2025-06-24 米国国立再生可能エネルギー研究所(NREL)

<関連情報>

- https://www.nrel.gov/news/detail/program/2025/nrel-publishes-method-for-recycling-all-components-in-carbon-fiber-composites

- https://www.nature.com/articles/s41586-025-09067-y

エポキシ-アミン炭素繊維強化ポリマーリサイクルのためのアセト分解 Acetolysis for epoxy-amine carbon fibre-reinforced polymer recycling

Ciaran W. Lahive,Stephen H. Dempsey,Sydney E. Reiber,Ajinkya Pal,Katherine R. Stevenson,William E. Michener,Hannah M. Alt,Kelsey J. Ramirez,Erik G. Rognerud,Clarissa L. Lincoln,Ryan W. Clarke,Jason S. DesVeaux,Taylor Uekert,Nicholas A. Rorrer,Katrina M. Knauer & Gregg T. Beckham

Nature Published:04 June 2025

DOI:https://doi.org/10.1038/s41586-025-09067-y

Abstract

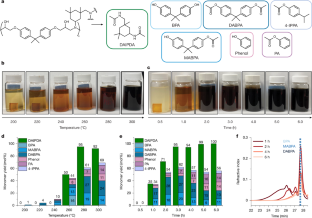

Carbon fibre-reinforced polymers (CFRPs) are used in many applications in the global energy transition, including for lightweighting aircraft and vehicles and in wind turbine blades, shipping containers and gas storage vessels1,2,3,4. Given the high cost and energy-intensive manufacture of CFRPs5,6,7, recycling strategies are needed that recover intact carbon fibres and the epoxy-amine resin components. Here we show that acetic acid efficiently depolymerizes both aliphatic and aromatic epoxy-amine thermosets used in CFRPs to recoverable monomers, yielding pristine carbon fibres. Deconstruction of materials from multiple sectors demonstrates the broad applicability of this approach, providing clean fibres from 2 h reactions. The optimal conditions were scaled to 80.0 g of post-consumer CFRPs, and demonstrative composites were fabricated from the recycled carbon fibres, which were recycled two more times, maintaining their strength throughout. Process modelling and techno-economic analysis, with feedstock cost informed by wind turbine blade waste generation8, indicates this method is cost effective, with a minimum selling price of US$1.50 per kg for recycled carbon fibres whereas life cycle assessment shows process greenhouse gas emissions around 99% lower than virgin carbon fibre production. Overall, this approach could enable recycling of industrial CFRPs as it provides clean, mechanically viable recycled carbon fibres and recoverable resin monomers from the thermoset.