2024-03-28 スイス連邦工科大学ローザンヌ校(EPFL)

<関連情報>

- https://actu.epfl.ch/news/3d-images-reveal-link-between-crack-complexity-a-2/

- https://www.nature.com/articles/s41567-024-02435-x

クラックフロント形状の複雑さが脆性固体の靭性を高める Complexity of crack front geometry enhances toughness of brittle solids

Xinyue Wei,Chenzhuo Li,Cían McCarthy & John M. Kolinski

Nature Physics Published:22 March 2024

DOI:https://doi.org/10.1038/s41567-024-02435-x

Abstract

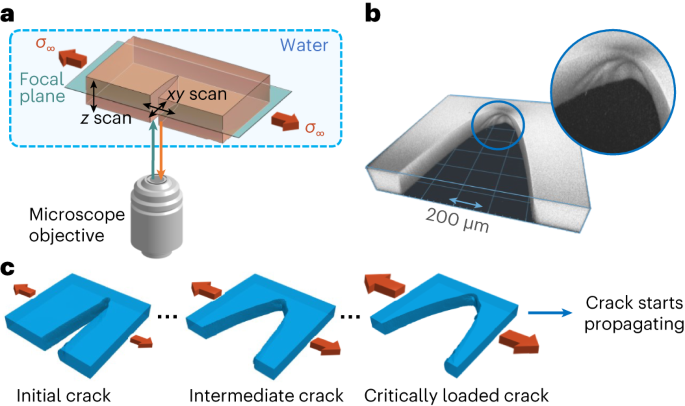

Brittle solids typically fail by growth and propagation of a crack from a surface flaw. This process is modelled using linear elastic fracture mechanics, which parameterizes the toughness of a material by the critical stress intensity factor, or the prefactor of the singular stress field. This widely used theory applies for cracks that are planar, but cracks typically are not planar, and instead are geometrically complex, violating core tenets of linear elastic fracture mechanics. Here we characterize the crack tip kinematics of complex crack fronts in three dimensions using optical microscopy of several transparent, brittle materials, including hydrogels of four different chemistries and an elastomer. We find that the critical strain energy required to drive the crack is directly proportional to the geodesic length of the crack, which makes the sample effectively tougher. The connection between crack front geometry and toughness has repercussions for the theoretical modelling of three-dimensional cracks, from engineering testing of materials to ab-initio development of novel materials, and highlights an important gap in the current theory for three-dimensional cracks.