2023-12-14 デンマーク工科大学(DTU)

◆この技術は、現在のプラスチック製造に使用されている化石ベースの化学物質に代わるものであり、グリーンな代替手段を提供します。耐久性の向上により、CO2電解は商業化の可能性が高まり、社会のグリーンな移行に寄与する可能性があります。 CO2電解は複雑でコストがかかるプロセスですが、今回の研究で明らかになった耐久性の課題への対処により、技術の将来的な実用化が期待されます。

<関連情報>

- https://www.dtu.dk/english/news/all-news/from-co2-to-green-chemicals-researchers-are-one-step-closer

- https://www.nature.com/articles/s41929-023-01034-y#citeas

高濃度CO電解用膜-電極接合デバイスにおける耐久性の課題の特定と緩和 Identifying and alleviating the durability challenges in membrane-electrode-assembly devices for high-rate CO electrolysis

Qiucheng Xu,Sahil Garg,Asger B. Moss,Marta Mirolo,Ib Chorkendorff,Jakub Drnec & Brian Seger

Nature Catalysis Published:28 September 2023

DOI:https://doi.org/10.1038/s41929-023-01034-y

Abstract

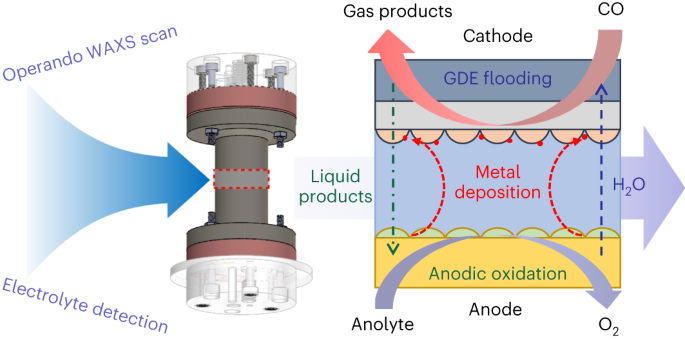

CO electrolysis (COE) has emerged as an important alternative technology to couple with other sustainable techniques for transitioning towards a carbon-neutral future. A large challenge for the deployment of high-rate COE is the limited durability of membrane-electrode assembly (MEA) devices. Here, by using an operando wide-angle X-ray scattering technique and monitoring the change of electrolyte, we identified several degradation mechanisms of the MEA during high-rate COE. Cathodic gas-diffusion electrode (GDE) flooding and Ir contaminants (crossover from anode) are two main issues causing excessive hydrogen evolution, which can be partly alleviated by increasing the polytetrafluoroethylene content in GDEs and using an alkaline stable Ni-based anode. During long-term stability, the dynamic evolution of anolyte became the main issue: the pH would continuously drop due to cathodic acetate formation and anodic ethanol oxidation. By compensating for this issue, we maintained a Faradaic efficiency of C2+ products at more than 70% for 136 hours.