2024-07-02 パデュー大学

パデュー大学の材料工学者たちは、コバルト、鉄、ニッケル、チタンをアルミニウムに導入し、超高強度かつ高い塑性変形性を持つアルミニウム合金を開発しました。この新しい合金は、従来のものに比べて、積層製造(3Dプリンティング)に適しており、航空宇宙や自動車産業での利用が期待されています。従来の高強度アルミニウム合金は、製造過程での熱割れが問題でしたが、この新技術はそれを克服し、900メガパスカル以上の強度と優れた塑性を実現しました。

<関連情報>

- https://www.purdue.edu/newsroom/2024/Q3/purdue-researchers-fabricate-ultrastrong-aluminum-alloys-for-additive-manufacturing/

- https://www.nature.com/articles/s41467-024-48693-4

ナノスケールの金属間化合物を含む超高強度変形性アルミニウム合金の積層造形 Additive manufacturing of an ultrastrong, deformable Al alloy with nanoscale intermetallics

Anyu Shang,Benjamin Stegman,Kenyi Choy,Tongjun Niu,Chao Shen,Zhongxia Shang,Xuanyu Sheng,Jack Lopez,Luke Hoppenrath,Bohua Peter Zhang,Haiyan Wang,Pascal Bellon &Xinghang Zhang

Nature Communications Published:15 June 2024

DOI:https://doi.org/10.1038/s41467-024-48693-4

Abstract

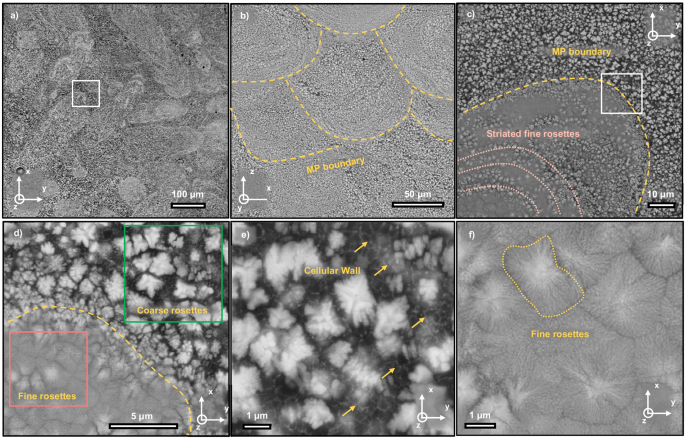

Light-weight, high-strength, aluminum (Al) alloys have widespread industrial applications. However, most commercially available high-strength Al alloys, like AA 7075, are not suitable for additive manufacturing due to their high susceptibility to solidification cracking. In this work, a custom Al alloy Al92Ti2Fe2Co2Ni2 is fabricated by selective laser melting. Heterogeneous nanoscale medium-entropy intermetallic lamella form in the as-printed Al alloy. Macroscale compression tests reveal a combination of high strength, over 700 MPa, and prominent plastic deformability. Micropillar compression tests display significant back stress in all regions, and certain regions have flow stresses exceeding 900 MPa. Post-deformation analyses reveal that, in addition to abundant dislocation activities in Al matrix, complex dislocation structures and stacking faults form in monoclinic Al9Co2 type brittle intermetallics. This study shows that proper introduction of heterogeneous microstructures and nanoscale medium entropy intermetallics offer an alternative solution to the design of ultrastrong, deformable Al alloys via additive manufacturing.