ni-complex catalyst on the thermal decomposition of irradiated poly(tetrafluoroethylene) (PTFE) through thermogravimetric analysis and spectroscopic techniques. This catalyst, comprising Ni and NiO particles on a microporous SiO2/Al2O3 support, was incorporated into PTFE powder via mechanical grinding. The Ni-loaded PTFE exhibited nearly 50% weight loss at temperatures 370–400 °C, which is 153–123 °C lower than the decomposition temperature of untreated PTFE (523 °C). The thermal stability of PTFE declines significantly above its melting point. Following electron beam irradiation, approximately half of the irradiated PTFE residue was degassed at relatively low temperatures (100–140 °C), likely due to thermal reactions of the decomposed products or chemically modified PTFE components. FTIR and XPS analyses of the Ni-loaded PTFE residue revealed that both the Ni catalyst and irradiation promoted C–F bond cleavage along with the formation and breakdown of oxidized PTFE fragments and fluorocarbons (CnF2nOx). Additionally, the Ni catalyst enhanced PTFE oxidation, promoting the conversion of oxidized PTFE moieties to gaseous products such as CO, CO2, and COF3. Furthermore, the catalyst supplies oxygen for oxidation and decomposes unoxidized PTFE components during irradiation and subsequent thermal treatment. The combined effects of the Ni catalyst and irradiation notably reduced the thermal decomposition temperature of PTFE, showing great potential for expansion to applications involving the recycling of all per- and polyfluoroalkyl substances.

電子線照射によるPTFEの分解に及ぼす温度の影響 Effects of temperature on the decomposition of PTFE induced by electron beam irradiation

Hao Yu, Akira Idesaki, Kimio Yoshimura, Yue Zhao, Yasunari Maekawa

Radiation Physics and Chemistry Available online: 3 June 2025

DOI:https://doi.org/10.1016/j.radphyschem.2025.113029

Highlights

- PTFE weight loss increased with temperature—from 18 % at 30 °C to 91 % at 270°C—at a dose of 7.5 MGy and a rate of 1.0 kGy/s.

- At 370 °C, a 5.0 MGy dose completely converted PTFE powder into gaseous components.

- The primary product of PTFE gaseous decomposition was oxidized fluorocarbon (CnF2nOx).

- High-temperature irradiation enlarged PTFE crystallite size from 21 ± 2 nm to 37 ± 5 nm.

Abstract

The effect of temperature on the irradiation-induced decomposition of polytetrafluoroethylene (PTFE), a representative fluorocarbon polymer, was investigated to improve the energy efficiency of the recycling process. The weight loss of PTFE was 18 %, 33 %, 64 %, and 91 % by the irradiation with a dose of 7.5 MGy (dose rate:1.0 kGy/s) at 30 °C, 120 °C, 200 °C, and 270 °C, respectively. During the electron beam (EB) irradiation of PTFE powders under an oxygen atmosphere, a greater weight loss of PTFE was observed at higher irradiation temperatures. At 370 °C, PTFE powder is completely converted to gaseous components with an absorbed dose of 5.0 MGy; the primary product was identified as an oxidized fluorocarbon (CnF2nOx). A lower dose rate (0.1 kGy/s) reduced the required absorbed dose for PTFE decomposition to 80 % level. Post-irradiation analyses of the PTFE residues using TGA, SEM-EDX, and FT-IR consistently showed that higher irradiation temperatures accelerated the production of oxidized fluorocarbons and further oxidized gaseous products evaporating from the PTFE residue. XRD analysis showed that high-temperature irradiation also increased the crystallite size to 37 ± 5 nm after irradiation at 270 °C, which is nearly double the size of non-irradiated PTFE (21 ± 2 nm). High-temperature irradiation significantly accelerated the oxidation and weight loss of PTFE, offering a promising method for enhancing the energy efficiency of PTFE recycling.