2025-02-13 カーディフ大学

The team says their innovative catalytic technology has the potential to play a pivotal role in advancing the green hydrogen economy and contributing to the world’s carbon neutrality goals.

<関連情報>

- https://www.cardiff.ac.uk/news/view/2896934-scientists-create-hydrogen-with-no-direct-co2-emissions-at-source

- https://www.science.org/doi/10.1126/science.adt0682

CO2排出ゼロの水素製造のための熱触媒改質 Thermal catalytic reforming for hydrogen production with zero CO2 emission

Mi Peng, Yuzhen Ge, Rui Gao, Jie Yang, […], and Ding Ma

Science Published:13 Feb 2025

Editor’s summary

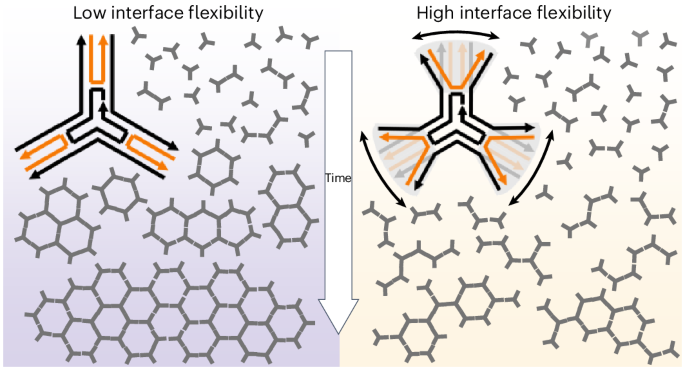

A thermal catalytic process converts ethanol and water into hydrogen and acetic acid at low temperatures with near-zero carbon dioxide production, unlike the conventional methane-reforming process used to make hydrogen. Peng et al. developed a catalyst with a high density of atomically dispersed platinum and iridium species on reactive α-molybdenum carbide that facilitates reforming at the metal-support interfaces. The absence of larger metal nanoparticle surfaces avoids unwanted carbon–carbon bond cleavage. —Phil Szuromi

Abstract

Carbon-neutral hydrogen production is of key importance for the chemical industry of the future. We demonstrate a new thermal catalytic route for the partial reforming of ethanol into hydrogen and acetic acid with near-zero carbon dioxide emissions. This reaction is enabled by a catalyst containing a high density of atomic Pt1 and Ir1 species supported on a reactive alpha-molybdenum carbide substrate, achieving a hydrogen production rate of 331.3 millimoles of hydrogen per gram catalyst per hour and an acetic acid selectivity of 84.5% at 270°C, and is therefore more energy-efficient compared with standard reforming. Techno-economic analysis of partial ethanol reforming demonstrates the potential profitability for operation at an industrial scale, presenting the opportunity to produce hydrogen and acetic acid with a substantially reduced carbon dioxide footprint.